|

Tim is local to me and has a 2001 4x4 Runner with 255/85/16(33x10.5) Cooper ST's. 488 gears were installed at a

valley 4x4 shop and the rear gears immediately whined.....a constant whine that increased in frequency as the speed increased.

It was taken back and a solid collar was installed

and it whined just as loud. Tim then brought the 3rd over to me and I dis-assembled it while he watched.

Before tearing it down, a pattern check was taken. The above pic is the drive side and the pattern is far out of spec.

|

|

|

Coast side pattern way off. Note that these are quality Precision gears.

|

|

|

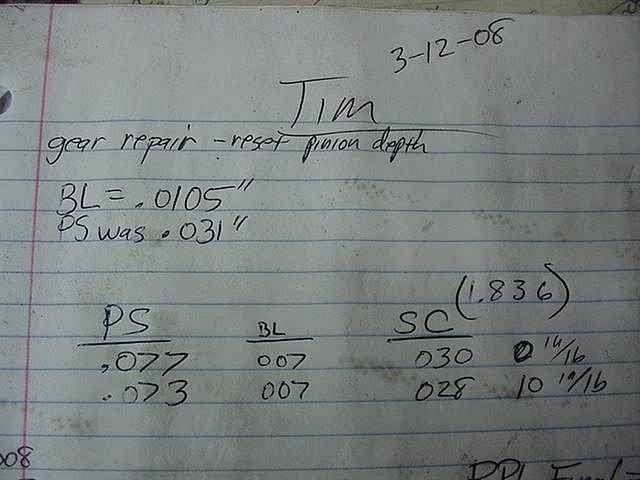

Upon further teardown, we discovered that the pinion only had .031" worth of shims....075 is more typical of what

it should have.

|

|

|

The focus isn't perfect but this is inside the carrier on the surface that the big pinion race seats against. The little

chinger marks are the result of using a chisel and hammer to tap out the race. These marks were not filed down smooth...

this means the race cannot fully seat flat.

|

|

|

The chinger marks were filed down flat and the race is pressed back in.

|

|

|

I chose to try a .077" pinion shim and the bearing is then pressed on.

|

|

|

The pinion assembly is then installed without the solid collar. The solid collar will be installed last after the

correct pinion shim is determined.

|

|

|

The nut is tightened carefully until about 10~15 inch/pounds of pinion pre-load (PPL) is measured.

|

|

|

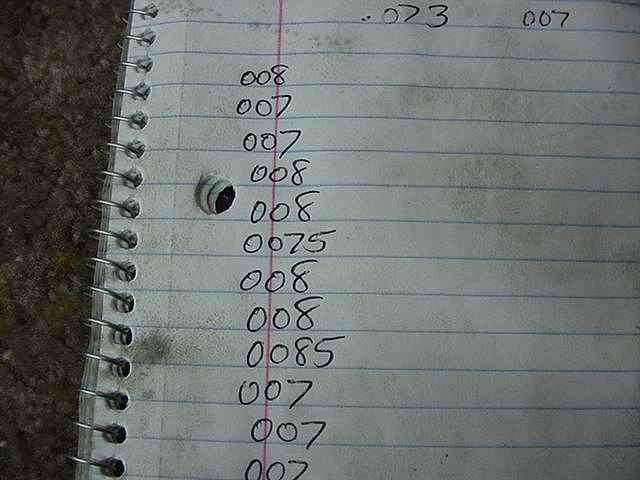

The carrier is then secured to the fixture...the case is installed...backlash is set around 007 and it's ready for

a pattern check.

|

|

|

This is much better but perhaps just a tad deep here.

|

|

|

Coast is suggesting it's a little deep also. Now to remove the pinion and re-shim to .073"

|

|

|

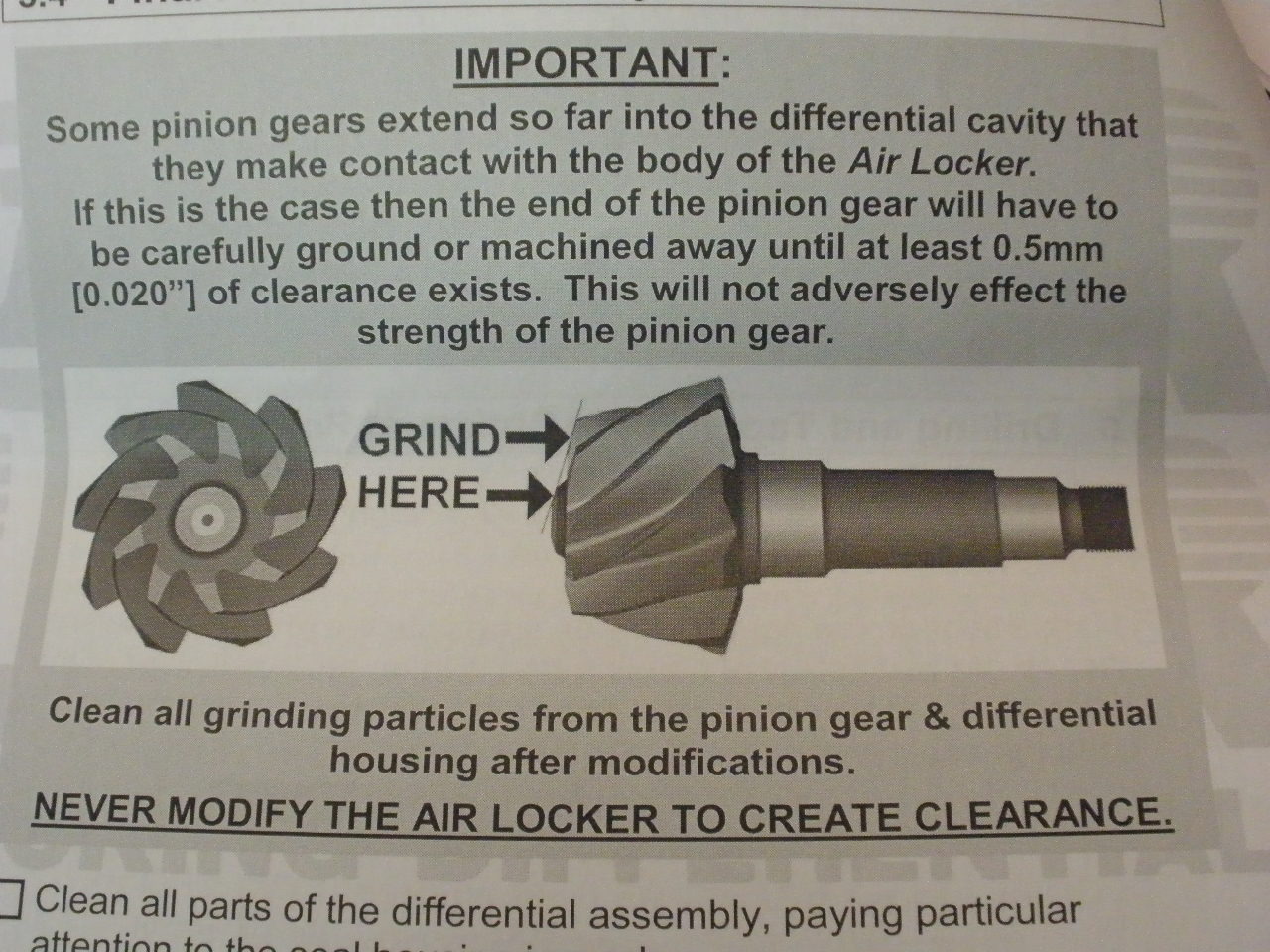

While the pinion is out, it's now a good time to use the flapper wheel to remove the

tips of the teeth. See the next picture below. The ARB cases are a little larger in

diameter than the OEM cases and others so it's almost common for the pinion teeth to make

contact with the case. The flapper wheel does not cause enough heat to worry about.

|

|

|

|

|

...press off the bearing...replace shim with 073...re-install pinion assembly...re-install case and set backlash to 007 again...

|

|

|

Very nice.

|

|

|

...

|

|

|

With the pinion depth established, the pinion is now pushed out to install the solid collar. Re-using the

same collar and same collar shims should have resulted in the same 10 inch/pounds of PPL that it originally had.

Instead, I measured only about 1 or 2 inch/pounds. This is because I earlier had filed off the chinger marks and

now the race sets in deeper. I subtracted 2 thou off of the solid collar shim pack and had 10 in/lb of pre-load again.

|

|

|

A new seal is installed and a good used nut is coated with red Loctite.

|

|

|

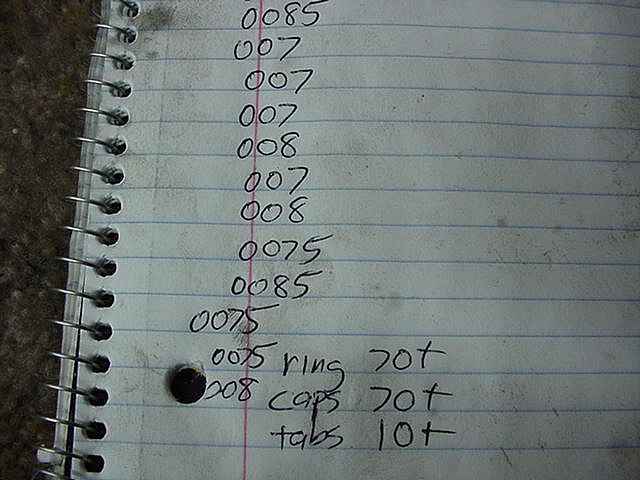

Before installing the case for the final time, the ring bolts were verified to be tight (70+ ft/lb) and they all were.

|

|

|

With the .0075 backlash set and carrier bearing pre-load (CBPL) tight, it's now time to re-route

the soft copper air-line as neat as possible.

|

|

|

With that done, the last check is the leak test.

|

|

|

I have a test hose the has a shut-off valve that let's me to engage the ARB and trap that 80~90 psi of air....

|

|

|

...then I monitor, for about 10 minutes, the pressure gage for leaks. None found here on Tim's set-up. :)

|

|

|

...

|

|

|

The copper routing turned out pretty good. The jpeg picture is deceptive...the routing is much more uniform than it appears.

|

|

|

.......................................................

|

|

|

..........................................................

|

|

|

There's about 20 backlash measurements because I check BL on every other tooth when done.

Although this Precision ring and pinion varied very little at less than .002", I have seen many others

vary 4 ~ 8 thousandths around the ring gear. This can happen even on known good gears and

that's why it's important to check BL on the full circumference.

|

|

|

This gear repair will be very quiet and strong for years to come.

|

|