|

Tim is local to me and recently took his gears out on this exact obstacle.....the fronts were in a tight bind

and even with some common sense use of the clutch, the gears went bye-bye. Tim is not running a gear eater....It's an 85 X-cab pickup

22RE 5 speed with a single 4.7 case and 36" Iroks. The 3rd was purchased about 18 months ago from a national 4x4 chain

pre-assembed and ready to go. With Tim's modest use of the clutch and his drivetrain set-up, this should have lasted much longer.

First, to do an autopsy of sorts and then install some heat treated and cryo'd 529 gears from Bobby Longfield.

|

|

|

The main damage to the ring...

|

|

|

...

|

|

|

The pinion teeth are stronger and the teeth usually stay intact.

|

|

|

This is most of the debris found in the oil.

|

|

|

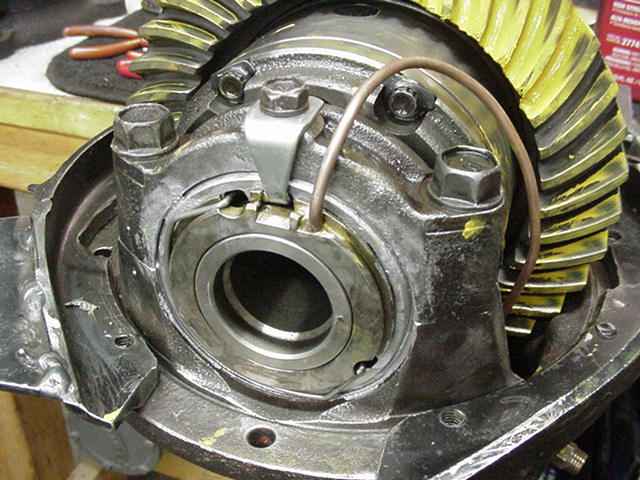

Strange that the o-ring blew out. Tim reports that the ARB worked perfectly up to the very end.

|

|

|

The special ARB adjuster wheel was tightened with the wrong tool....the chisel and hammer method is a no-no

with this adjuster. The raised ridges causes the seal housing to sit un-evenly and could cause an o-ring to

pop out.

|

|

|

Strangely enough, the commercial 3rd did not have an oil retainer...no oil slinger....and came with

just a cheap crush sleeve. This new install will have the right stuff as shown above.

|

|

|

Upon dis-assembly, I noticed that one of the adjuster wheels was not installed properly and most of the damage

was restricted to the wheel itself.

|

|

|

This is the new Bobby Long ring and pinion along with the new seal housing assembly and improved Viton o-rings.

|

|

|

The heat treatment is obvious looking at the blue discolorations.

|

|

|

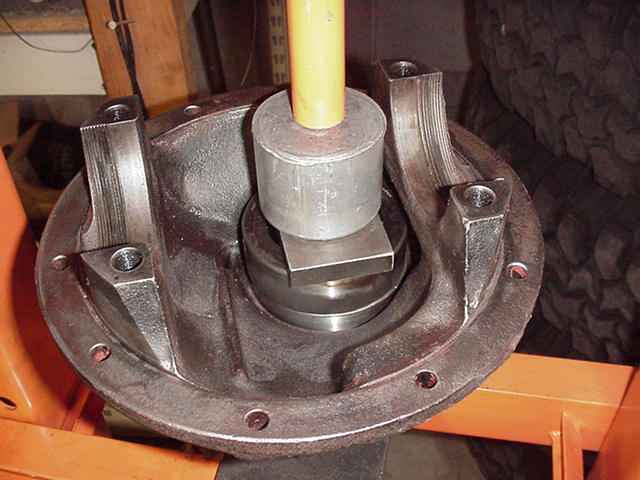

The ring is pressed on the ARB case. ARB seems to run tight tolerances and the tight fit is typical.

|

|

|

As usual, red loctite and 75 ft/lb on the 10 ring bolts.

|

|

|

Both cryo treated carrier bearings were pressed on.

|

|

|

A .079 pinion shim is pressed on with the cryo bearing.

|

|

|

The oil retainer taps into place very nicely right under the outer pinion bearing race.

|

|

|

Both pinion races are pressed in place at the same time.

|

|

|

ARB cases are just a little bigger than other cases so they are known to occasionally contact the pinion teeth.

I am being pro-active here and will use the flapper wheel to soften the edges and improve the clearance. This does

not effect strength.

|

|

|

...

|

|

|

...

|

|

|

The solid collar is left out until I get the pinion depth set correctly. The pinion nut is tightened until about 10 in/lb

of pinion drag is measured.

|

|

|

too deep.

|

|

|

heavy heel pattern...

|

|

|

Teardown and remove the bearing and lighten the shim....

|

|

|

Seems ok....but maybe I could go a little deeper now.

|

|

|

...

|

|

|

Re-shimmed to 071 and I like this much better.

|

|

|

The coast side is not as "classical". Backlash changes did not help.

|

|

|

With the correct depth, now is the time to install the solid collar and get the shim value right for it. On the 4th try,

I had a shim of .024" and 10 in/lb of pre-load.

|

|

|

Tim works on trimming the ARB copper tubing here.

|

|

|

The carrier bearing adjusters were carefully tightened to get the 150 pound pre-load.

|

|

|

Just have to ding the pinion nut and done :)

|

|