|

|

|

|

|

|

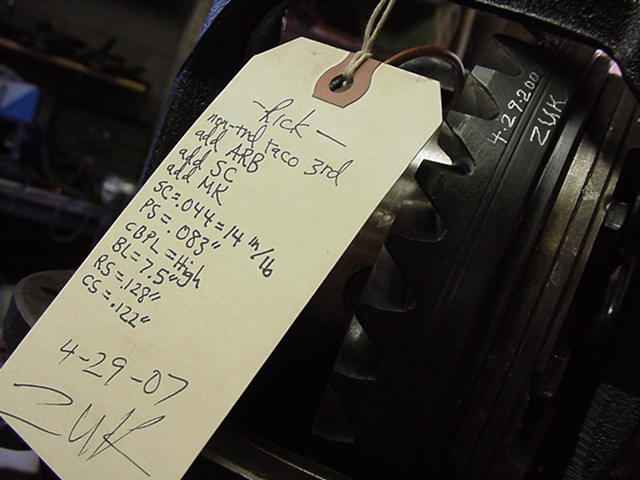

My cat, Bullseye, was checking out all the hardware that was going into this non-trd Tacoma 3rd sometimes called T100 3rd sometimes called 8.4" 3rd. To the left, a relatively new product, Taco solid collar, from ringpinion.biz adds to the overall durability and strength of this Taco 3rd gear install. |

|

Rick sent this used ARB locker back to ARB for a rebuild. They then forwarded it directly to me. |

|

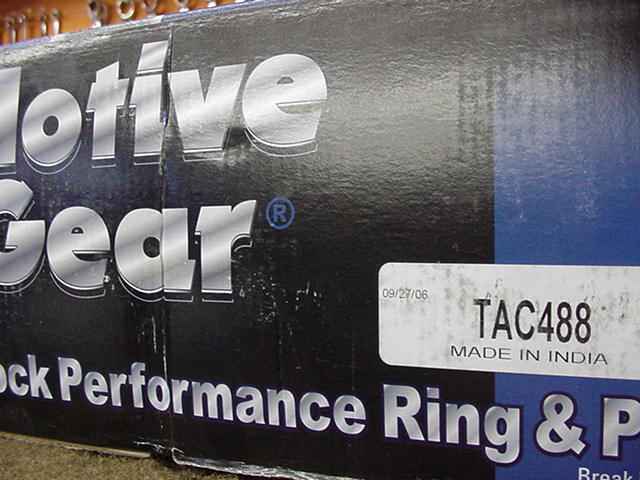

Motive gears are made in India and Italy. What I like about Motive is the high quality and the fact that every Motive box contains a Motive gear.....they don't substitute something else in the box like others. |

|

I like it when the master kit has Toyota OEM bearings. I think this is the first one I've seen with OEM. This kit came from

ringpinion.biz. As far as I know, Jeremy at ringpinion.biz is one of

the few to address the problem of the 'wrong carrier bearings' being supplied in the early model front IFS 7.5" master

kits(86~95). I recommend getting master install kits from these guys. |

|

The 3rd is stripped down and new races are pressed in. The pinion depth shim is not located behind the pinion head... it's located behind the inner pinion race as shown here. Here, the factory .083" shim is cleaned up and re-installed behind the race. Dana 44's and 60's are similar in this respect. By the way, the Taco inner bearing is about twice as beefy as the Dana 60. |

|

The 488 pinion is pressed on the monster Taco bearing (also bigger than the massive V6 bearing). My 10 ton press has served me well for about 10 years now. |

|

I started with .052" for the solid collar shim...way loose. Then .048 then .045 then .044" was perfect with 14 in/lb of pinion drag. |

|

14 in/lb of rolling pinion pre-load as measured by this very affordable torque wrench ($37) from Park Tool TW-1. |

|

The ring's mounting surface was filed and the flange style bolts were coated with red Loctite....95 ft/lbs on all 12 of them. |

|

I still have to drill and tap the hole for the copper tubing. |

|

With the stabilizing girdle in place, I was able to paint a pattern. Drive side with .083". Excellent. |

|

Coast side .083"....nice. |

|

The factory had .118 on the left and .115" on the right. It's important to have a selection of shims to set the BL and the Carrier Bearing Pre-Load(CBPL). These shims can run about $7 each. |

|

The shims require some extensive coaxing with a hammer to get the CBPL tight....using the aluminum based anti-seize on the related surfaces helps install them. |

|

....... |

|

To get the BL at 7.5 thou and the CBPL extra tight, the final shims ended up as .128" on the left and .122" on the right. |

|

The girdle bolts are torqued to 90 ft/lb. |

|

BL was a nice .0075"...very repeatable from tooth to tooth also. |

|

Some basic tools are used to drill/tap the hole for the brass fitting. |

|

... |

|

... |

|

I applied a small amount of Liquid Teflon to the brass threads and then assembled it. |

|

The tiny fat o-ring is liberally coated with gear oil and inserted on the copper tube. |

|

No spec is mentioned in the ARB paperwork about the torque spec for the intermediate brass coupler. I found that about 40 in/lb "felt good". I imagine some air leaks are caused by over-tightening of the fitting resulting in the shredding of the o-ring and then the air leak. |

|

The finished Taco 3rd will be returned in the same package that Rick sent it to me in. These "ACTION PACKERS" are the ticket! They cost about 20 bucks each but they make it easy to package the 3rds. There's a PACKER that's even one size smaller than this one and is perfect for the 3rds. |

|

8.4" 3rd ready for the return trip. ZUK |

|