|

Marc's out of El Segundo, California and sent both diffs for a 488 re-gear. Solid

collars and new master kits were included. This link shows the front 4 cylinder 3rd being set-up.

|

|

|

The carrier bearings slipped on loosely so 2 drops of this sleeve retainer compound would lock the

bearings in place.

|

|

|

Compression was used overnight to allow the compound to set-up.

|

|

|

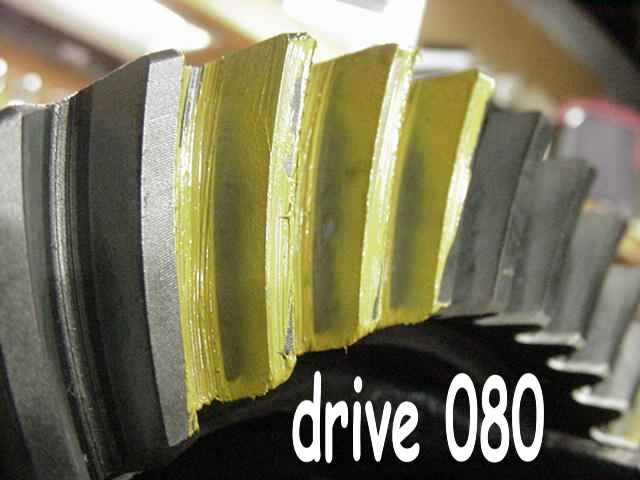

.056" for the solid collar shim value turned out to be the right value

to give 15inch/pounds of pinion drag. The 080 pinion shim was not so lucky...

I had to change it twice again to get the correct depth.

|

|

|

The Park Tool TW-1 makes pinion pre-load measurements so easy. As many times as I've done this, I

still use the tool for every install.

|

|

|

Red Loctite 272 and 75 ft/lb of torque.

|

|

|

deep

|

|

|

deep

|

|

|

A complete teardown has to be done to change out the pinion shim. This tool makes quick work of removing

the inner pinion bearing.

|

|

|

The bearing is actually pulled off by the 360 degree capture of the race cage itself.

|

|

|

Better but still deep.

|

|

|

deep

|

|

|

right on the money.

|

|

|

good.

|

|

|

Getting the BL set to 007 and getting the CBPL at 150 ft/lbs is a little time consuming because, half the time, it's

generally done with the bearing cap bolts about 1/2 turn loose and numerous hits with the hammer to set the

bearings. Then when the bolts are tightened, the BL changes a little....then loosen the bolts and crank the

tension in the direction needed to bring the BL in spec. and hope it falls in the range desired.

|

|

|

Sometimes, when rapping the seal in with a hammer, the tiny circular spring on the underside of the seal falls out. Always

eyeball down the center to see if it did. This has happened twice to me that I know of.

Here, I'm using some gear oil on the seal lip to prevent a dry start-up.

|

|

|

The confidence level is very high that the pinion will stay tight...forever. Solid collar is

the only way to go. 200 ft/lbs and red Loctite #272 keep it tight.

|

|

|

A little black paint and it's heading back to Marc :)

|

|