|

Lisa's 1977 FJ40 Rear 3rd Gets Rebuilt (new bearings and 370 gears)

|

|

(41 BIG pics loading)

|

|

AUGUST 17 2016

|

|

|

Lisa has a classic 1977 FJ40 and needs to switch from the 411 gears to 370 ratio.

Eventually, the FJ40 will be fully restored in Capri Blue (T310). In the Spring time the word is.

|

|

|

|

The rear diff was pulled out and sent my way.

Good idea with the 4 jackstands.

|

|

|

|

We discussed whether it is better to send both or maybe one at a time.

In the interest of safety and stability, it was decided to leave 2 tires on the ground

and send one at a time.

|

|

|

|

|

The interior looks super.

|

|

|

|

|

5 days later, 3 boxes arrive for me. The RCV box is mine :) awesome product by the way.

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

Very well packaged up. Master install kit shown on far right.

|

|

|

|

|

Items are organized and sorted.

|

|

|

|

The 40 has a semi-floater in the back so these items did not have to be sent to me.

In the upper right, the crosspin has to be removed for the thick c-clips to be inserted in the case.

|

|

|

|

|

A pinion depth shim of .014" will be placed under the new race.

|

|

|

|

|

Making sure the race is fully seated.

|

|

|

|

|

All looks good.

|

|

|

|

|

New outer race is also pressed in.

|

|

|

|

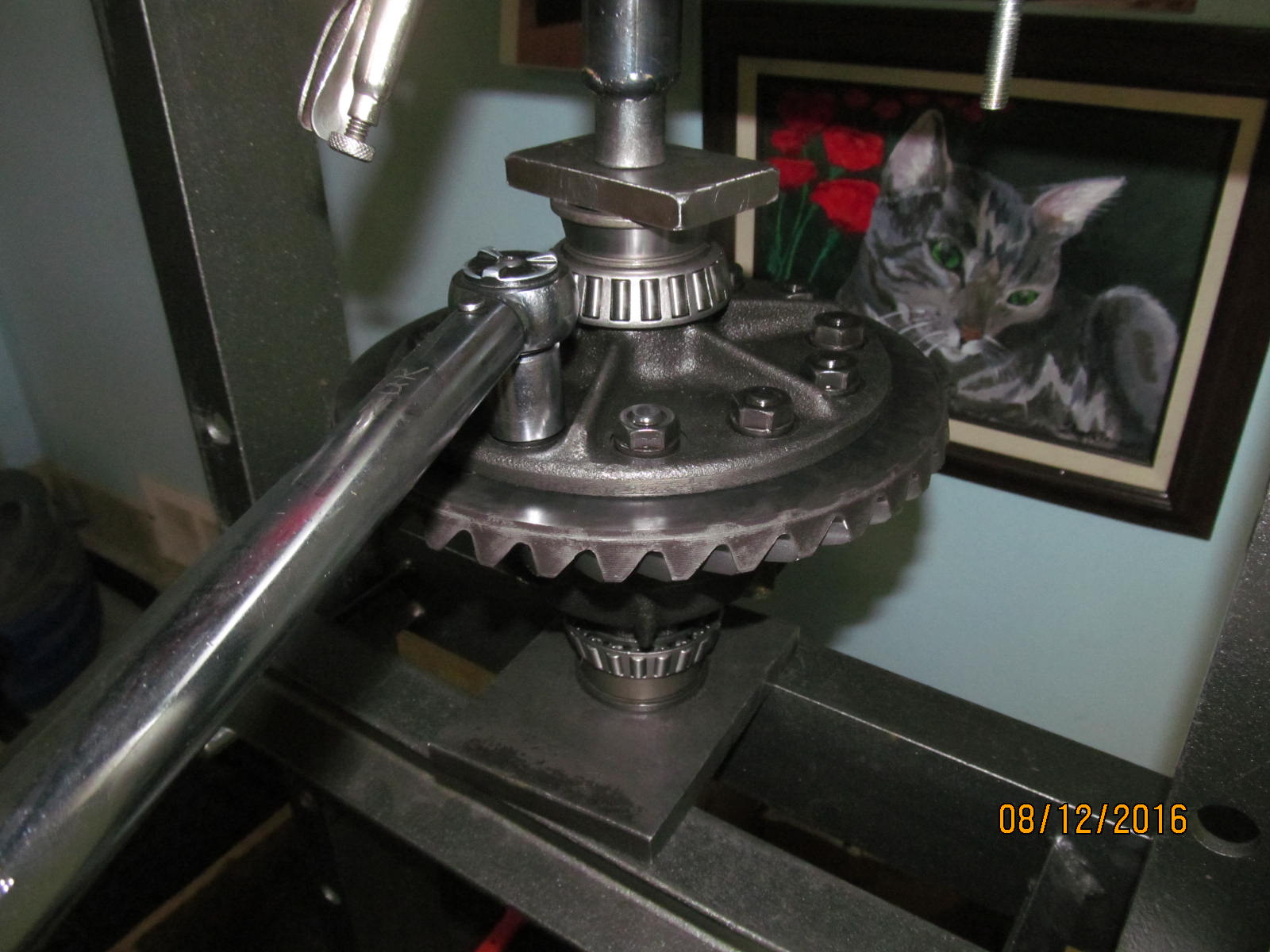

The 370 pinion gets a new bearing with no pinion shim (it's under the race).

Portrait pic of my other outdoorsy cat "Bullseye" as painted by my sister.

|

|

|

|

|

The pinion is loaded into the diff carrier.

|

|

|

|

|

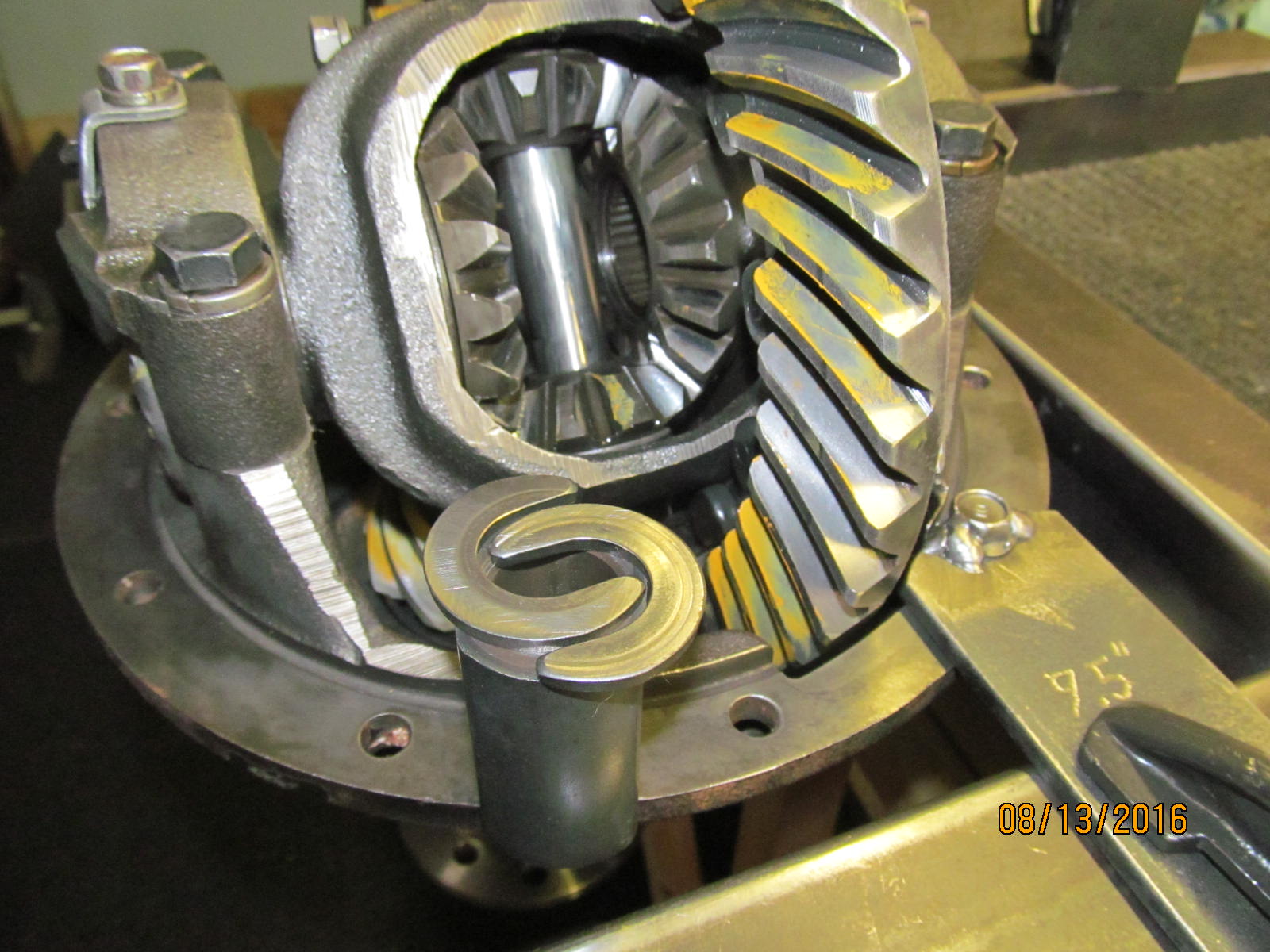

And now to load the 370 ring gear onto the carrier.

|

|

|

|

|

Surface checks show no unusual burrs or bumps.

|

|

|

|

|

Using the 12 bolts to get the perfect vertical alignment, the ring gear can be tapped down.

|

|

|

|

|

81 ft/lb on all 12 bolts per the fsm.

|

|

|

|

|

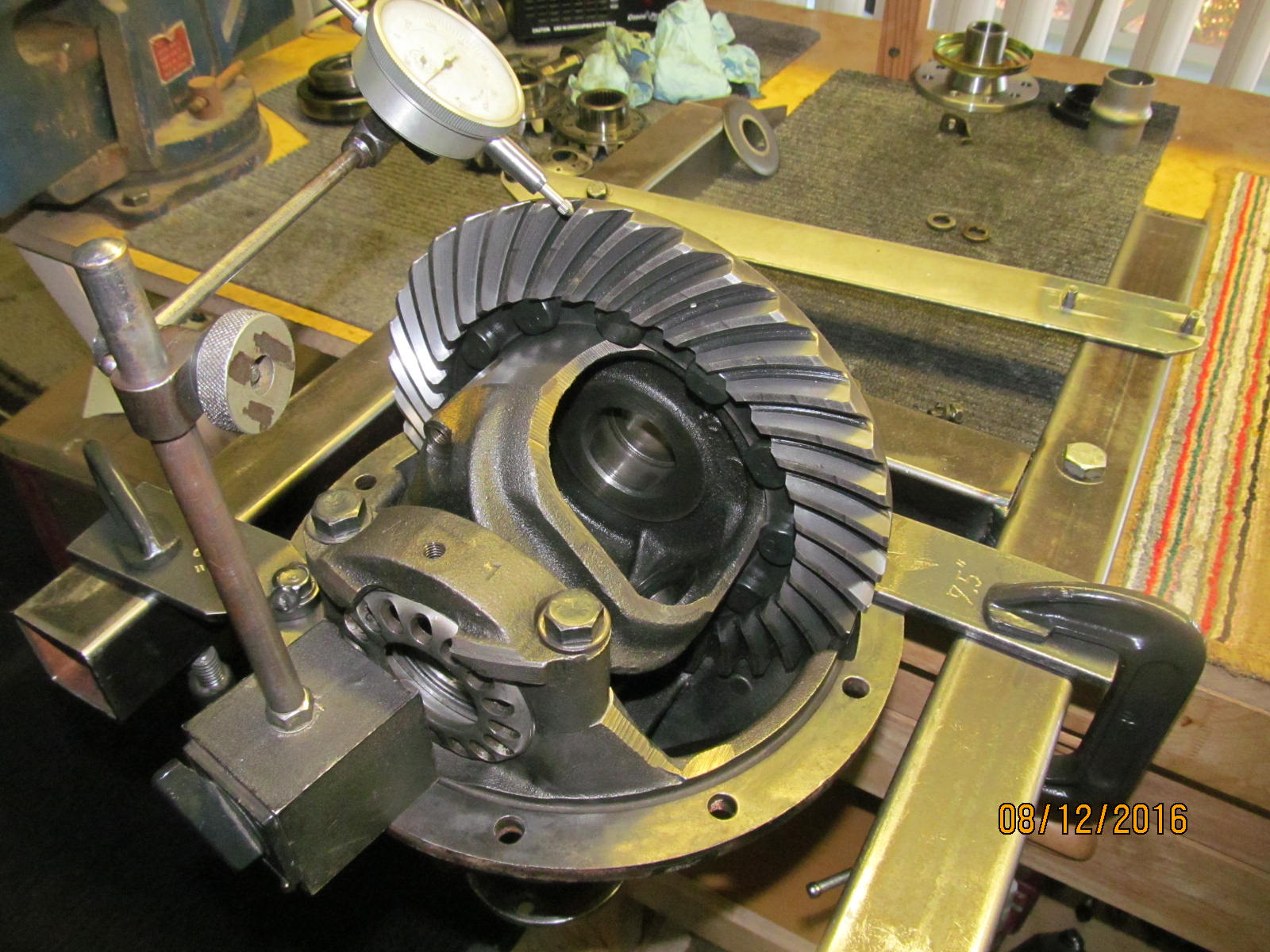

Some carrier bearing preload and a quick backlash adjustment....

|

|

|

|

|

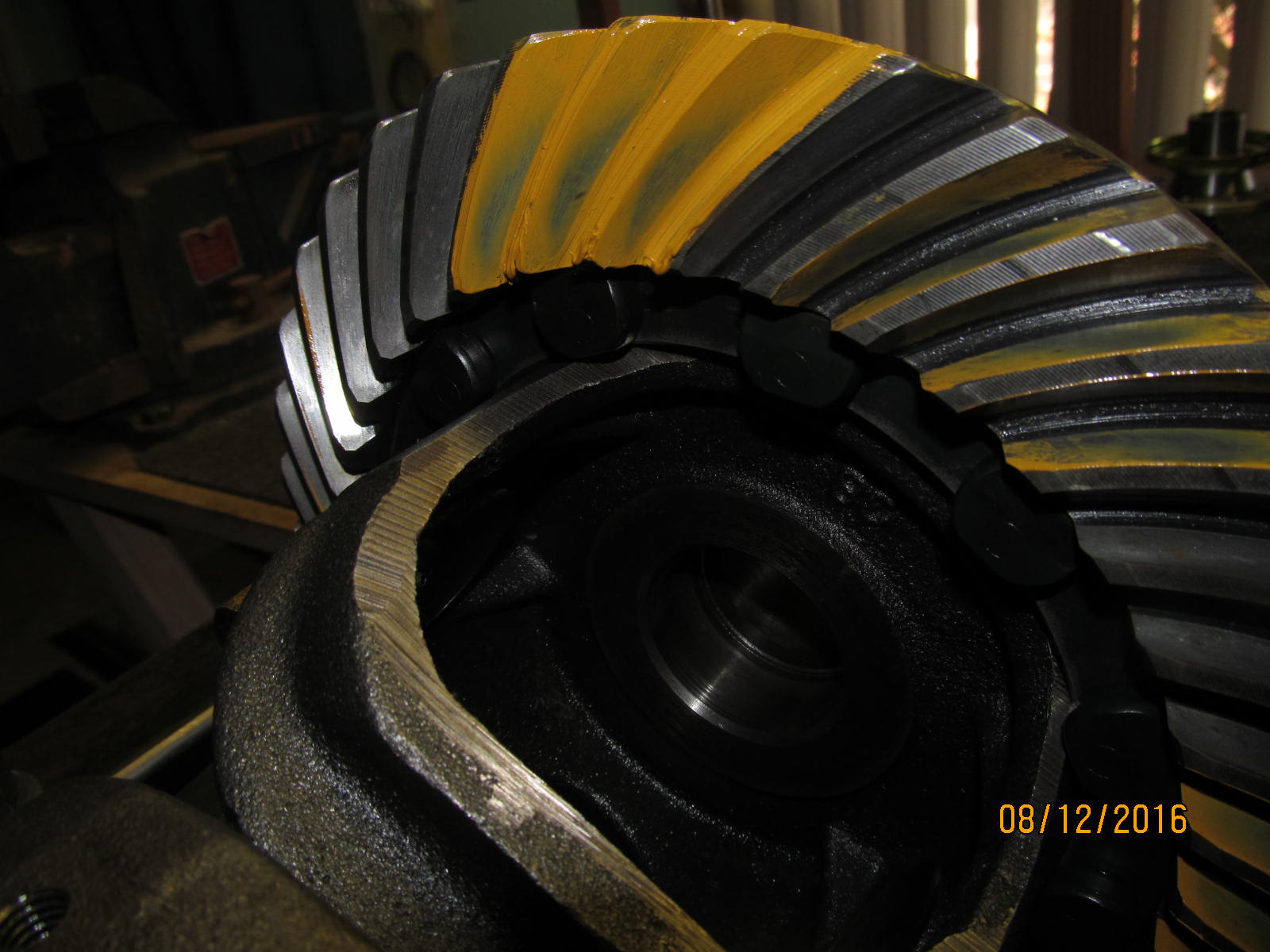

...and the pattern is too deep here on the drive side.

|

|

|

|

|

Coast.

|

|

|

|

|

Remove and re-shimming from 014" to 011".

|

|

|

|

|

Much better

|

|

|

|

|

Coast.

|

|

|

|

|

The comet tail is heading towards the center(good).

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

Now that proper pinion depth has been established, time for a final teardown to install the crush sleeve.

|

|

|

|

|

,,,,,

|

|

|

|

|

Last chance to splash fresh gear oil on the outer bearing...

|

|

|

|

|

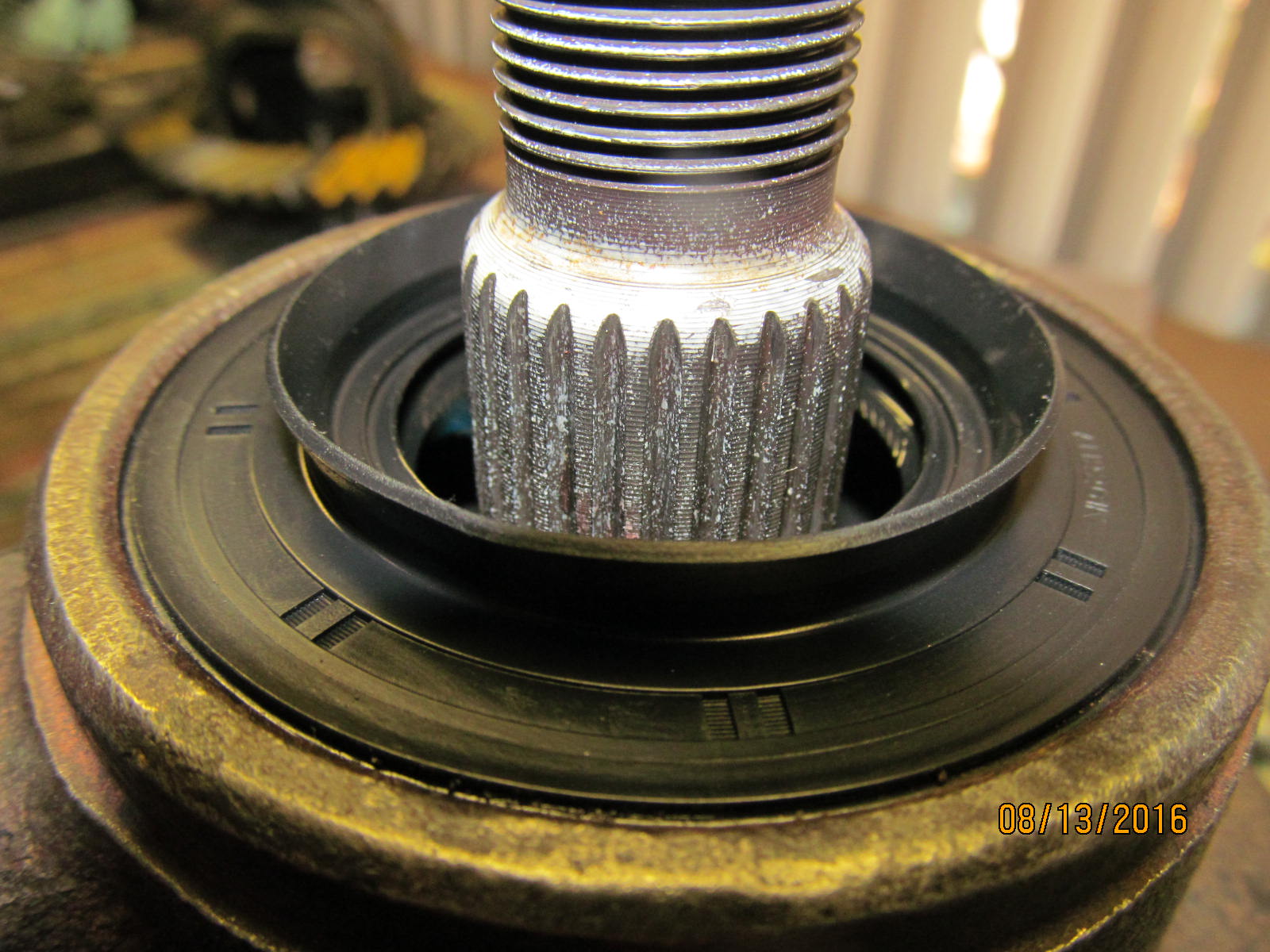

New pinion seal goes on now.

|

|

|

|

|

A properly installed seal.

|

|

|

|

|

The pinion nut was gradually tightened until 10 in/lb of pinion preload start torque was noted.

|

|

|

|

|

DING a dent and this completes the pinion end of things.

|

|

|

|

|

Ring gear assembly is mounted in place and the bearing caps are set to 70 ft/lb

|

|

|

|

Both wheel adjusters are tightened incrementally and carrier bearing preload is dialed in with careful

attention to backlash readings.

|

|

|

|

|

The combined pre-load(PPL + CBPL) was right at 18 in/lb so all is good now.

|

|

|

|

|

Now the 2 lock tabs can be torqued down to 10+ ft/lb

|

|

|

|

This block gets installed after the 3rd is set in the axle housing and AFTER the axles are

in with the c-clips secured in place.

|

|

|

|

|

The crosspin bolt is left loose for that reason....

|

|

|

|

|

.....whoever installs this 3rd will have to remove the crosspin one last time to get the block in.....

|

|

|

|

|

....along with the c-clips.

|

|

|

|

|

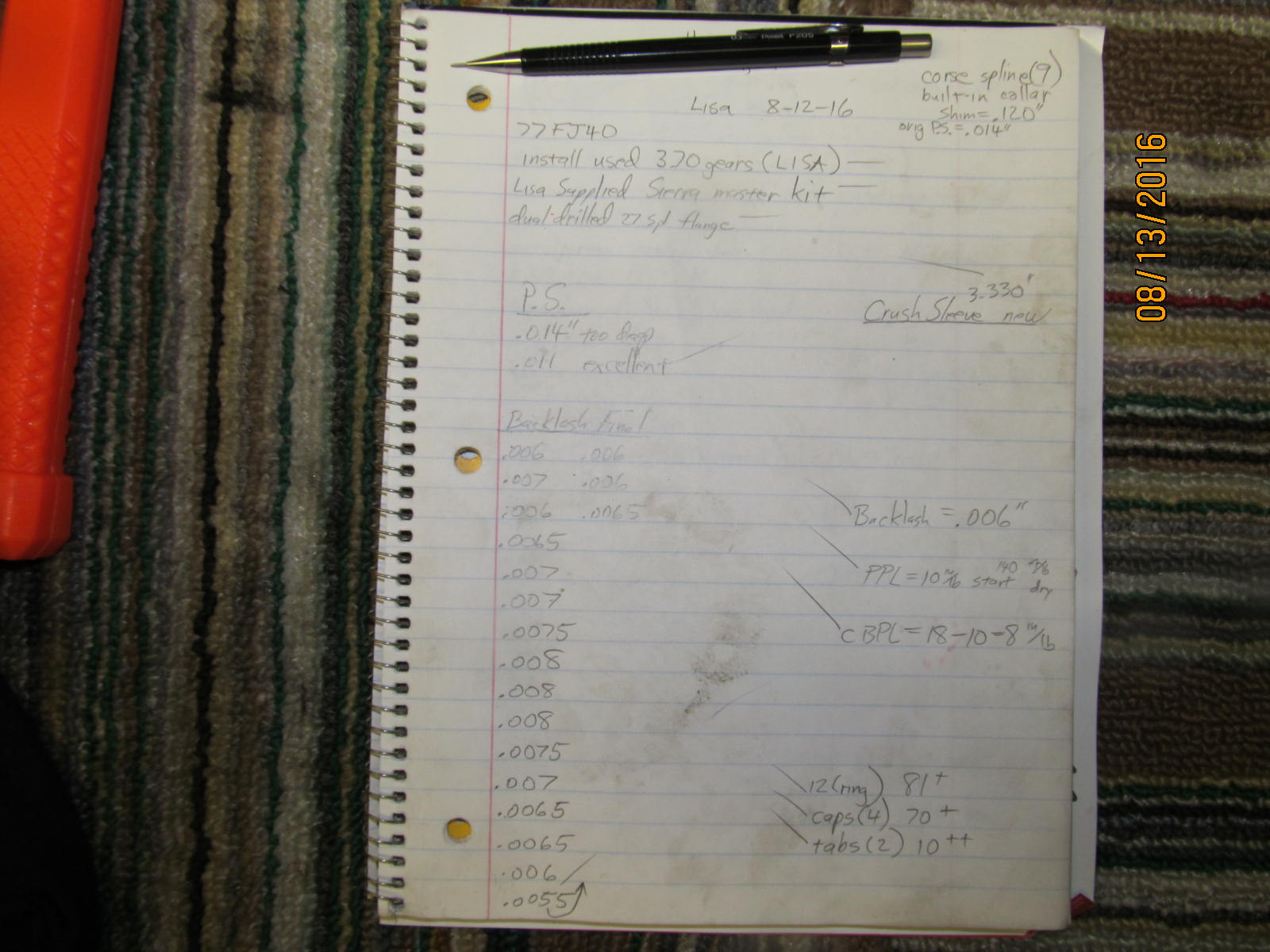

Notes of Lisa's completed 3rd.

|

|

|

|

|

A pair of double corrugated boxes makes for a strong box to return the diff in.

|

|

|

|

|

Clear packaging tape keeps it legal with the fedex/ups/usps folks.

|

|

|

|

|