|

Max sent me his rear 8.4" 3rd from El Rito, New Mexico. This plastic tote is a much more secure method

than the 5 gallon plastic buckets that I used in the distant past. The ring gear tends to punch holes right through the 5

gallon buckets.

|

|

|

Even though there was extra room for things to move all around , all was ok here.

|

|

|

I dug out the carrier bearings (90366-51001) and the Truetrac.

|

|

|

That left the 3rd that was well wrapped burrito style in the tote.

|

|

|

```

|

|

|

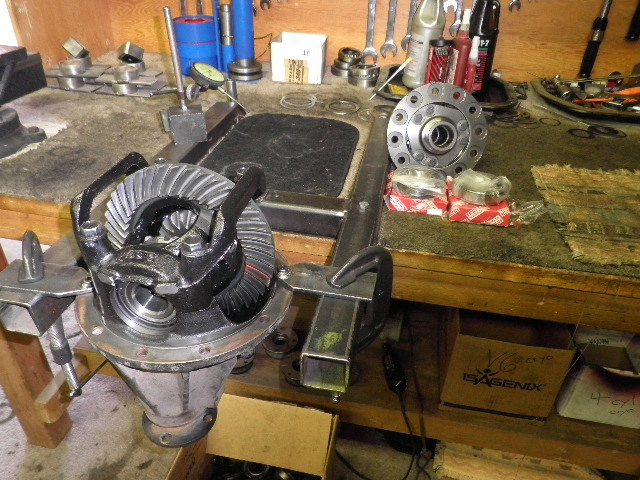

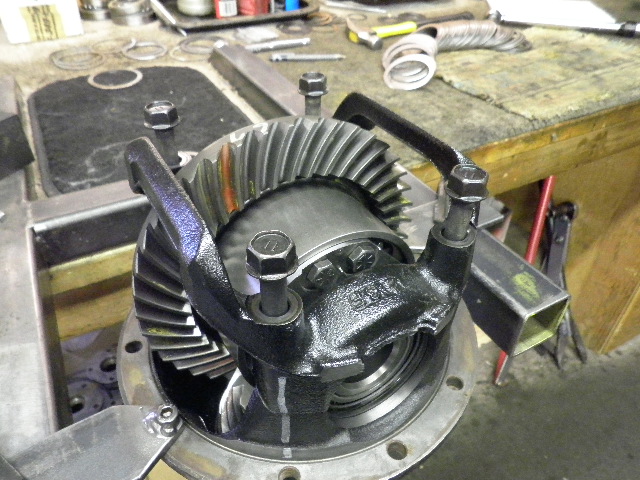

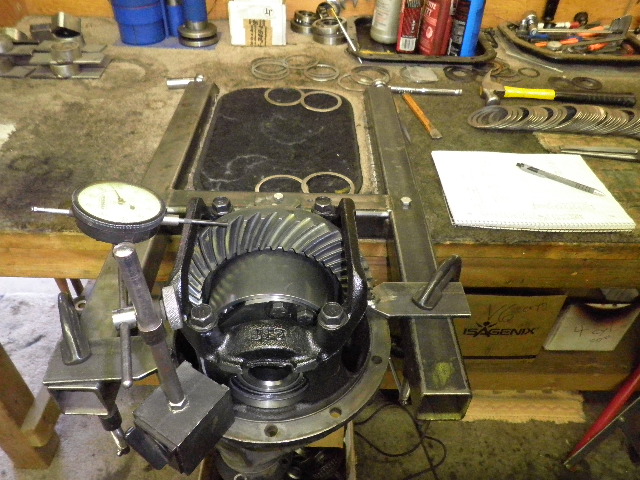

The 8.4 is secured to the fixture.

|

|

|

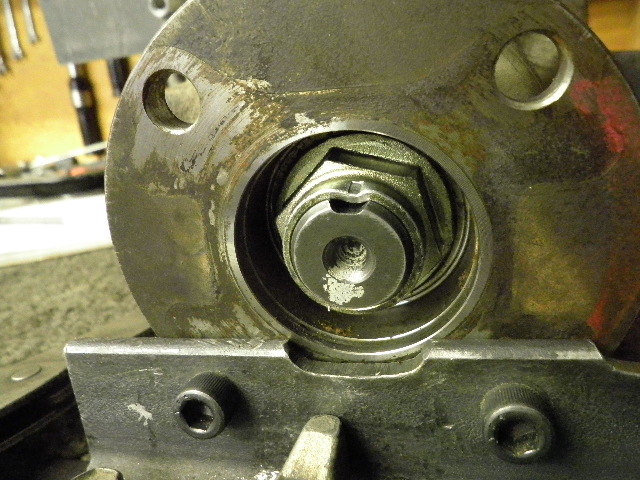

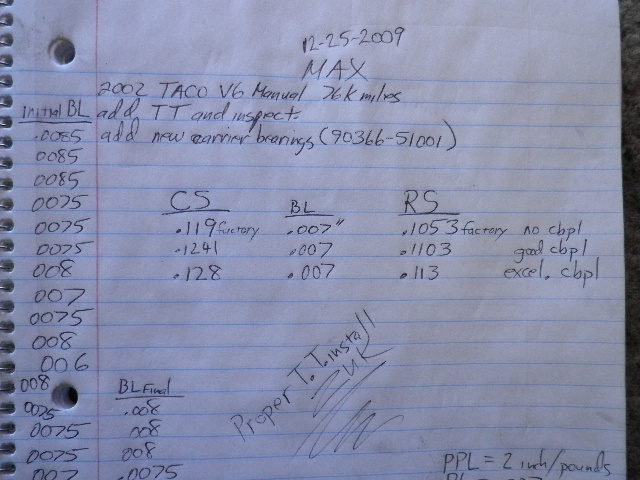

76,000 miles....and, as can be expected, the pinion pre-load is all but gone.

|

|

|

Carrier bearing pre-load (CBPL) is low. I've seen far worse but when I get done, this will be much better.

|

|

|

Before the teardown, I recorded the BL on about every other tooth and the average looked like .0075".

|

|

|

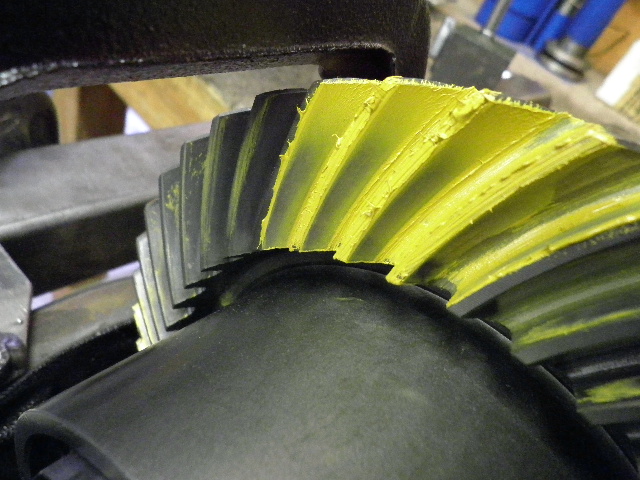

This is an optional step but I also took a paint of the pattern...drive side.

|

|

|

Coast.

|

|

|

First, the brace is removed.

|

|

|

I was able to remove the washer plate with just finger strength...an indication that it needs better CBPL than that.

|

|

|

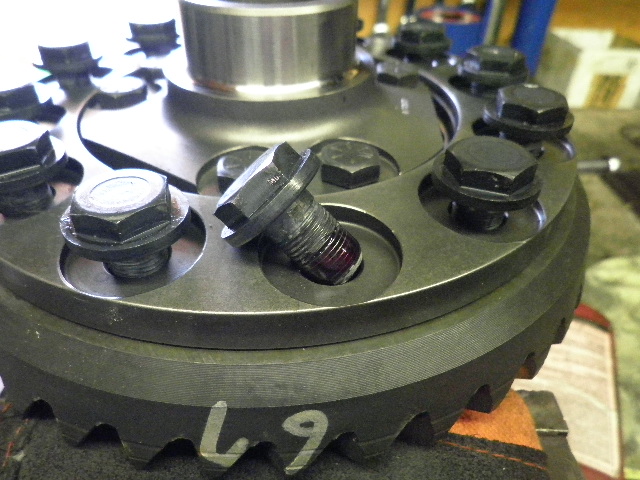

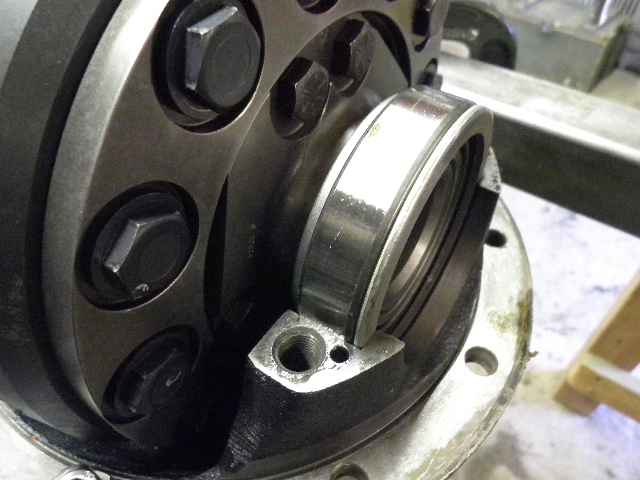

Here's the Truetrac and the 2 new bearings. I've always been impressed with the overall machining on these cases. Nice workmanship.

|

|

|

The paint on the pinion is where it should be.

|

|

|

I wanted to add perhaps 1 or 2 inch/pounds of preload. I placed it in this fixture and applied pressure with a 3 foot cheater bar.

|

|

|

I now had a minimal 2 inch/pounds of pre-load.

|

|

|

I re-staked it. As shown, it really didn't have to move very far at all. And, I might add, that it did take

a big effort to make that crush sleeve give that small amount of distance.

|

|

|

Used carrier bearing race on left with 76,000 miles....new one ready to go in on the right.

|

|

|

The factory uses a good loctite on the threads of the 12 flange bolts here. Make sure you have a socket that fits the head well...

strip the head of one of these bolts and that spells trouble.

|

|

|

The soft chisel easily drops the ring.

|

|

|

Surface check...all is good.

|

|

|

These bolts are perfectly re-usable. Red loctite on the threads...

|

|

|

...and 100 ft/lb on all 12.

|

|

|

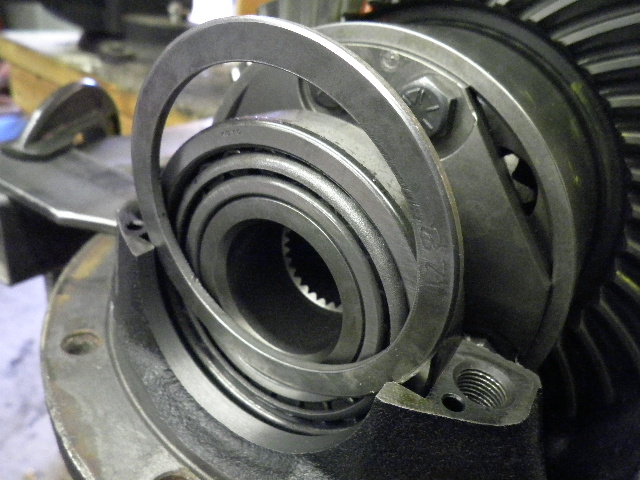

Both carrier bearings (90366-51001) are pressed on the Truetrac journals at the same time.

|

|

|

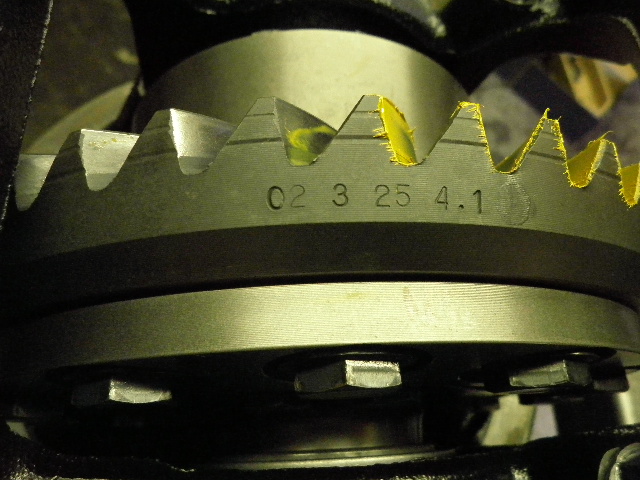

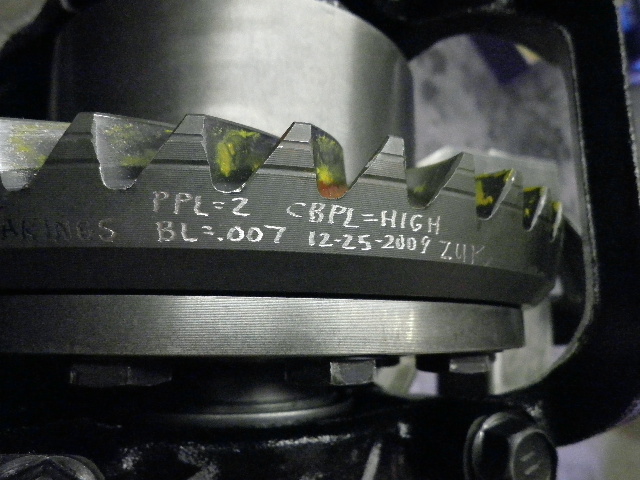

I was able to push the factory washer plates in by hand...the measured backlash (.007") was very close to what it needed to be

but the CBPL was almost zero. I'm sure there are people that have done there own TT swap and maybe had the same results I have here

and ran it that way. What's going to happen is the ring gear is prone to greater deflections under heavy loading especially. That

will result in the ends of the ring gear teeth breaking off with time.

|

|

|

That's why it's nice to have a full selection of plates.

|

|

|

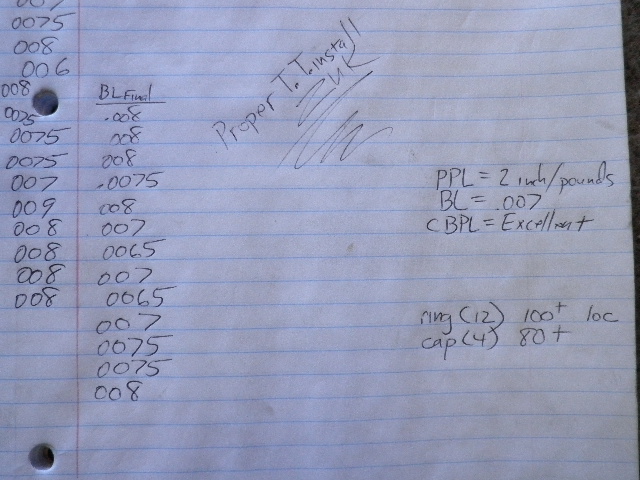

So, what I did here was substitute a plate in each side that was .005" thicker than the OEM one. This kept my backlash the

same but added in more bearing pre-load (.010" total more). I tapped the brace in place and tightened the 4 bolts down. As expected,

the BL was about the same...but the CBPL was not up to par with me by using 2 fingers and rocking the ring back and forth.

|

|

|

So, off comes the brace...remove these thick plates...

|

|

|

...and substitute in plates that are even thicker. The plates on both sides are now .004" thicker. Shown in the pic

was about as far as I could get it with just finger strength. The plate on this side is now .009" thicker than OEM and

so is the plate on the other side. See notes at the end of this link.

|

|

|

It was so tight that the hammer could only get it in this far.

|

|

|

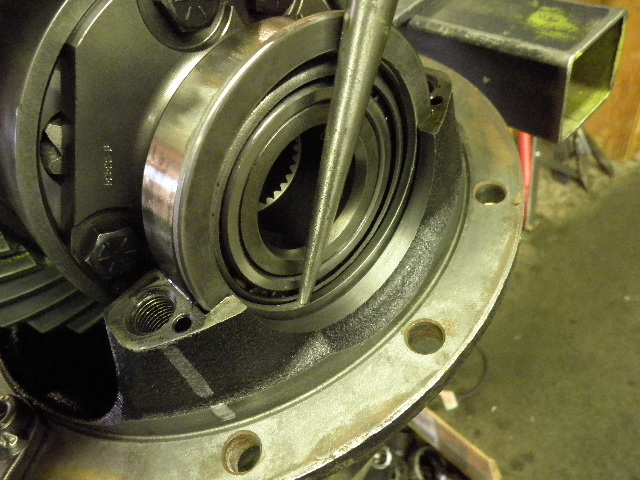

I like to use a taper punch to carefully tap it in the groove fully. When I have to do that, that means

I have the desired CBPL

|

|

|

```

|

|

|

Even the brace went on with some difficulty. I tapped a little on each side until it was flush all the way down.

|

|

|

I torque the 4 cap bolts to 80 ft/lb.

|

|

|

The bearings are now captured nice and tight...I even out the stresses between the 2 bearings by turning the pinion by hand while tapping on the caps

a few times. This is to make sure the Truetrac finds its 'center' and the BL measurement will be accurate.

|

|

|

I checked BL on about every 3rd tooth...it measured at the target .007". By the way, it's very difficult to measure BL when there

is so much CBPL and almost no PPL from the pinion end (the pinion is constantly trying to rotate).

|

|

|

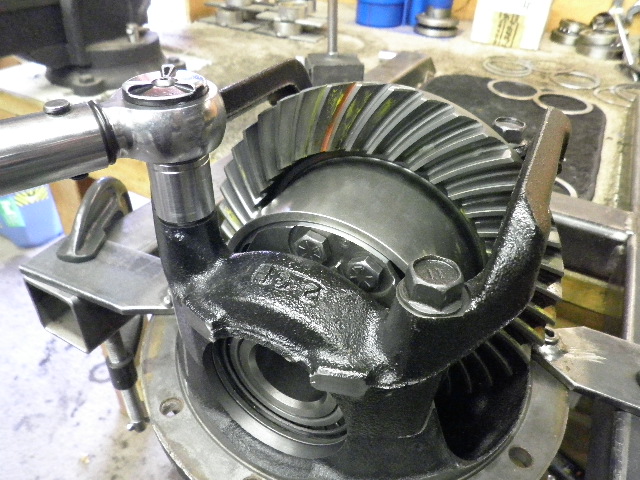

Final pattern check....the easiest way is to grab the pinion flange with a rag and apply light resistance.....use the 17mm wrench to move

the ring gear back and forth about 3 times. Done. The brace gets in the way somewhat but 3 teeth can still be painted this way.

|

|

|

Jeez...looks better than before :)

|

|

|

coast.

|

|

|

...

|

|

|

```

|

|

|

```

|

|

|

Notes of Max's install.

|

|

|

```

|

|

|

Ready for pick-up.

|

|