|

|

|

|

|

|

Matt, from Bakersfield CA, shipped me two 4-cyl 3rds that have the old style RD01 ARBs(45mm journals) in them already. The plan is to break-down the ARBs and convert them both to RD23(50mm journals) for installation in a rear V6 carrier and a brand new HP carrier from Allpro. This link is only for the hi-pinion install. 529 Nitro Gears from JustDifferentials.com are also going in. |

|

Old style 4 cylinder RD01. |

|

serial numbers on the case. |

|

The arb is removed from the 4 cyl carrier. |

|

... |

|

As received from Allpro. |

|

... |

|

... |

|

Everything is here to do the change-over. |

|

This is all the stuff sent from ARB to convert it for use in a V6 carrier. |

|

Here's the master install kit. The 4 bearings have been cryo treated for superior life. |

|

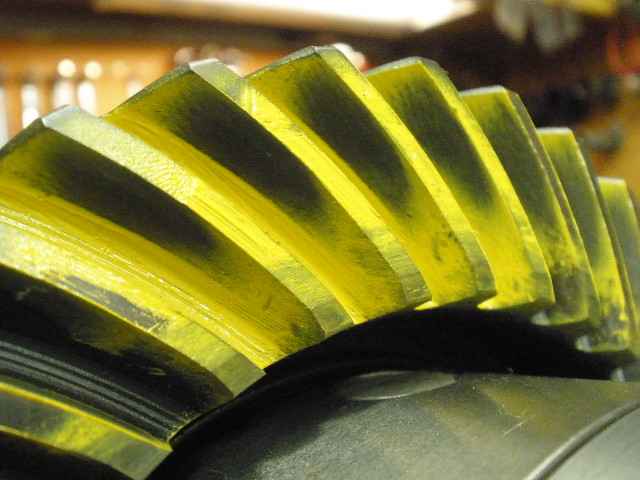

The RD01 has the smaller 45mm journals in order to fit the 4 cylinder carrier bearings. The ends (lid and flange) will be replaced to allow 50mm V6 bearings to fit. Shown is the 529 reverse cut Hi-pinion Nitro Gears that have been both HEAT and CRYO treated. |

|

The old oem pinion flange will be replaced with a new multi-drilled flange. |

|

... |

|

The old one had a fair groove in it and I was concerned about a potential leak. |

|

The new one is....new :) |

|

The old flange cap is removed. |

|

The splined sidegear is next. |

|

Now to flip it over and remove the arb lock tabs. Red loctite will be used instead of these tabs upon re-assembly. |

|

An 8mm 12 point socket easily takes off the 6 bolts that hold the cylinder cap on. |

|

The orange piston seal can be seen on the left...the sidegear and plastic piston are on the right. |

|

The 3 soft metal retaining pins come out easy. |

|

The 3 cross-shafts can now be removed. |

|

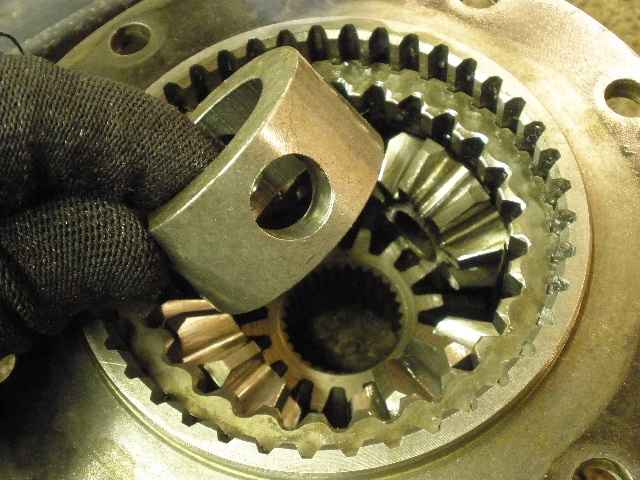

The spider block now comes out... |

|

...and so do the 4 spiders with the worn thrust washers. |

|

Last, but not least, the sidegear and thrust washer. |

|

That pretty much does it but I was curious what the return springs looked like that keep the plastic piston in the unlocked position with so much determination. |

|

To me, it feels like it takes 80 pounds of physical force to push the piston down(about 1/2") into the locked position. |

|

A simple twist, a light pull, and it comes off. |

|

These are the 4 springs that return the arb to the unlocked position when the air is released. |

|

This clutch gear is what actually couples and locks it together. |

|

This main center section is now fully stripped down and now to put it all back together with new thrust washers and end caps. |

|

New thrust washers for the pinions (spiders)... |

|

...new thrust washers for the sidegears. |

|

This looks like the US GEAR logo on this sidegear. |

|

Grease helps hold the thrust washers in place. |

|

With some fumbling, the pinions can be aligned and the 3 cross-shafts will slip through... |

|

...and success was eventually accomplished. |

|

The 3 retainer pins just drop in place with gravity. |

|

Some new oil for the thrust washer. |

|

This is the old cylinder cap with the soft orange piston seal. |

|

The new design involves an upgraded cap with a 'bonded' piston seal. |

|

Now the cylinder cap covers it. |

|

Red loctite is applied to the threads. |

|

... |

|

New gear oil and a new thrust washer on this splined sidegear. Look closely and notice that I did not notice the

old washer was still on the sidegear. |

|

One more check...the spiders all turn very smoothly. |

|

Sidegear is layed in place... |

|

The flange cap is lined up... |

|

hmmm....a slight gap. Then I discovered that I had 2 thrust washers on that sidegear. Problem corrected and then the lid went on all the way and the sidegear would actually turn when I reached my finger inside the journal. All was good now. |

|

The ring gear required a little coaxing. |

|

The flange cap was fitted in place and red loctite was applied liberally to the 10 ring gear bolts. |

|

Cross-tightened with 75 ft/lbs. |

|

These are the parts I replaced to convert the rd01 to an RD23(45mm to 50mm). |

|

The carrier bearings were a very tight fit but the press made easy work of it. |

|

The new races(cryo treated) were also pressed on. |

|

... |

|

The protective coating on the pinion was burned off during the heat treatment process but it left some residue. |

|

... |

|

I will press on the new cryo bearing with a .080" shim for the first try. |

|

... |

|

I can install the pinion now without any sort of crush or solid collar and tighten the pinion nut until about 10~15 in/lb is reached for PPL. |

|

The ARB case is installed and the bearing caps are tightened down in preparation for a pattern check. Minimal carrier bearing preload is set and backlash is set in the ballpark of .008" for this preliminary check. |

|

A nice, wide load bearing but it's too deep...need to remove some pinion shim. |

|

coast |

|

The pinion tooth looks to be favoring the outer edges. Shallow on the pinion means deep on the ring tooth. |

|

The load bearing is favoring the edges...that means shallow here and implies deep on the ring tooth. |

|

I pulled it apart and removed .0035" worth of pinion shim. This is overall good. The patterns are varying from tooth to tooth which I have no control on. |

|

The coast is good. |

|

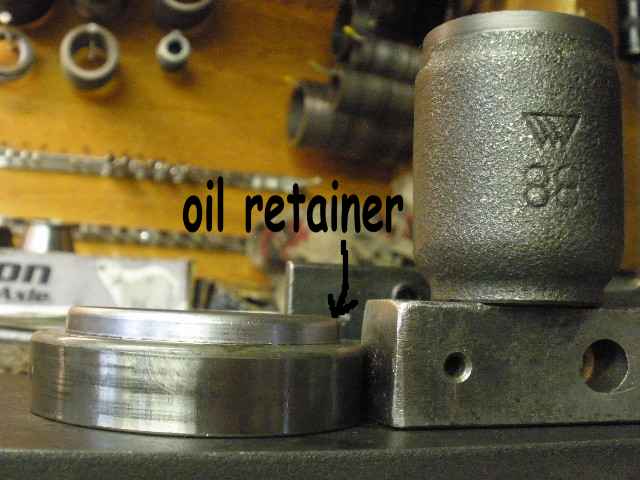

Because of the low shoulder design of the solid collar, I had to clearance the inside of the oil retainer. |

|

I made use of an oem Toyota solid collar because of the bell shape. |

|

Now the solid collar will not rub on the retainer. |

|

It took 4 tries to get the right shim thickness for the collar. |

|

Now the shop flange can be removed and the new seal installed. |

|

A light coating of gear oil on the flange underside will minimize the added drag of the seal's dust cover. |

|

RTV was added to the flange splines to prevent any possible oil from sneaking up the splines. Loctite on the pinion nut is added insurance. |

|

By tightening the nut extra tight, I was able to get the PPL preload close to the upper limits. |

|

Ding the nut and this end is done. |

|

The ARB case is installed and the bearing caps are temporarily bolted in place. The oil seal assembly was lubed up and carefully wiggled in place. |

|

The soft copper line is gently routed in the neatest possible fashion. |

|

... |

|

It's alot easier to route the copper without the brass bulkhead hindering things. |

|

The copper line is nicely centered. |

|

With the copper line routed and cut to length, now the ARB case can be permanently installed. Anti-seize is generously splashed on all the threads. |

|

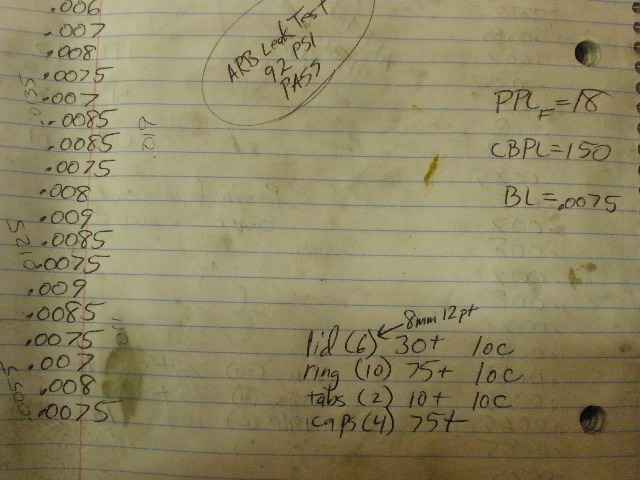

The 4 cap bearing bolts are tightened to 75 ft/lb and the wheel adjusters are tightened to 150 ft/lbs while guiding the backlash to .007 or .008". Remember from my earlier links that 150 ft/lbs on the wheels translates into 15 in/lbs of actual CBPL carrier bearing preload. |

|

120 in/lbs on the lock tabs....with loctite. |

|

One more pattern check...looks even better than before. |

|

coast is good. |

|

This is my compressor that I use to air up my tires after the trail rides. It also sees ARB leakdown test duty. |

|

... |

|

Did not budge a smidge even after 30 minutes. |

|

Through the case, I can see the locker teeth engage.... |

|

...and dis-engage when the air was released. |

|

Just a final BL check on every other tooth for about 21 measurements. |

|

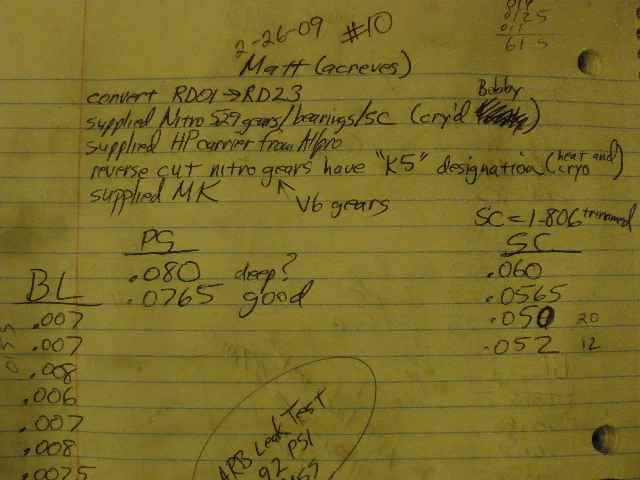

Some documentation... |

|

...some more documentation in the form of the notes I took during the rebuild process. |

|

Done. |

|