|

Loren is local to me and lives up near New River. Elmo is the name of the rig. Loren was wheelin' one day and

found an Elmo doll just laying in the trail. Loren remembers the 1996 Elmo craze and how some were selling for 1000

dollars and more at the time. Now he gets a front seat on every trail ride :)

|

|

|

Lower Woodpecker near Florence, AZ.

|

|

|

|

|

Loran is not a madman on the throttle and was using finesse while climbing a nasty series of boulders when a loud BANG!

came from the front end. This is a quality US GEAR. This one probably broke due to an installation issue...see below.

|

|

|

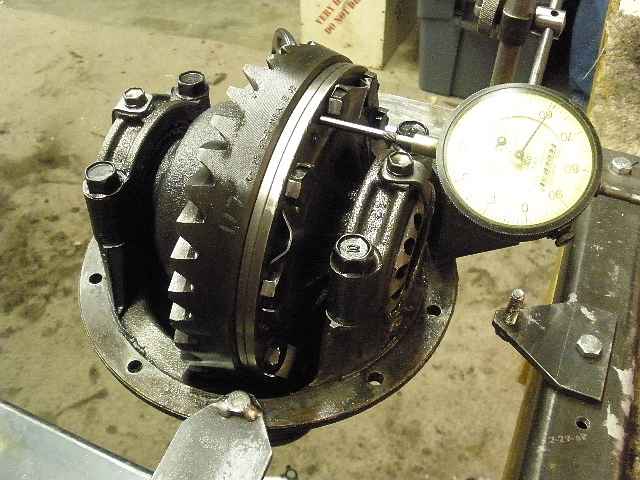

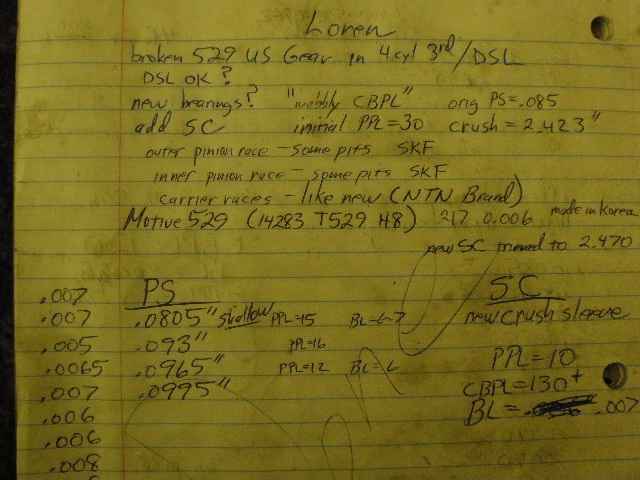

Front 3rds see relatively little use compared to rears. Bearings and pre-loads should last a long, long time in front end

applications with hubs that can be dis-engaged. This one not only had zero CBPL, it was actually 'wobbly' in the axial direction

as measured in the above pic. Slop measured at .010" ....no wonder the poor ring gear exploded.

|

|

|

Markings on the broken gear...

|

|

|

A good quality gear....US GEAR.

|

|

|

The Detroit SoftLocker will need to be inspected. First, remove the ring.

|

|

|

Some close-ups of the tooth damage.

|

|

|

............

|

|

|

A firm left hand holds the spring loaded Detroit while the last allenhead is removed.

|

|

|

..............

|

|

|

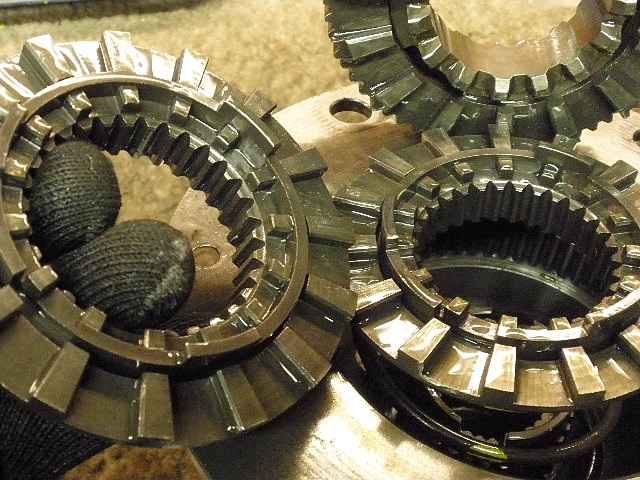

These are the 15 teeth that have been known to shear off (when an axle snaps) and these appear just fine.

I could see a benefit to cry-treating the guts of a Detroit....

|

|

|

The other set of 15 are also all there. No wear or rounded teeth are visible. This locker is just fine.

|

|

|

..............

|

|

|

With the case out now I can measure the PPL and it was unusually high at 30 in/lbs.

|

|

|

The pinion is pressed out and the old crush will be replaced with a new one.

|

|

|

This was an unusual find....the big inner pinion bearing had a crack...

|

|

|

...that extended the full length of the main body.

|

|

|

This is the cracked bearing. I'm wondering if the bearing cracked at the same time as the big initial BANG....that

bearing was aweful close to the shockwave of the carnage.

|

|

|

This new Timken will replace it.

|

|

|

The new race is pressed in.

|

|

|

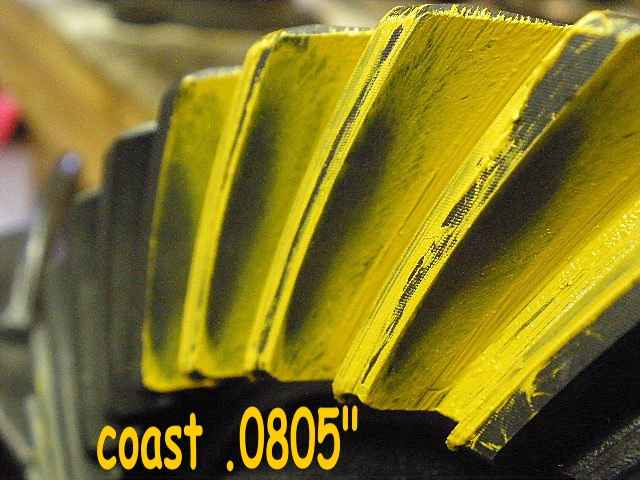

The new Timken is pressed on with the starter shim of .0805".

|

|

|

The pinion is loaded up with no crush sleeve. The pinion nut is tightened until about 10 in/lb of drag is measured.

|

|

|

Back to the ring gear end of things, surfaces are filed and no irregularities are found.

|

|

|

Red loctite and 75 ft/lbs.

|

|

|

This is very shallow.

|

|

|

......

|

|

|

The pinion is pressed out.

|

|

|

Press bearing off....

|

|

|

...press bearing back on with a new shim of .093".

|

|

|

It's still shallow.

|

|

|

...................

|

|

|

Re-shimmed....and it's still a touch shallow.

|

|

|

.......

|

|

|

Even the pinion suggests that a little more shim would be in order.

|

|

|

.003" added and now it's spot on.

|

|

|

So, now that proper depth has been established, the pinion is pushed out one last time to add the

new crush sleeve in.

|

|

|

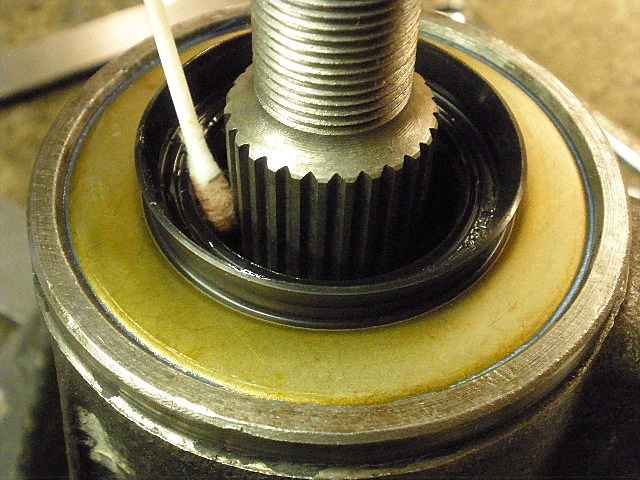

Smothering the tiny compression spring in a thick grease keeps it from popping off while the seal is being banged on.

|

|

|

Gear oil is applied to the seal surface to prevent a dry start-up.

|

|

|

The Loctite actually makes it a little tougher to crush the sleeve...

|

|

|

...but that's why I have the 3 foot cheater bar.

|

|

|

PPL is good now.

|

|

|

Ding!

|

|

|

Aluminum based anti-sieze is liberally applied to all of the threads on the bearing caps.

|

|

|

The caps can be tightened to the full 70~75 ft/lb spec and the adjuster wheels should turn very easy.

|

|

|

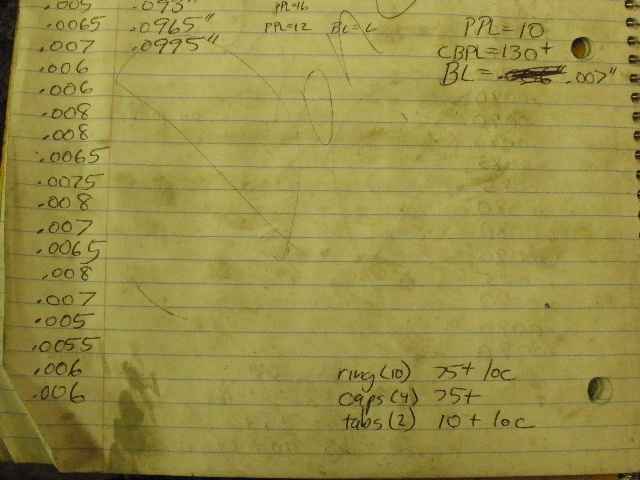

Backlash was set to .007". The torque wrench verified that there was 130 ft/lb on the wheels.....effectively,

that means that there is really 13 inch/pounds of actual carrier bearing drag.

|

|

|

Backlash is measured on every other tooth and recorded on the paperwork.

|

|

|

Loctite on the lock-tab bolts and 10 ft/lb.

|

|

|

One more final pattern check and beautiful.

|

|

|

....

|

|

|

These Motive 529 gears came from Korea.

|

|

|

specs used and the date are added to the ring.

|

|

|

...............

|

|

|

...............

|

|