|

|

|

|

|

|

Thomas from Picayune, Mississippi, has been pushing his 42" tires with 410 gears. He says it was

no fun ;) .....this is on a carbed 5 speed truck. The plan is to install high quality Precision 571 gears into

a regular "4 cyl 3rd" to get his over-all gearing back in line. |

|

Thomas couldn't find anyone local that was capable of doing a decent gear install so he found me in cyber space. New bearings and a solid collar will enhance this install. These 571 gears will last a long time inspite of 42" meats. |

|

Step one is to tear down and clean the open 3rd... |

|

Taking the old carrier bearings off is 'cake' with the right puller. I can't say enough

about this OTC-4520 puller. These pullers are on Ebay.com.

|

|

The not so glorious job of cleaning everything is done with the high speed wire wheel and lotsa starting fluid. |

|

Even the threaded ring gear holes get cleaned. The ring was briefly filed to insure a flat surface. |

|

Here, I'm using red Loctite on the clean threads and 75 ft/lbs torque. |

|

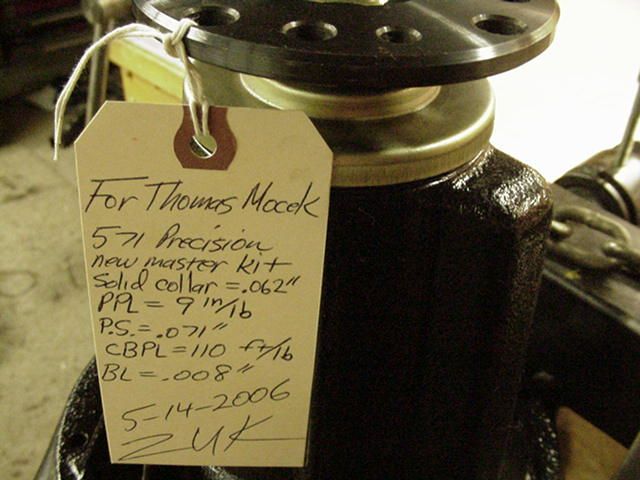

The pinion is installed first....a .093" pinion depth shim will be the first try and .066" for the solid collar shim. I had to break it down only once and change the collar shim to .062" and then the pinion pre-load was at a nice 9 in/lbs. |

|

Note to self....keep gloves in the clear while tapping the bearings down..... now I get to use the puller again :) |

|

Some shops might say this is good enough. Wash the paint off and button it up. Customer will never know the difference. That's not the way I operate. This drive side pattern is way deep. |

|

The coast confirms that... |

|

I made a big jump to 080 and still very deep. |

|

It's deep. |

|

Went down to 074 and getting close....still deep though. |

|

Coast side still agrees on being deep.... |

|

Beautiful..... |

|

Super NICE. |

|

That great pattern means nothing if the carrier bearing pre-load is set low. Sometimes, I use the torque wrench to make sure it's at least 100 ft/lbs or so. I also use the hammer to rap on the bearing caps to equalize the bearing tension. |

|

The new factory seal has a liberal coating of gear oil to prevent a dry start-up. |

|

Bullseye really is a cool bangal cat. |

|

A nice coat of black paint....a new flange....and a ZUK tag. |

|

Ready for the trip back to Mississippi. This particular box has about 4 or 5 layers of cardboard inside. No way this 3rd will break thru. |

|