| Rex's 2017 Tacoma had an annoying leak from the front clamshell area after a 529/elocker install |

|---|

| (60 BIG pics loading) |

|---|

| May 5 2022 |

|---|

|

That's the basic jist of it....another shop installed 529 gears and an elocker in the front 8" clam and Rex noticed a small gear oil puddle

every couple of days. The clam was removed and brought to my humble shop.

The tube extension and clam support arms were removed first. |

|---|

|

|

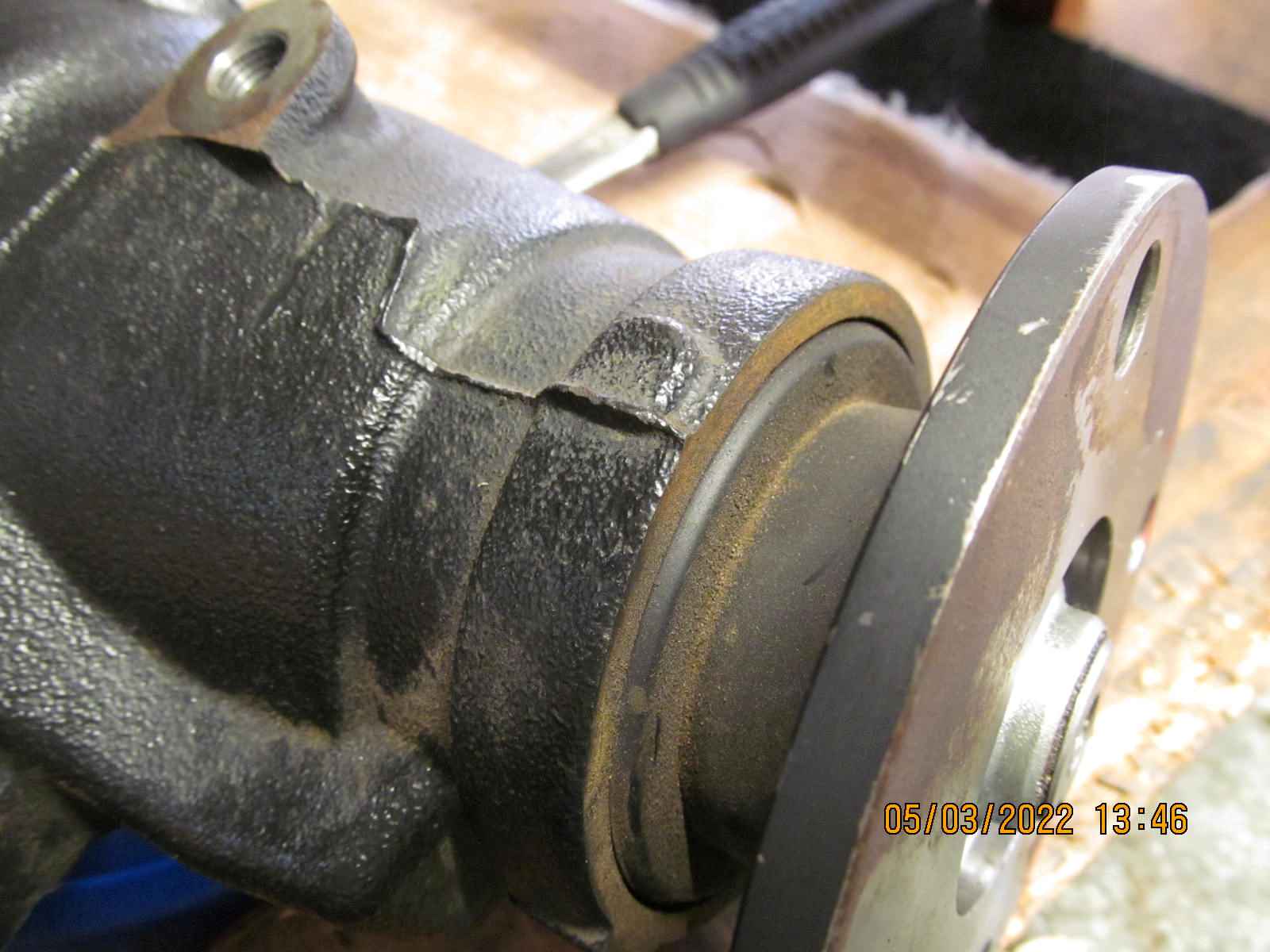

| The outer seal on the passenger-side tube extension flange was suspect but hard to say for sure. |

|---|

|

|

| There was gear oil spilling out but kind of expected it here. It will see a new factory seal. |

|---|

|

|

| The driver-side seal for the stub axle looks ok....a new factory seal will replace it. |

|---|

|

|

| The pinion seal does look perfect....don't think it was coming from here. |

|---|

|

|

| No sign of any oil. |

|---|

|

|

| This shows the bottom of the clam and the generic black silicon RTV makes me wonder if this is the leak. |

|---|

|

|

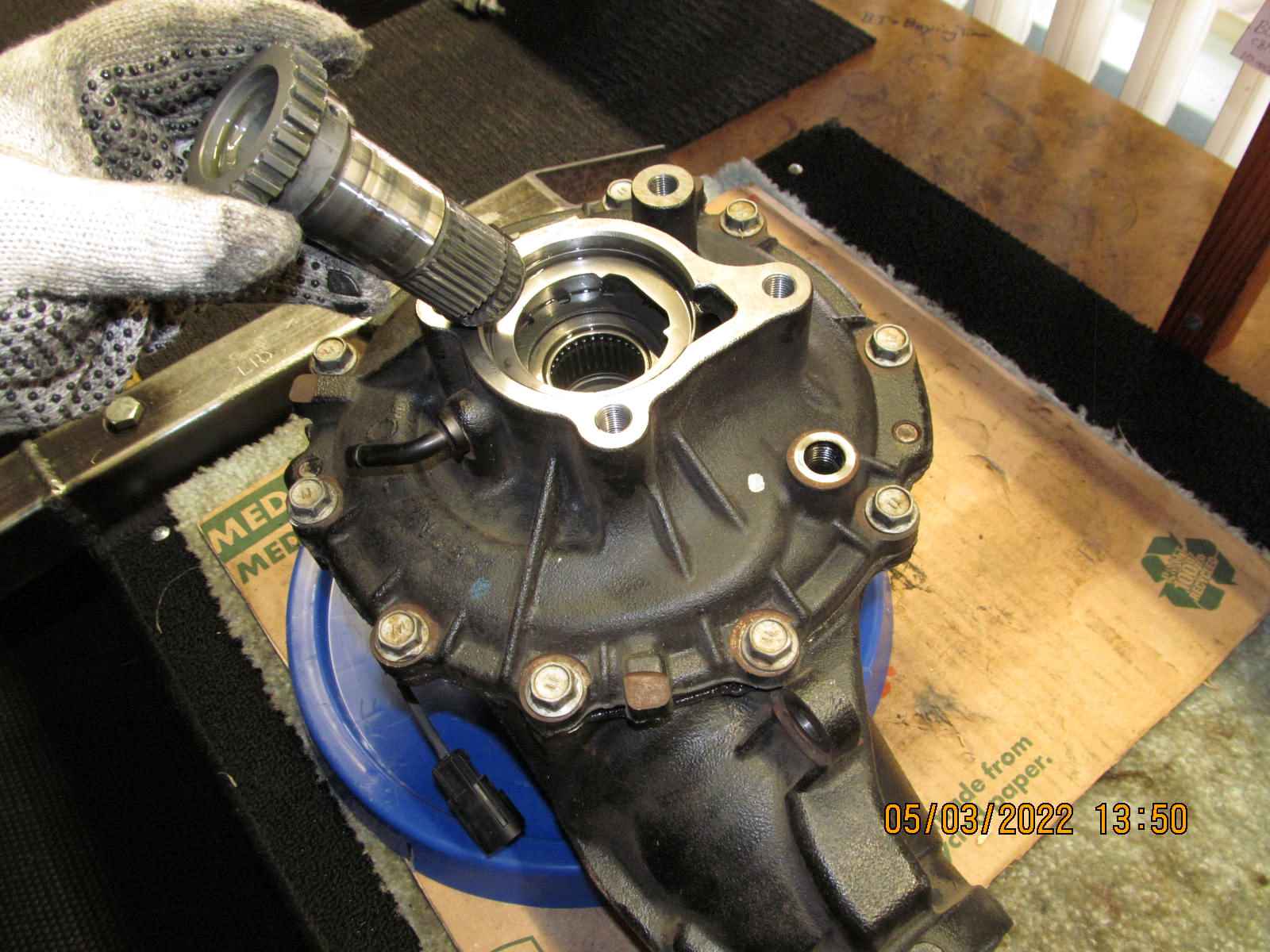

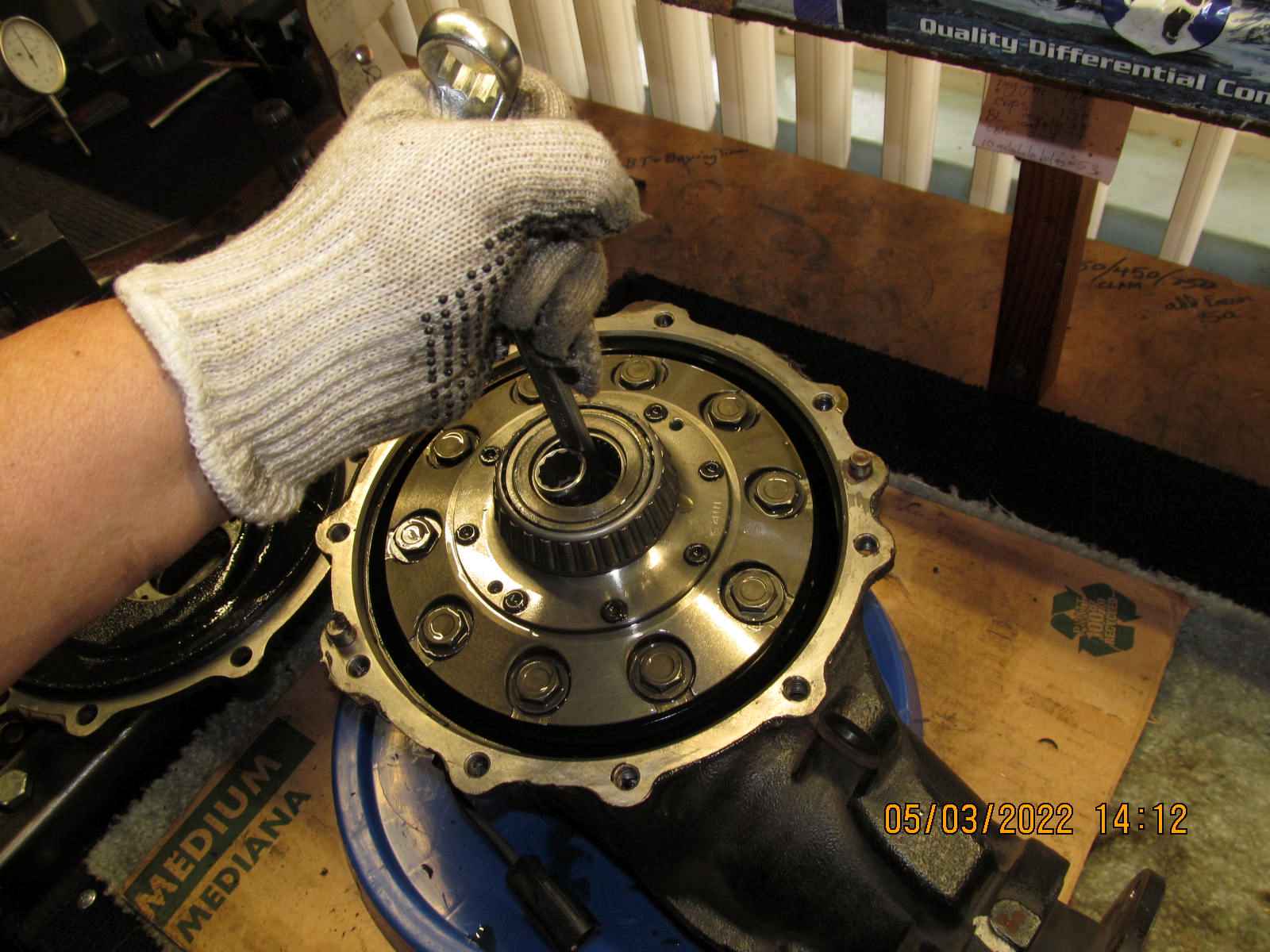

| Let's take out the inter-shaft... |

|---|

|

|

| 2 heavy duty screwdrivers and a tap-tap in the middle will allow the axle clip to pop out. |

|---|

|

|

| Easy peasy. |

|---|

|

|

| A sloppy Ding mark.... |

|---|

|

|

| .............. |

|---|

|

|

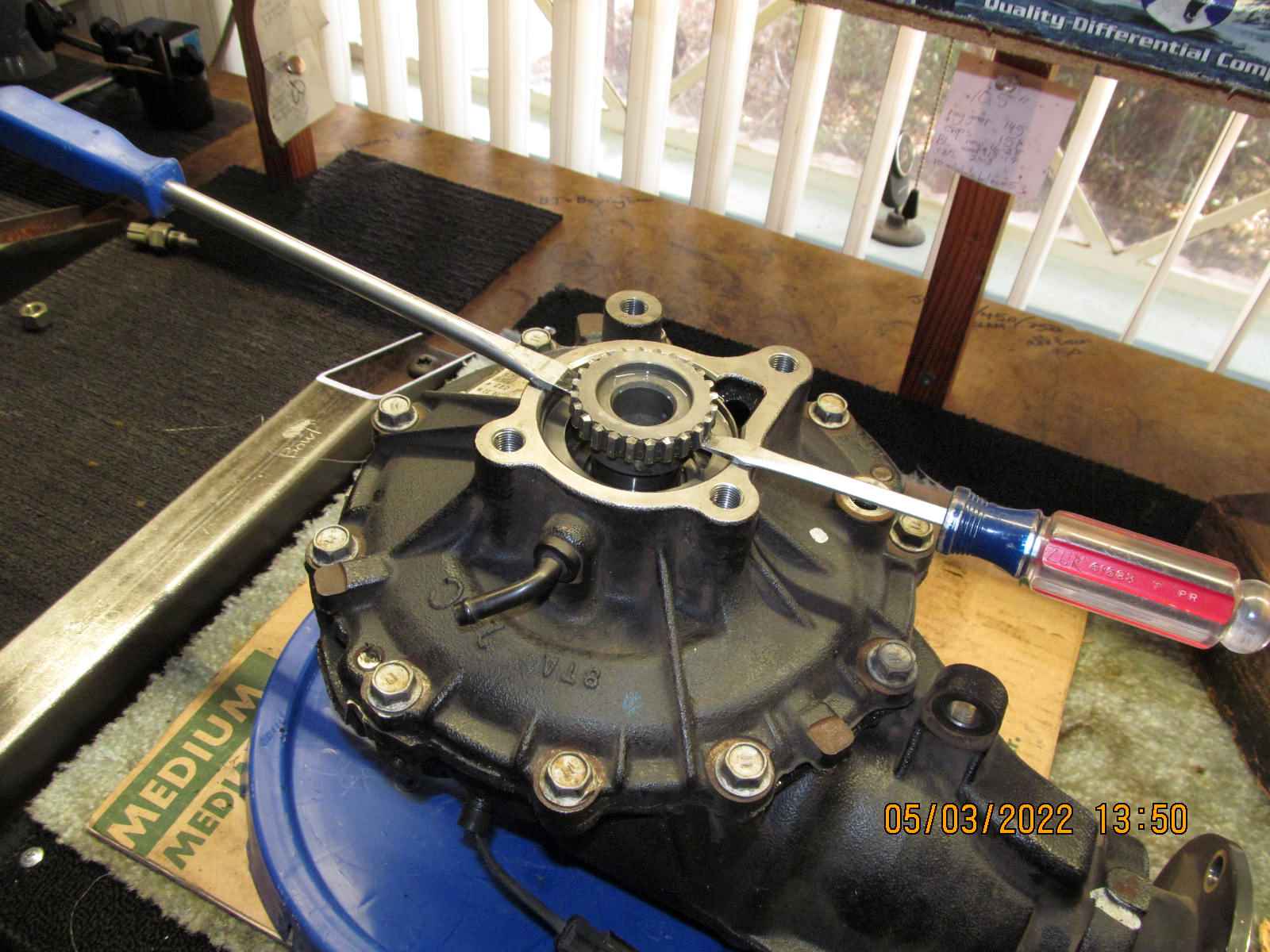

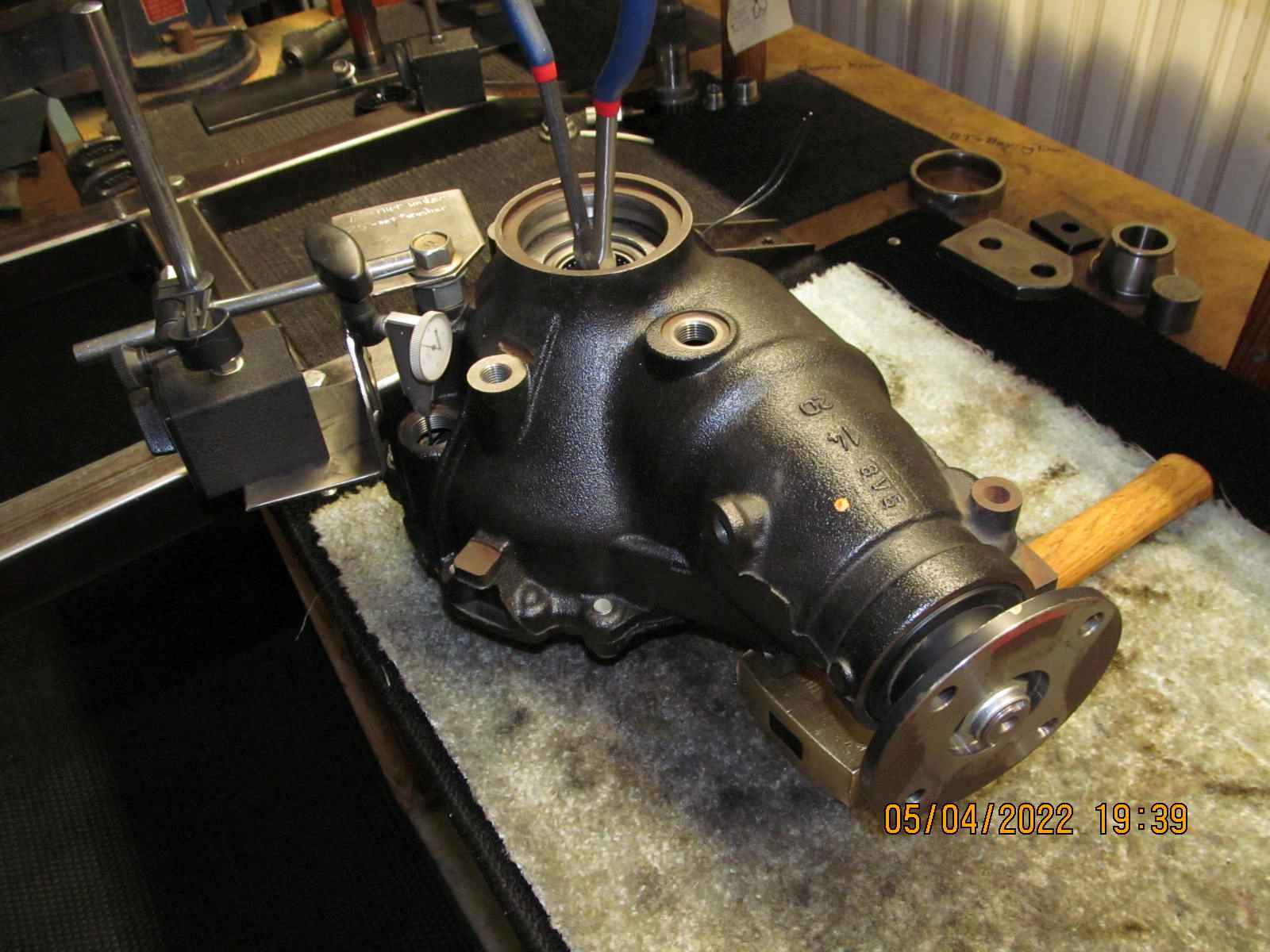

| A quick check of total bearing preload and it is very high...about 40 inch/pounds. |

|---|

|

|

| This clam made on August 30, 2017. |

|---|

|

|

| Seems like every clam I get with the elocker in it has no steel bushing welded over the hole for rubber grommet support. |

|---|

|

|

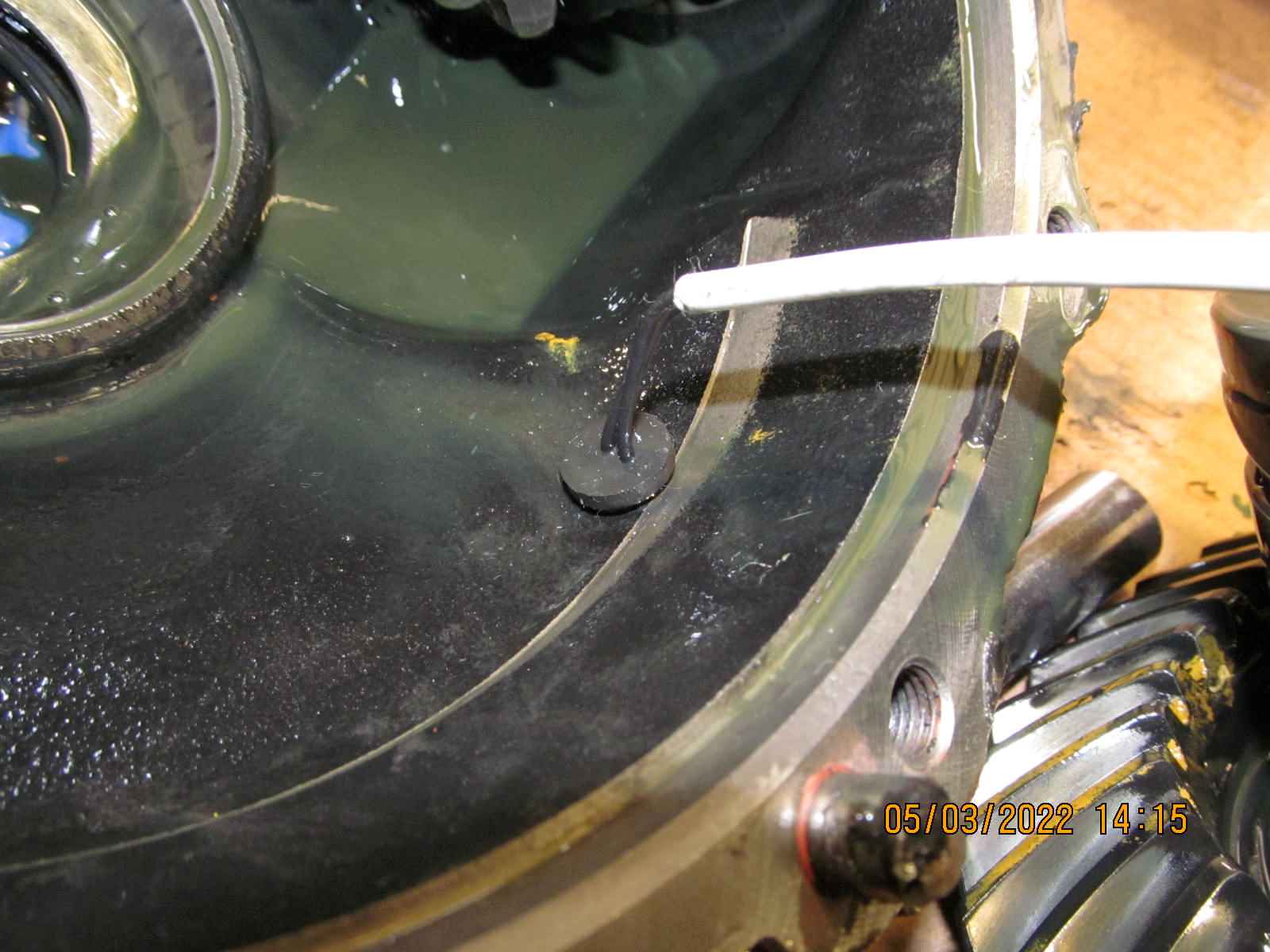

| This is the spot where I think the oil was seeping out... |

|---|

|

|

Ohh ya....it's been mentioned before but there are 2 issues going on here.

1---the hole was "over-drilled" with a .500" drill bit....should have been .463"

2---No steel sleeve has been MIG/TIG welded on for sealing support.

To me, it looks like gear oil was seeping out here. |

|---|

|

|

This is the spot where I will drill the .463" hole...left side of the rib is the Cow Pasture. 3" up and about 1 1/8" left of the rib.

Right side of the rib is the Valley. That hole is drilled way too high up the valley. Too close to the crown teeth. |

|---|

|

|

| The cow patty marks the desired spot :) |

|---|

|

|

This is my humble "steel sleeve" that I have welded on many clams that get the elocker.

It's just a lug nut and when the .463" drill bit passes thru it, almost all traces of the threads disappear. |

|---|

|

|

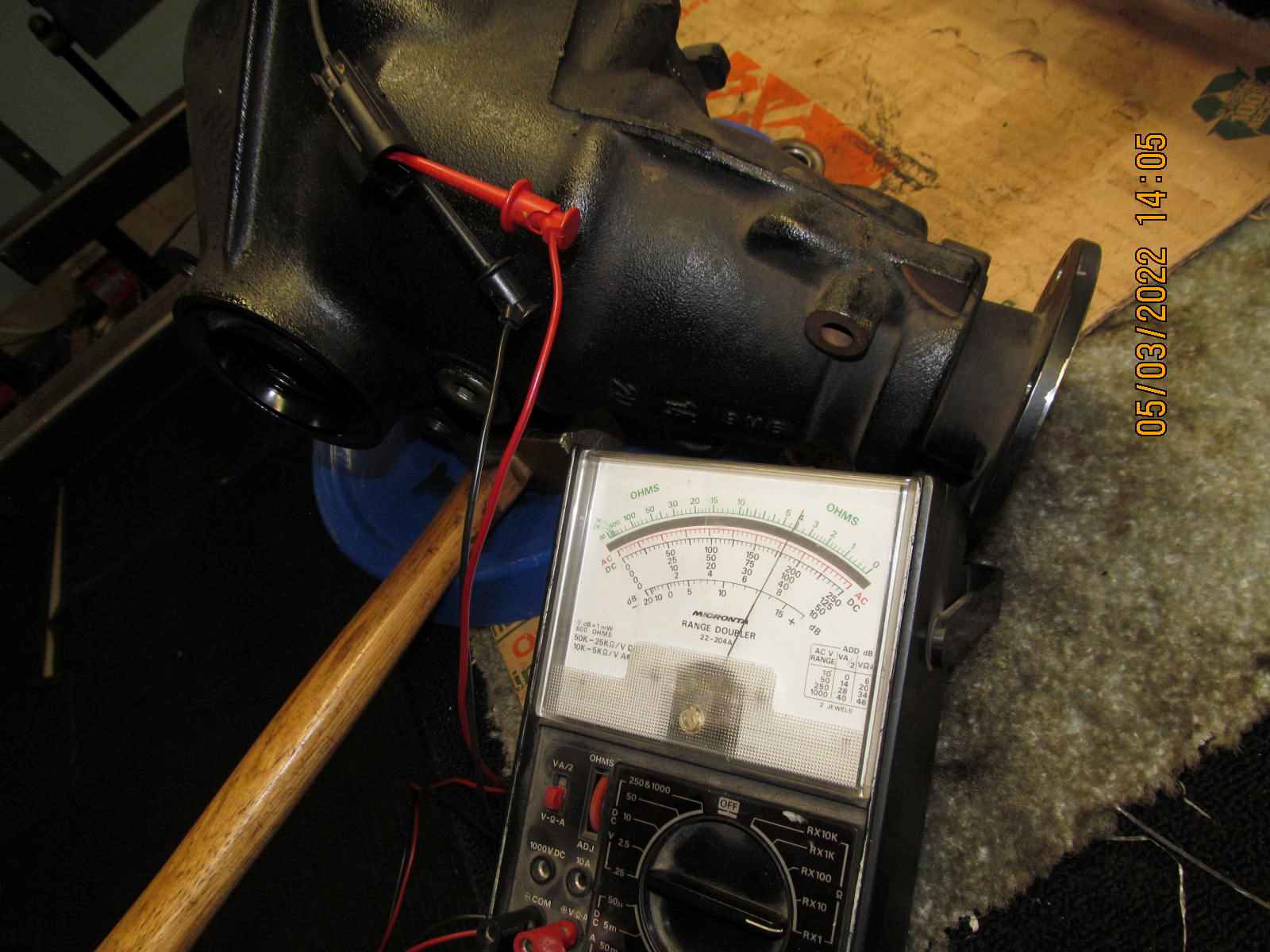

| A quick check with the ohm meter shows about 4 ohms across the magnetic coil which is good. |

|---|

|

|

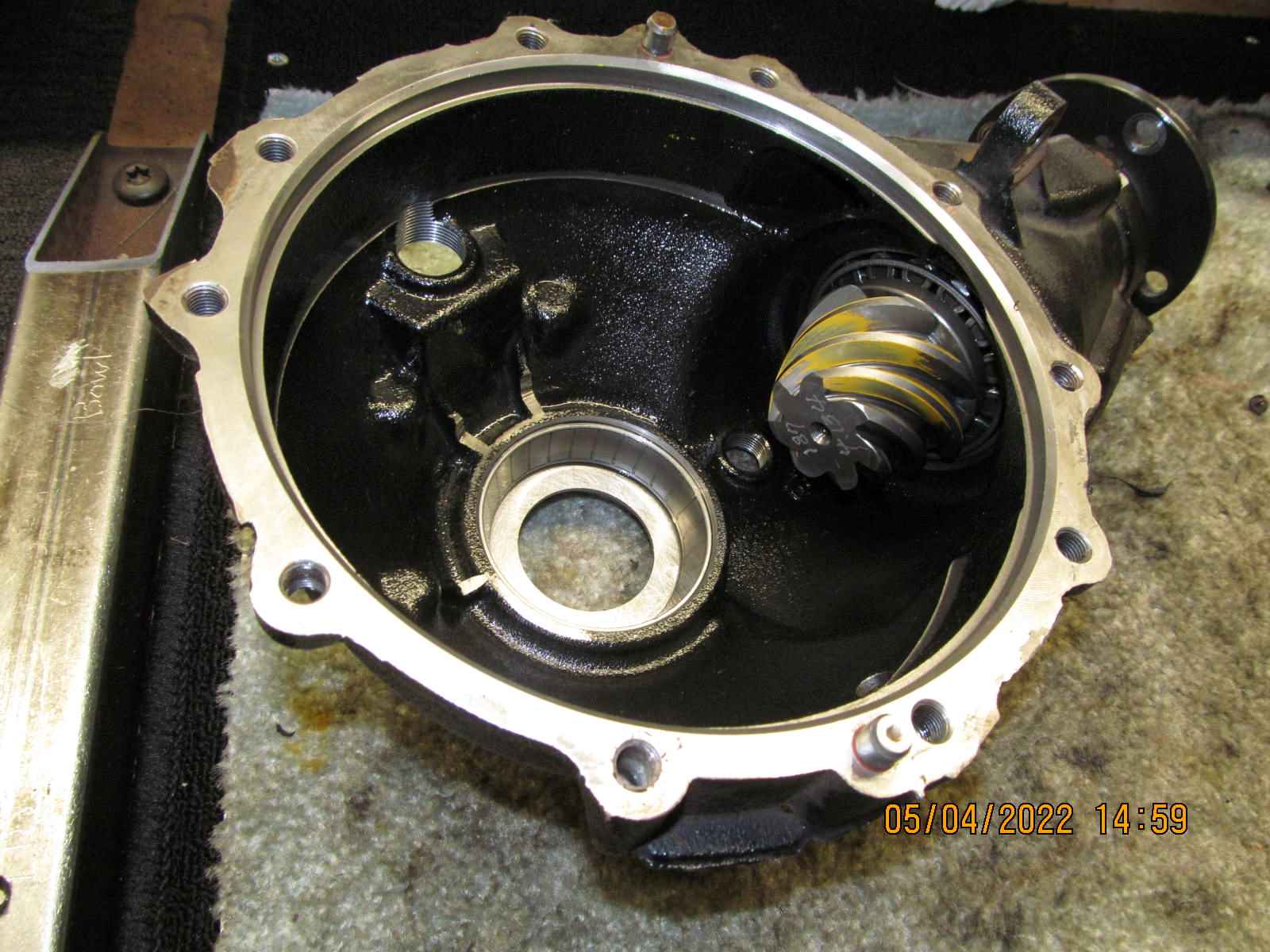

| Back to the teardown.....the lid has been removed. |

|---|

|

|

| Another simple tool for the clams.... |

|---|

|

|

| Now the heavy center carrier can be easily pick up and moved out of the way. |

|---|

|

|

| That grommet is drilled very close to where the ring gear teeth are. |

|---|

|

|

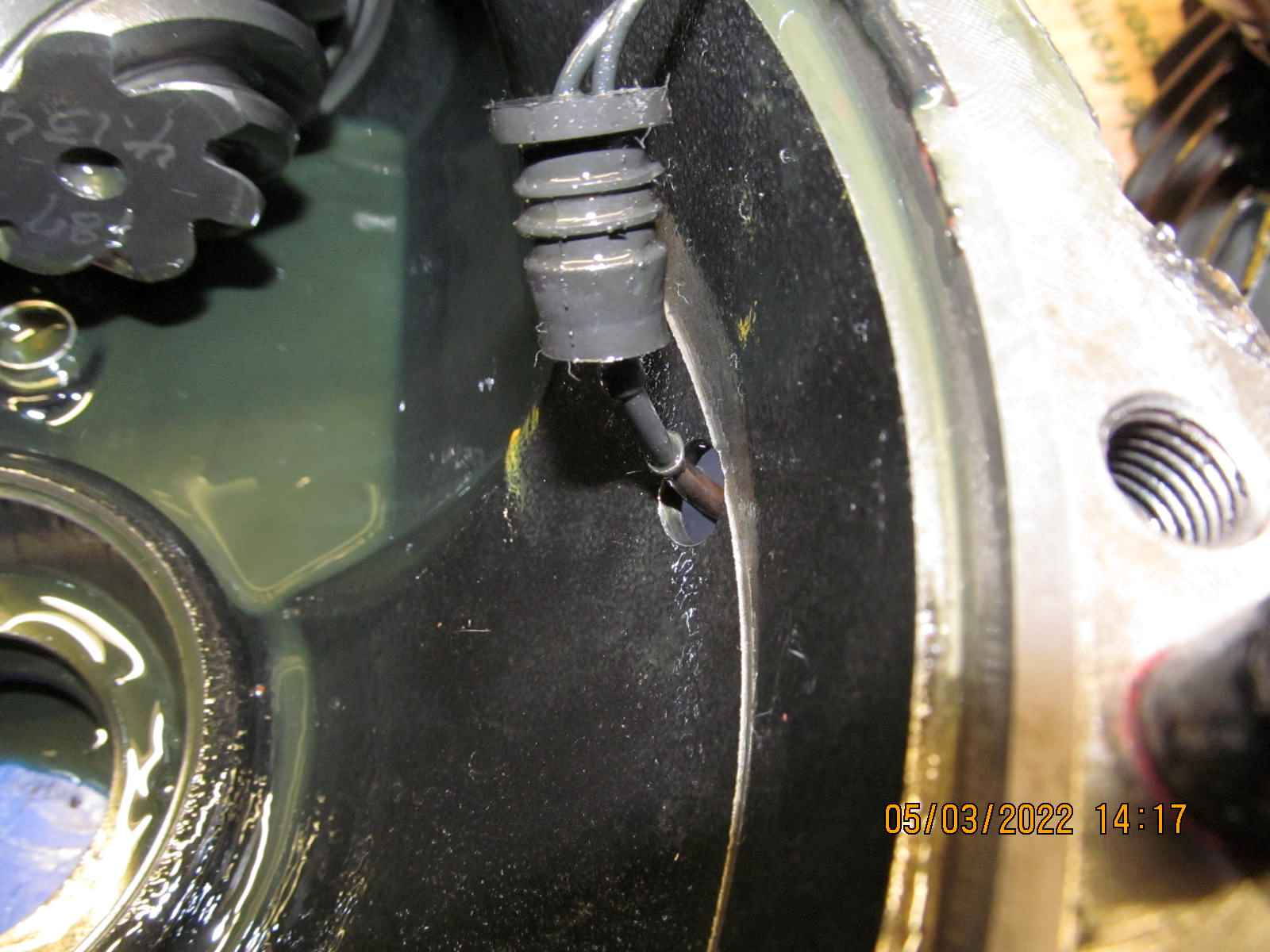

The rubber grommet basically came out with no resistance at all......it fell out.

As can be seen, the wall thickness of the drilled hole is maybe 1/8"...

and the rubber grommet was really not sealing in the gear oil very well. |

|---|

|

|

| Draining out as much of the oil as possible.... |

|---|

|

|

A check of pinion preload shows maybe 13 inch/pounds which is a good solid number.

This means the carrier bearing preload is excessive with about 30 inch/pounds.

That will change shortly. |

|---|

|

|

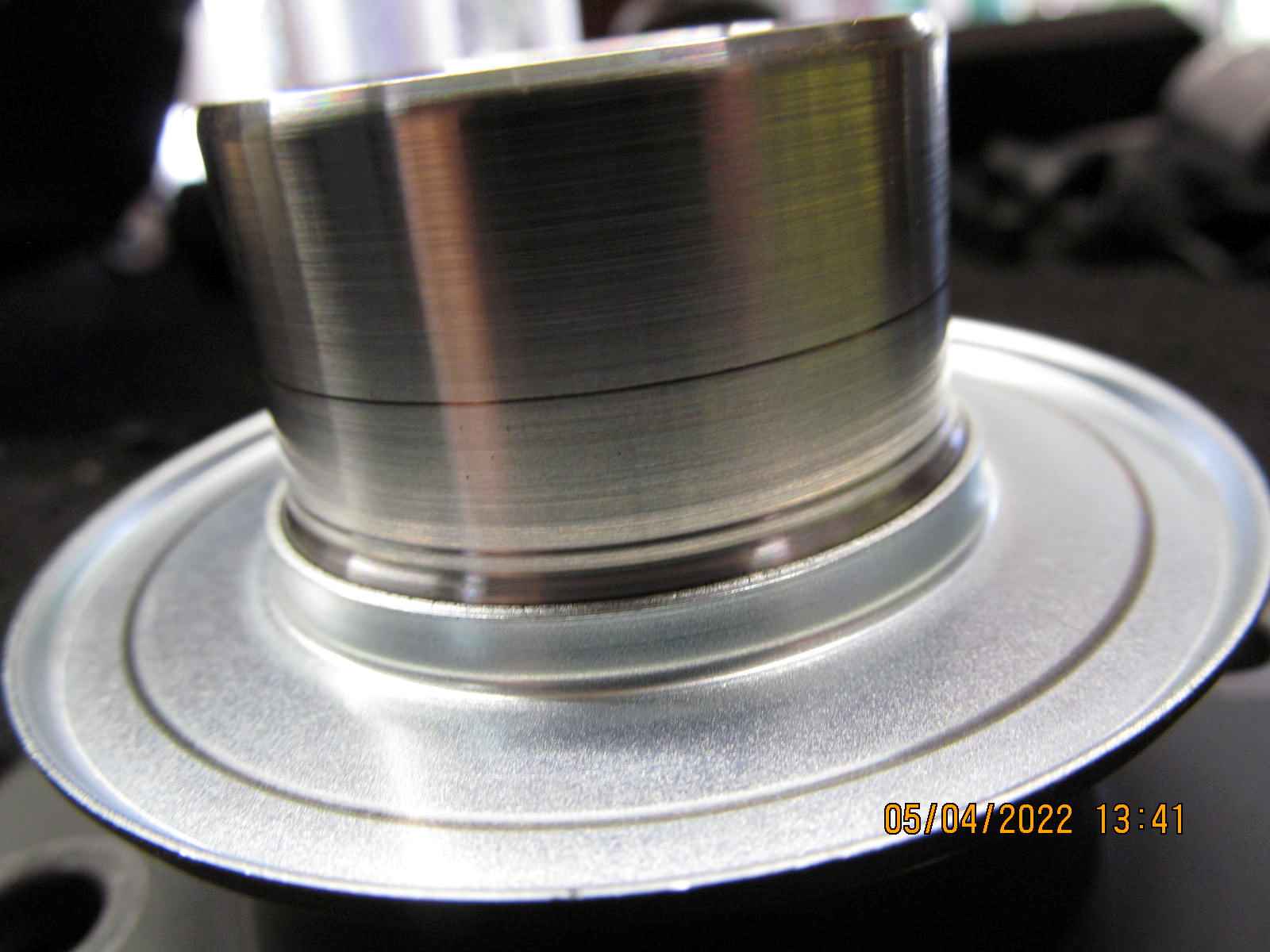

| I don't think the shop changed out the factory seal....still the genuine part number and recessed the usual .120" |

|---|

|

|

| The pinion flange looked almost brand new. |

|---|

|

|

| The factory NOK driverside seal is coming out... |

|---|

|

|

| Almost no damage :) |

|---|

|

|

Kudos to the shop for clearancing the 3 ribs properly.

This shown washer plate (.074") in the bowl was back to back with a .010" shim.

That shim resulted in excessive carrier bearing preload.

A washer plate (.078") was located from my collection that was only .004" thicker

and gave the proper CBPL with the right backlash. |

|---|

|

|

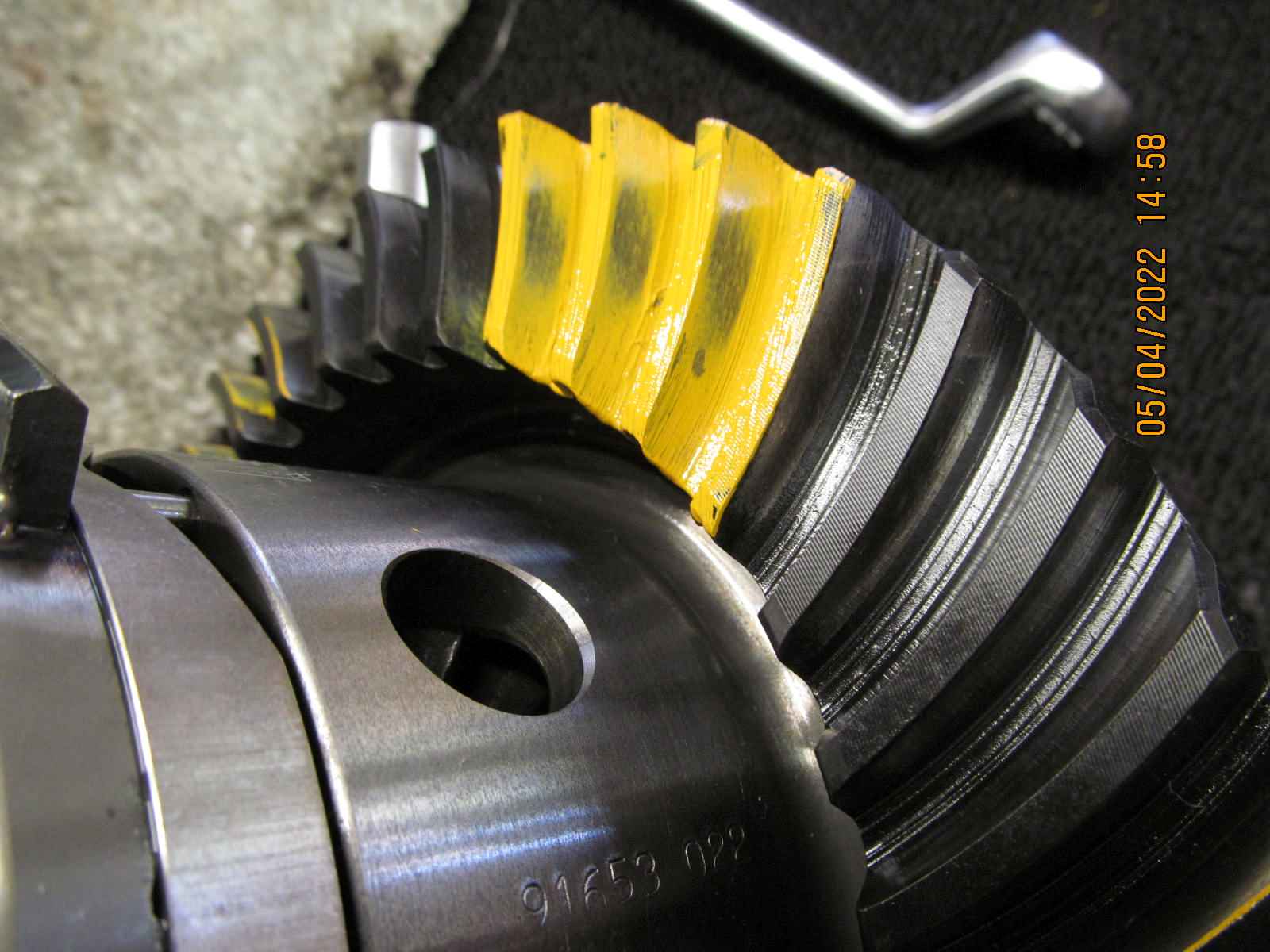

| Paint was applied to a few teeth and re-assemble it. |

|---|

|

|

| Backlash and bearing preload were spot on. |

|---|

|

|

| A tool that allows for doing good, easy to read paint checks. |

|---|

|

|

| ......................... |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| Apply a small resistance to the pinion flange and turn the ring gear via the upper side gear. |

|---|

|

|

Drive side....beautiful....the shop nailed it right on.

As shown in the pic above, this is the pattern for the quietest running gears.

It's not the left/right position that is the most important....

It's the up/down that is the most important parameter. |

|---|

|

|

| Coast is ok. |

|---|

|

|

| The pattern on the pinion teeth look great. |

|---|

|

|

| '''''''''''''''''''''''' |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| ////////////////////// |

|---|

|

|

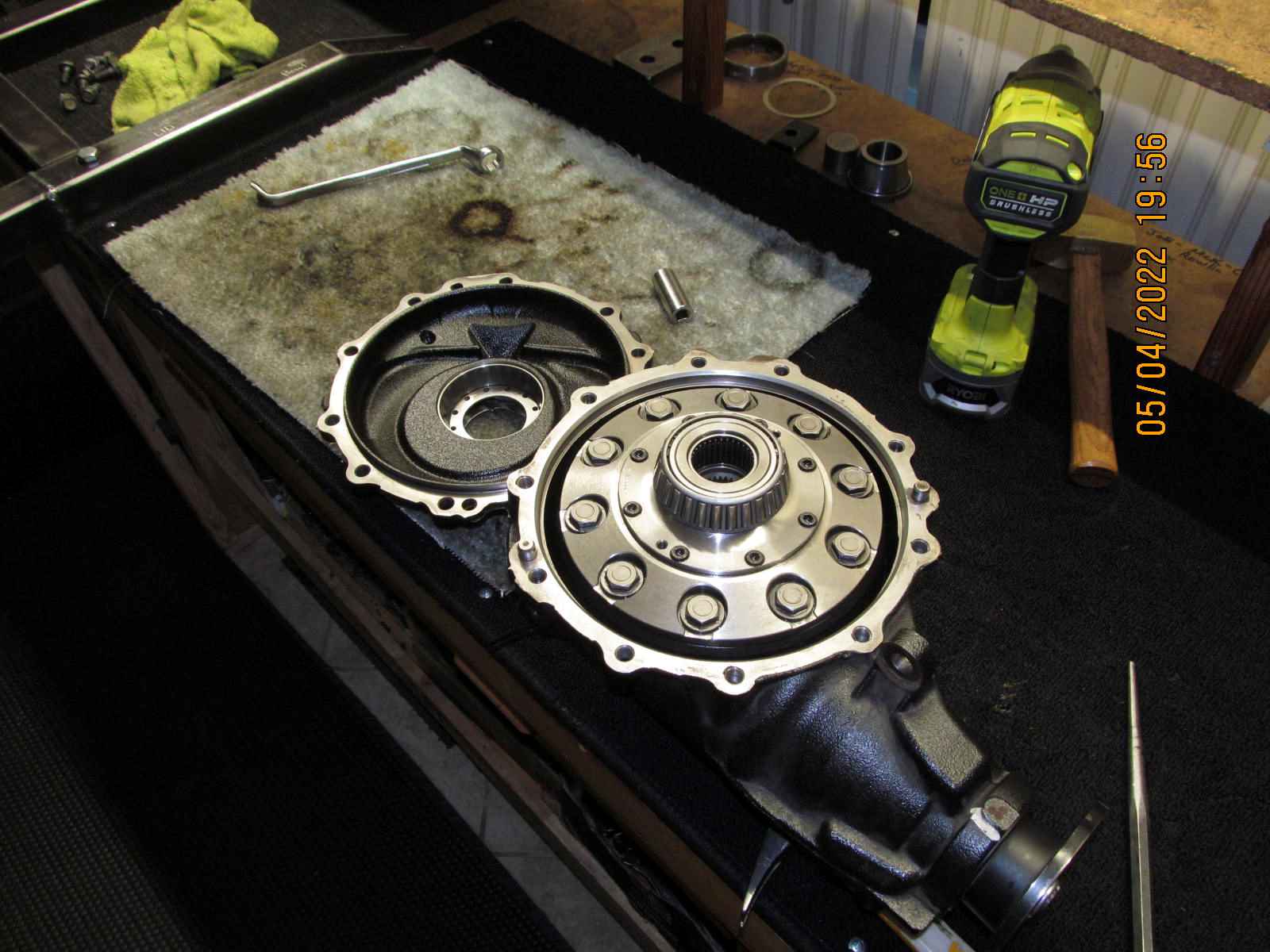

| This is showing the part where the washer plate was pressed out...... |

|---|

|

|

| ....and the new washer plate that is only .004" thicker. |

|---|

|

|

| The filled in hole and the hole in the cow pasture with the 'sleeve' MIG welded on. |

|---|

|

|

| Last checks on backlash and all is good. |

|---|

|

|

| Lid is removed and cleaned of oils. |

|---|

|

|

| The factory orange FIPG is applied. |

|---|

|

|

| ....and the 10 bolts are final torqued to 37 ft/lb. |

|---|

|

|

| Generally best to stay away from the generic seals that are supplied in the after-market kits. Factory is best. |

|---|

|

|

| Done |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| '''''''''''''''''''''''''' |

|---|

|

|

| ............................ |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

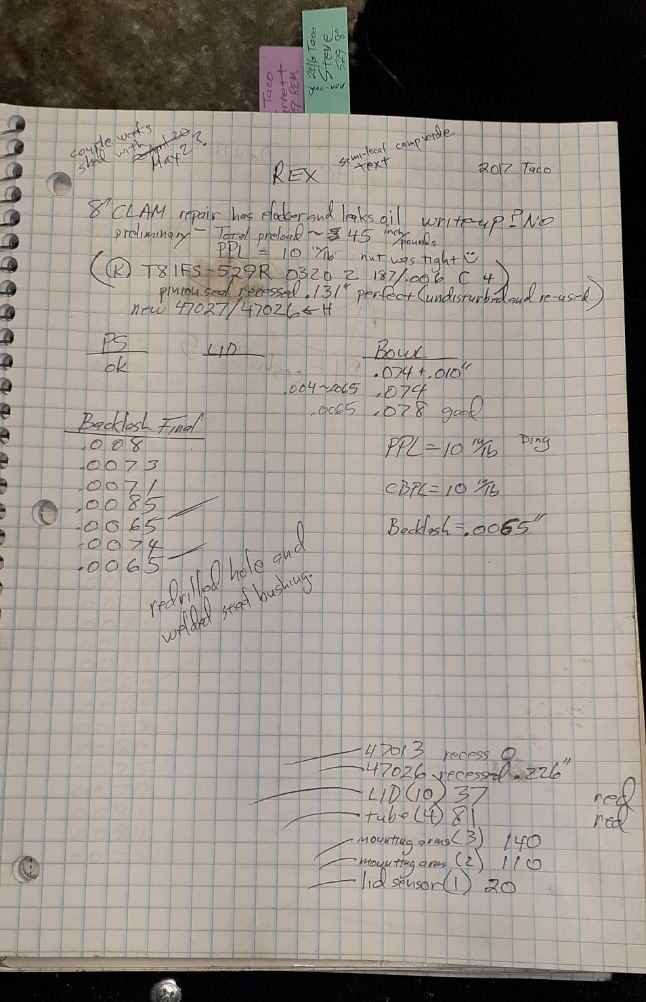

| A snapshot of the notes. |

|---|

|

|

|