|

Tanner's Hi-Pinion Front gets Nitro 488 and ARB RD132

|

|

(57 BIG pics loading)

|

|

JULY 7 2016

|

|

|

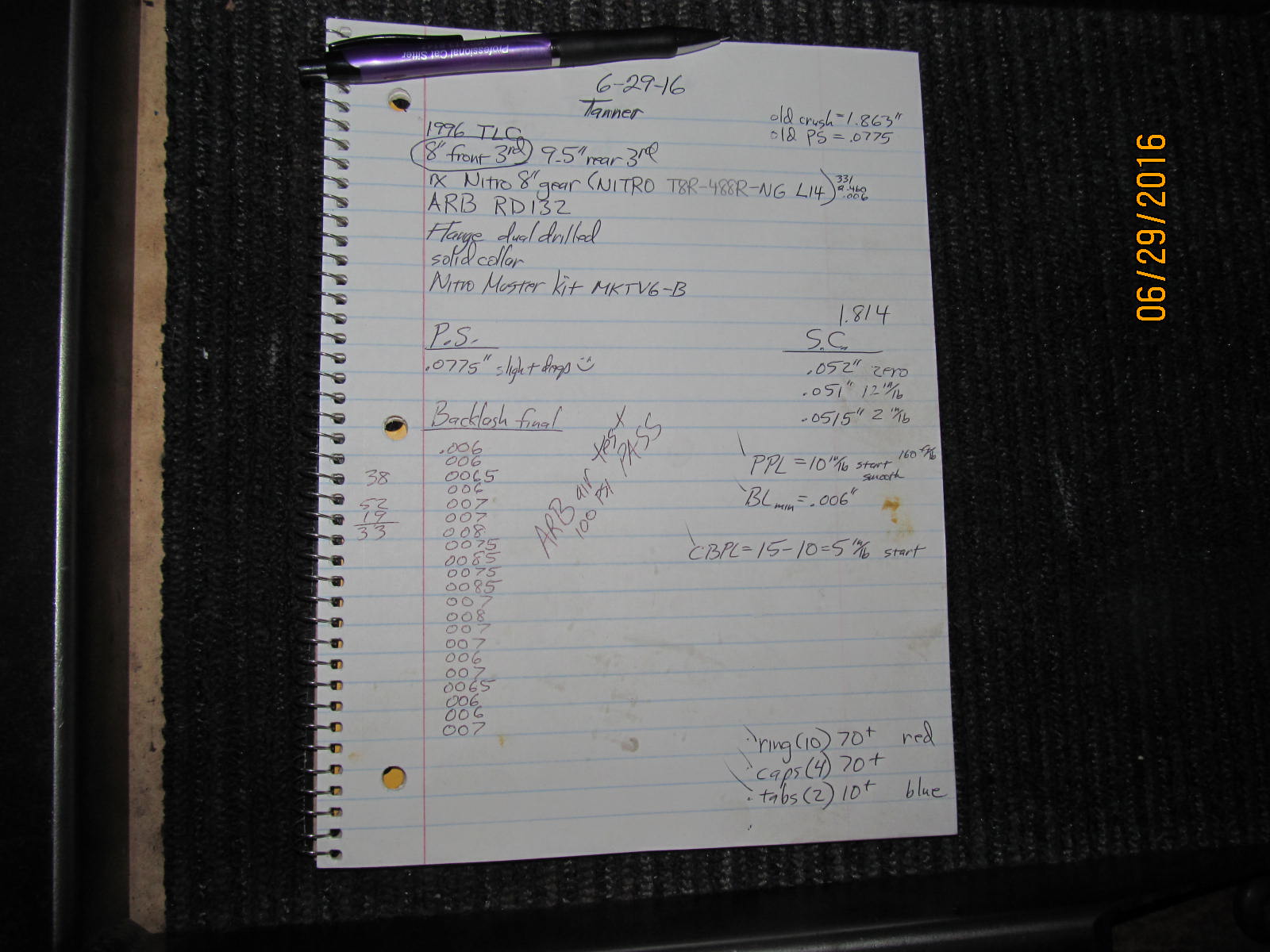

Tanner's front hi-pinion in his 1996 TLC is getting Nitro 488s, RD132, master install kit with a .....new 29

spline flange and a solid collar.

|

|

|

|

|

......................

|

|

|

|

|

Front 3rd is secured to fixture.

|

|

|

|

|

Open carrier is removed.

|

|

|

|

|

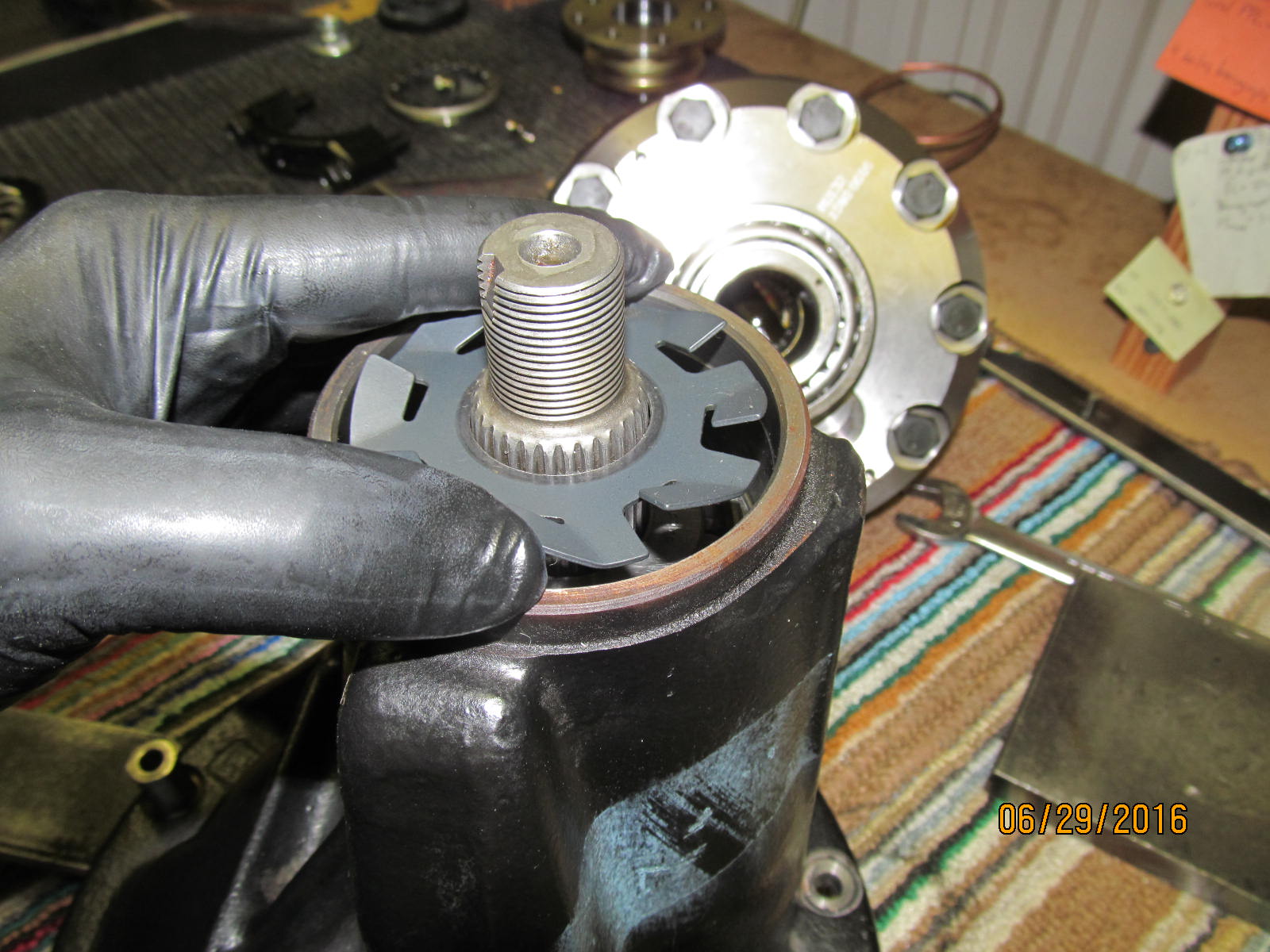

Pinion end is now dis-assembled. Taking the flange off.

|

|

|

|

|

Pressing the pinion out.

|

|

|

|

|

Seal is removed.

|

|

|

|

|

Oops...flash did not go off.

|

|

|

|

Much better...the trick is to remove the old outer pinion race without damaging or destroying the

oil retainer next to it.

|

|

|

|

|

A large washer cut in two and a plastic bottle cap work amazingly well to do just that.

|

|

|

|

|

Oil retainer undamaged.

|

|

|

|

|

New race to be inserted.

|

|

|

|

|

Tap tap and this end done.

|

|

|

|

|

Seated 100% new race.

|

|

|

|

The large inner race can be hammered in with a chisel but more "indirectly" than the way I used to do it

in the distant past. New races and direct contact with a chisel is to be avoided.

|

|

|

|

|

Big race is 100% seated.

|

|

|

|

|

Now onto the pinion itself....starter shim will be a .0775" oem shim.

|

|

|

|

|

Press on the new Koyo bearing and shim with the 12 ton HarborFreight press.

|

|

|

|

Impact down the pinion nut til some resistance is felt but not so much that the flange becomes hard to turn.

This is only for a paint test so being exact is not critical.

|

|

|

|

|

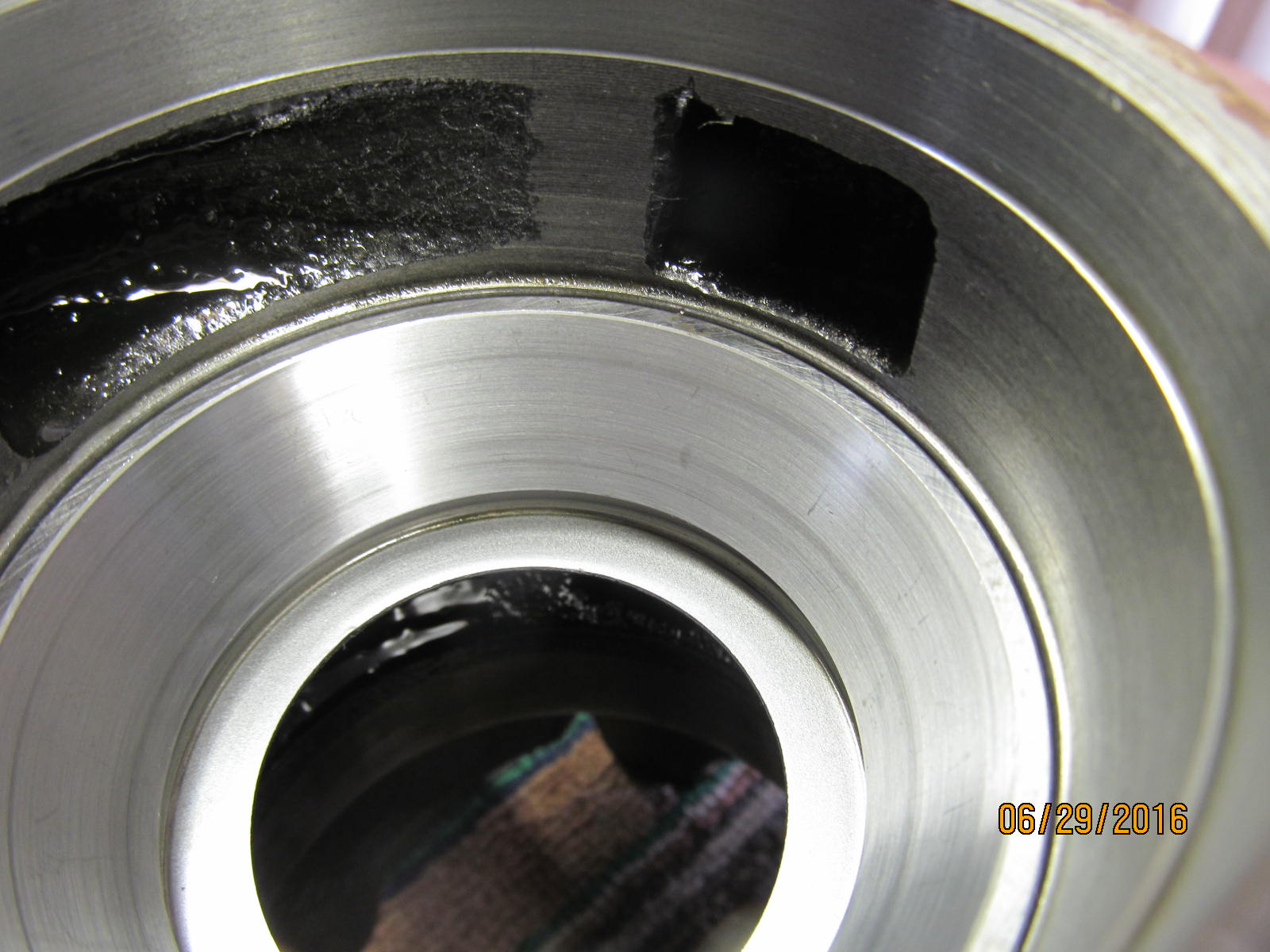

Now onto the ARB carrier end of things...surfaces are checked for burrs/high spots and all appears fine.

|

|

|

|

|

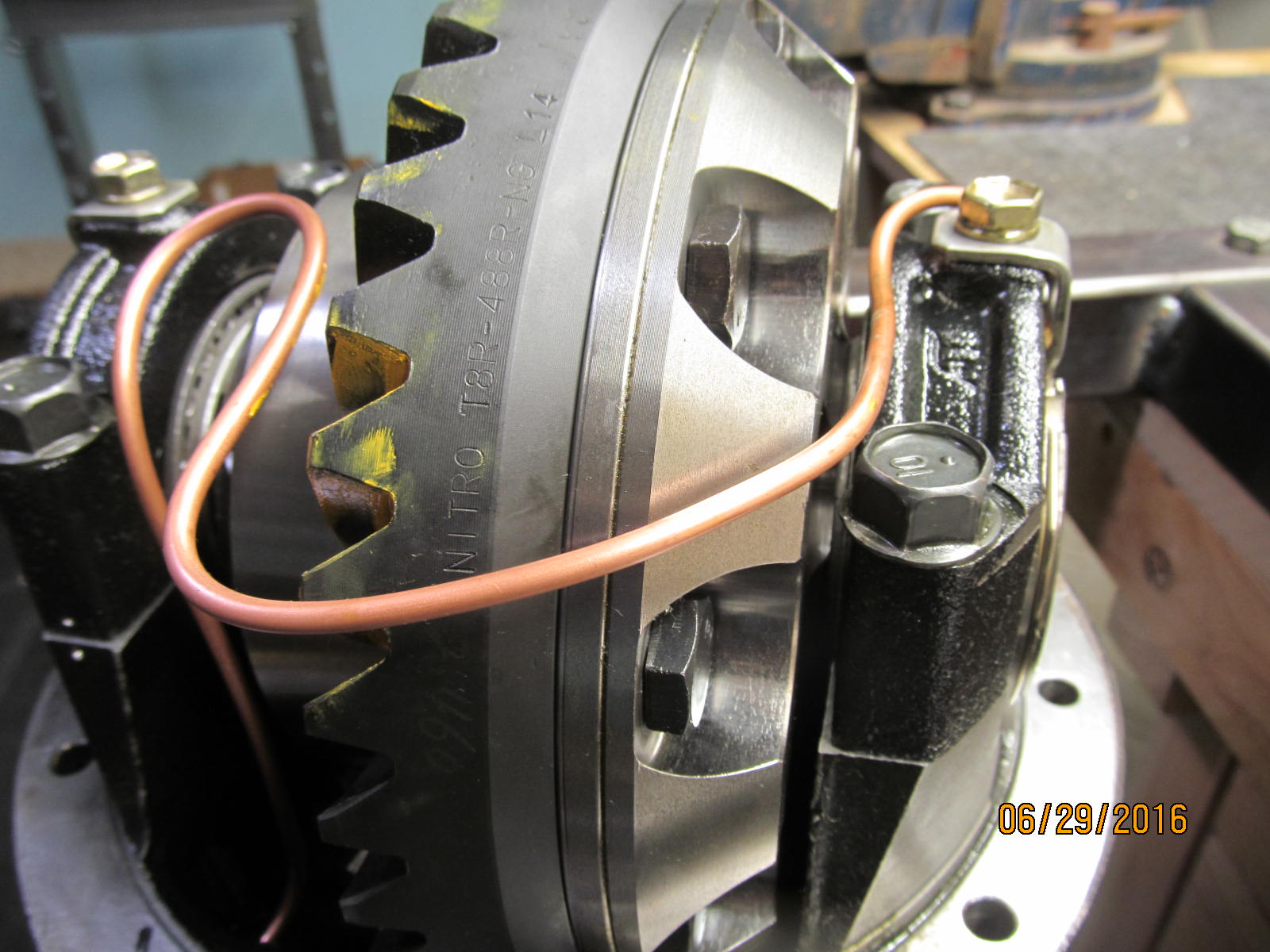

I was able to not have to use the press and tap the Nitro 488 ring down just fine here.

|

|

|

|

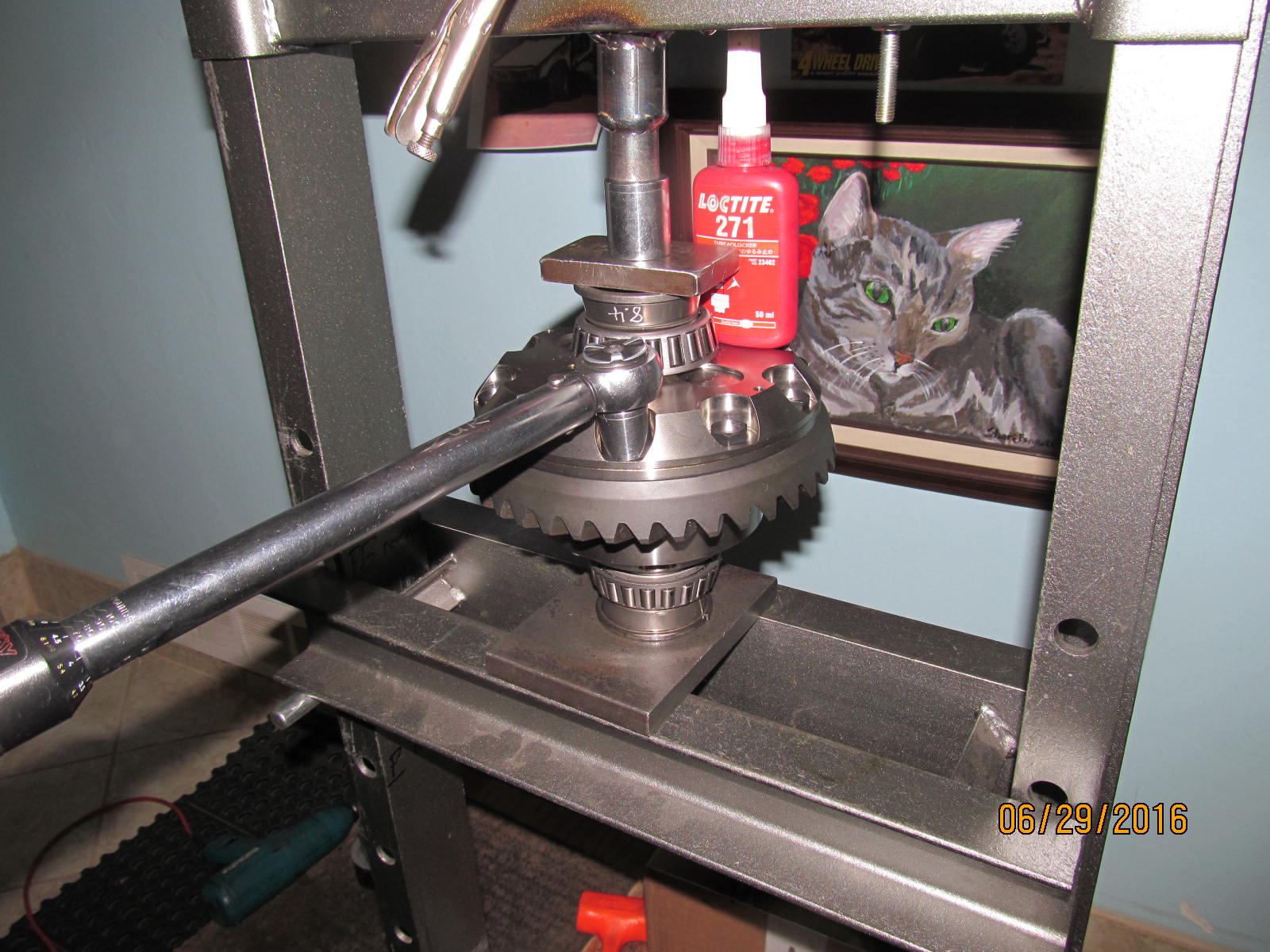

Carrier bearings were pressed on and it was very convenient to also tighten the 10 ring gear bolts

to the specified 70 ft/lb.

|

|

|

|

|

This end is done.

|

|

|

|

|

ARB is loaded in place and the wheel adjusters are carefully meshed in the threads.

|

|

|

|

|

The 2 bearing caps are snugged up and backlash is set with a small amount of actual bearing preload.

|

|

|

|

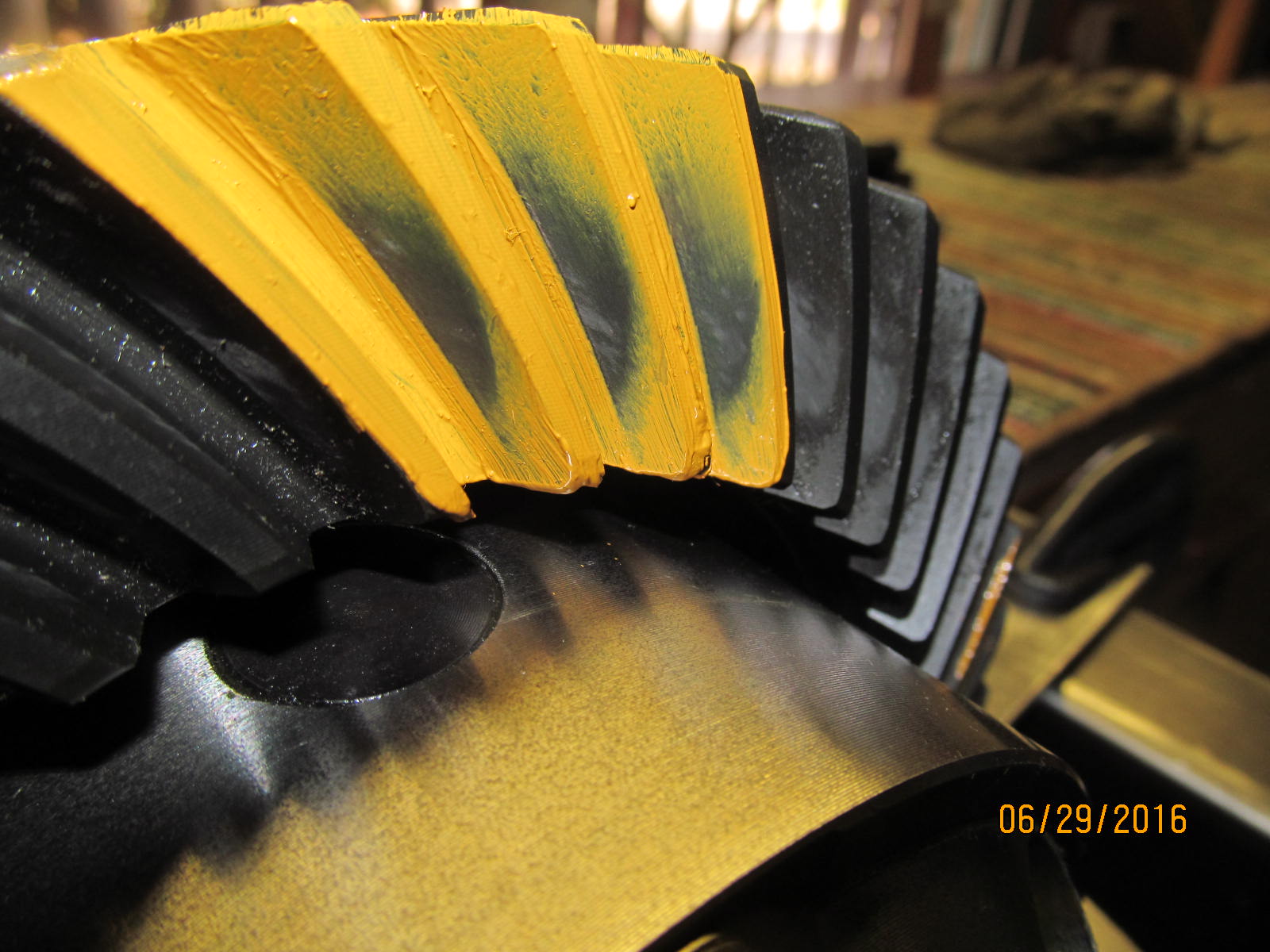

Paint test reveals that the perfect slight deep condition that I like has been achieved.

Favors the root and slight toe.

|

|

|

|

It's an added plus when the coast has the pattern favoring the toe also. The drive and coast patterns

are "synchronized" and that does not happen all the time.

|

|

|

|

|

Drive, reverse painted. Looks great.

|

|

|

|

|

Coast, reverse painted. Nice.

|

|

|

|

|

Drive....comet is in the middle.

|

|

|

|

|

.................

|

|

|

|

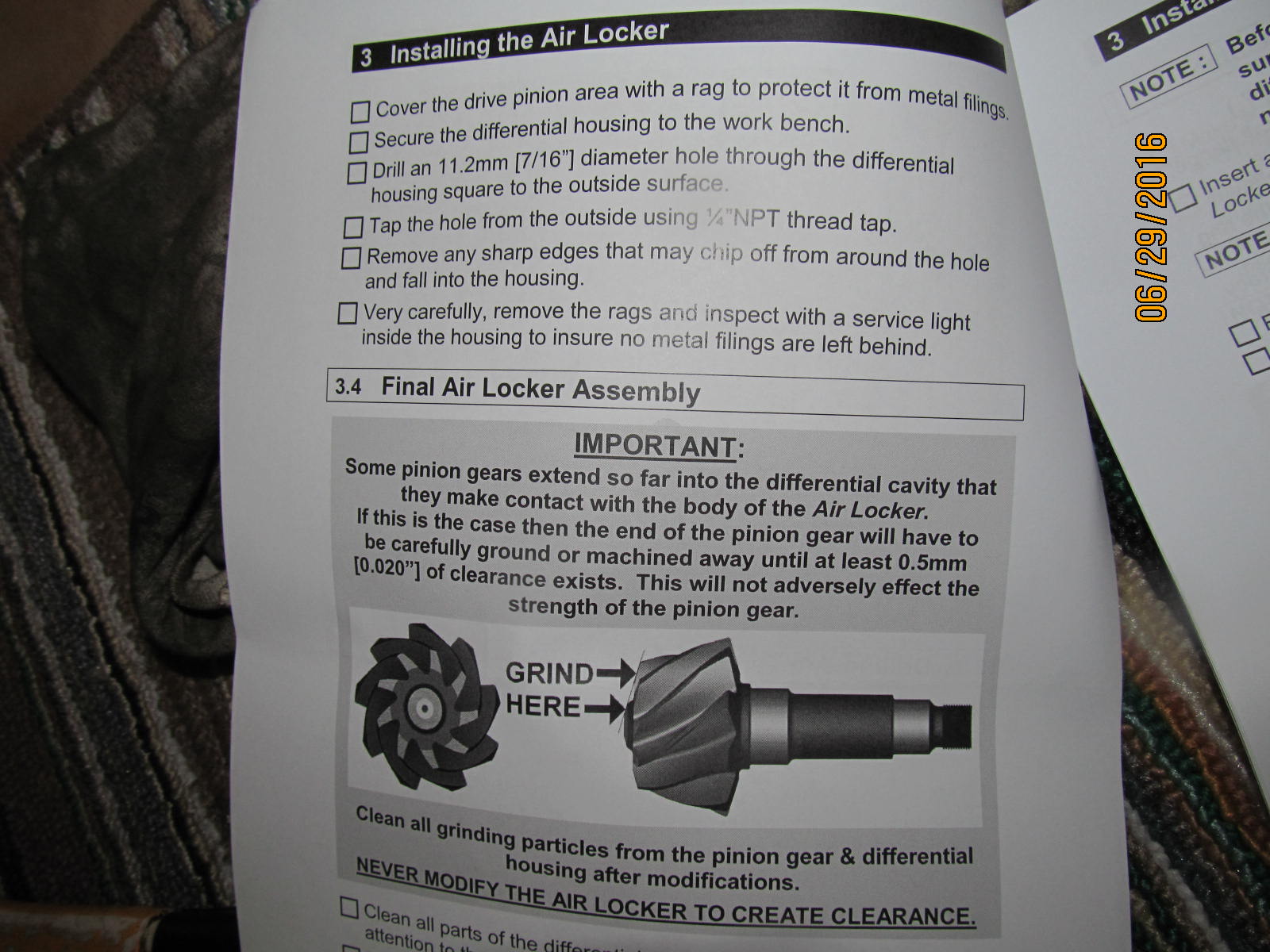

I noted the pinion was less than .020" from the ARB just before I removed it so now is a good time to

use the flapper on it.

|

|

|

|

|

A flapper wheel takes off the material with minimal heat.

|

|

|

|

|

A high speed wire wheel cleans up the burrs on the edges.

|

|

|

|

|

A snapshot of the ARB instructions on where to drill the hole.

|

|

|

|

|

The 7/16" hole I drilled ended up in nearly the same spot.

|

|

|

|

|

The solid collar can now be installed. Took only 3 times to get the shimming right.

|

|

|

|

|

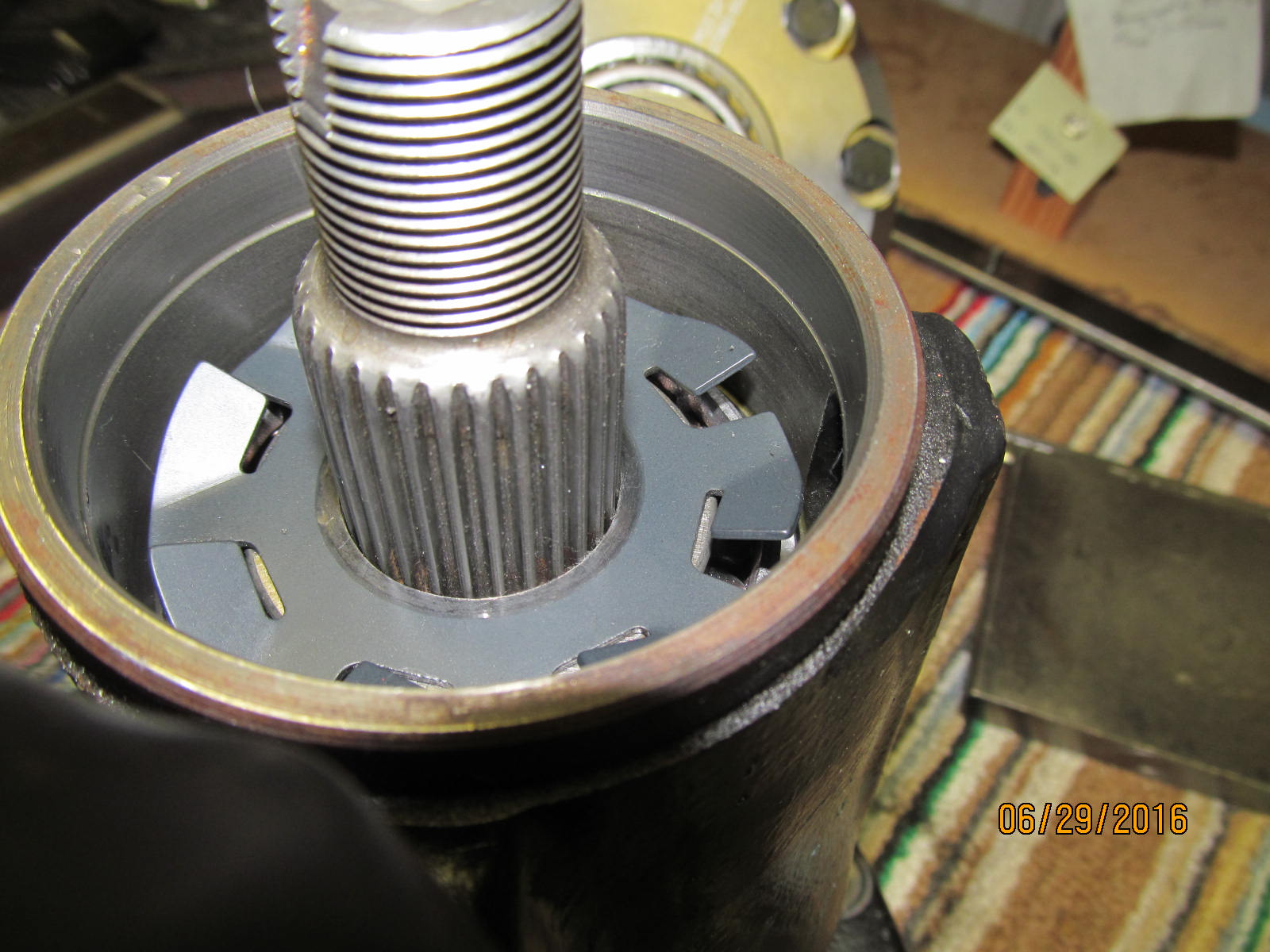

A high speed die grinder opened up the splashguard hole enough to slip over the larger 29 spline pinion shaft.

|

|

|

|

|

The die grinder operation only takes about 5 minutes or possibly less.

|

|

|

|

|

The rubberized seal is check for fit....plenty good on the tightness.

|

|

|

|

Seal is tapped in place....garter spring is verified to not have popped loose, and gear oil is applied

on all related surfaces.

|

|

|

|

|

Pinion nut is tightened until the target 10 in/lb start torque is reached.

|

|

|

|

|

DING!! and pinion end is now complete.

|

|

|

|

|

ARB case is now loaded in place...

|

|

|

|

|

The 4 bearing cap bolts are torqued to 70 ft/lb.

|

|

|

|

|

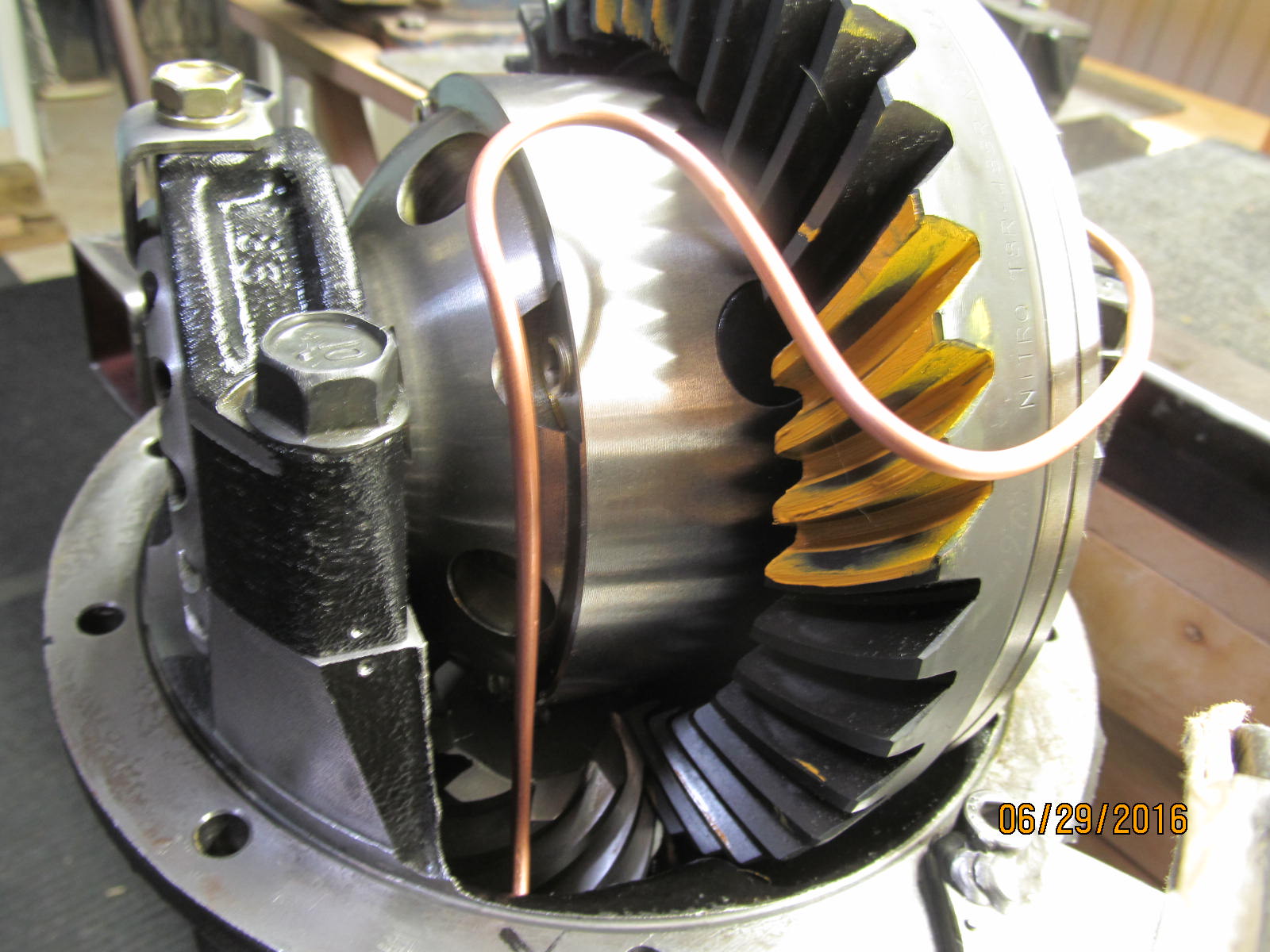

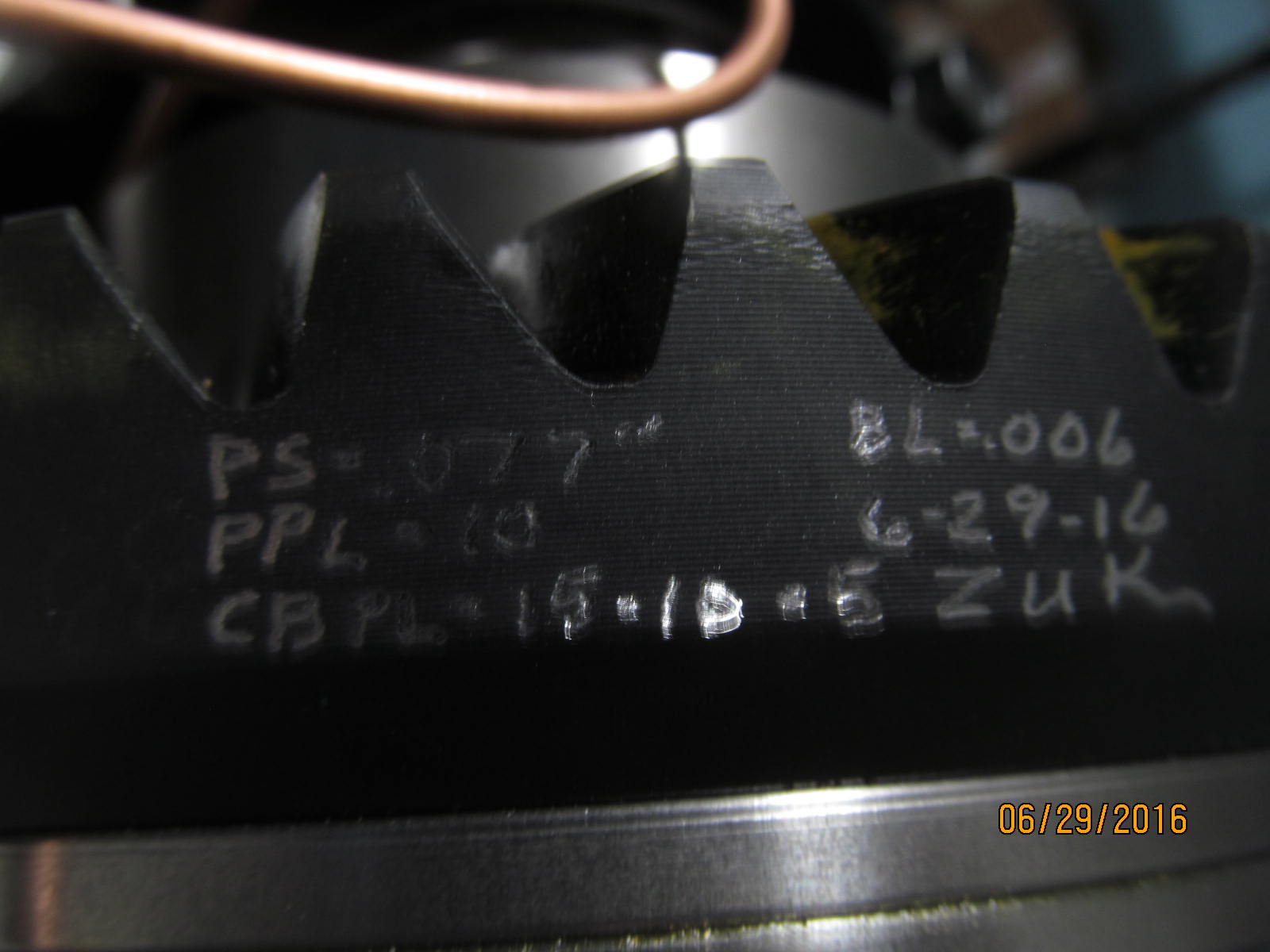

Backlash is adjusted a pattern is painted and, as seen, looks excellent.

|

|

|

|

|

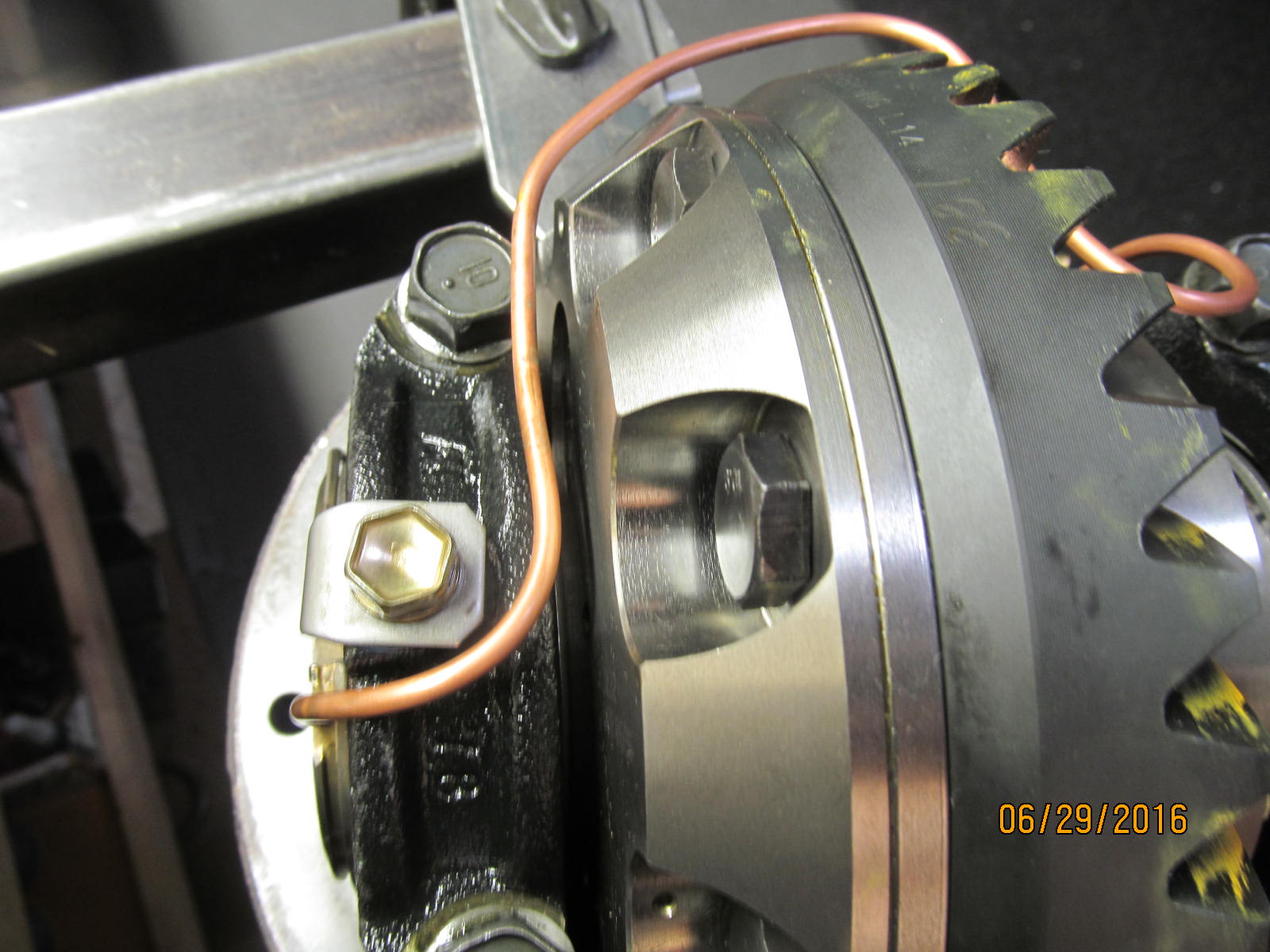

The hole is drilled and tapped...copper tube is form fitted.

|

|

|

|

|

...................

|

|

|

|

|

Excess is cut off.

|

|

|

|

|

The o-rings and seal housing assembly have just been installed. 10 ft/lb on the 12mm bolt.

|

|

|

|

|

A tiny Pepboys compressor and a 12v battery are used to run an arb test.

|

|

|

|

|

Routing is good.

|

|

|

|

|

The copper line is very soft so it can be tweaked to clear the corners to one's own preference.

|

|

|

|

|

................

|

|

|

|

|

,,,,,,,,,,,,,,,

|

|

|

|

|

Final notes.

|

|

|

|

|