|

Tim's Front Hi-Pinion 8" Screams Just As Loud

|

|

(50 BIG pics loading)

|

|

AUGUST 19 2016

|

|

|

|

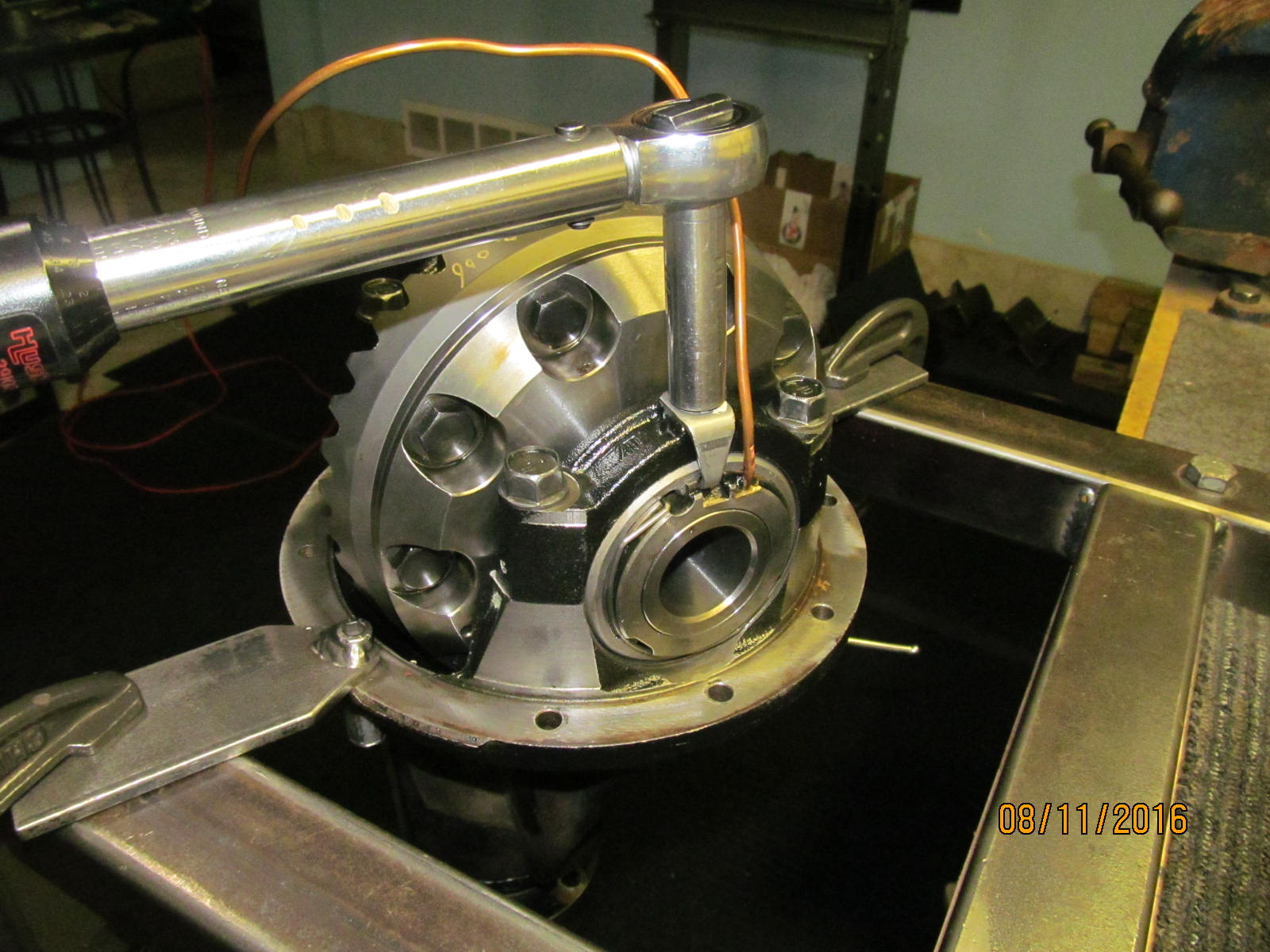

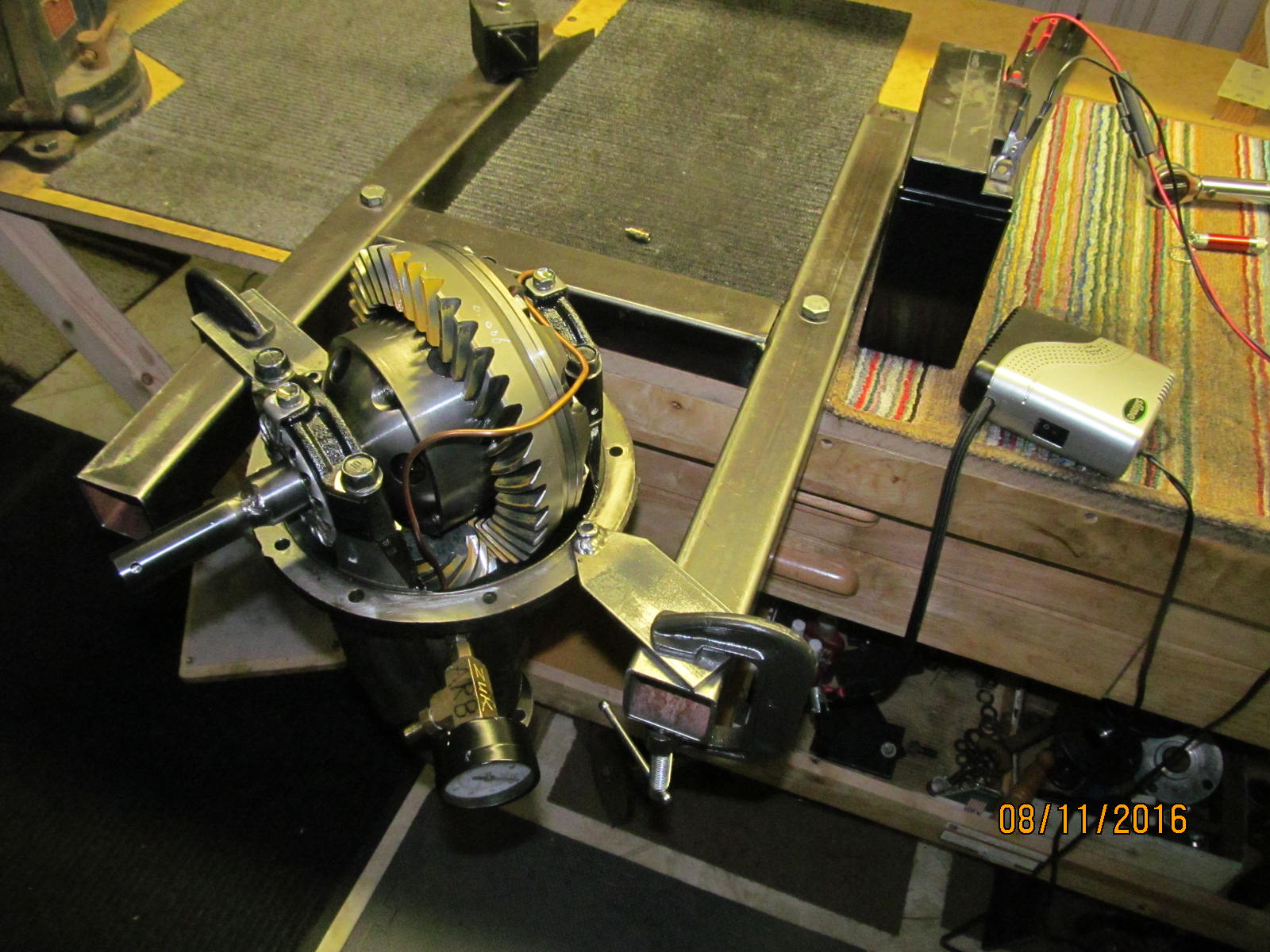

Front 3rd is mounted in the fixture.

|

|

|

|

|

Misc pieces are removed and placed off to the side.

|

|

|

|

|

Nothing too unusual with the backlash measurements or the preloads on the bearings.

|

|

|

|

|

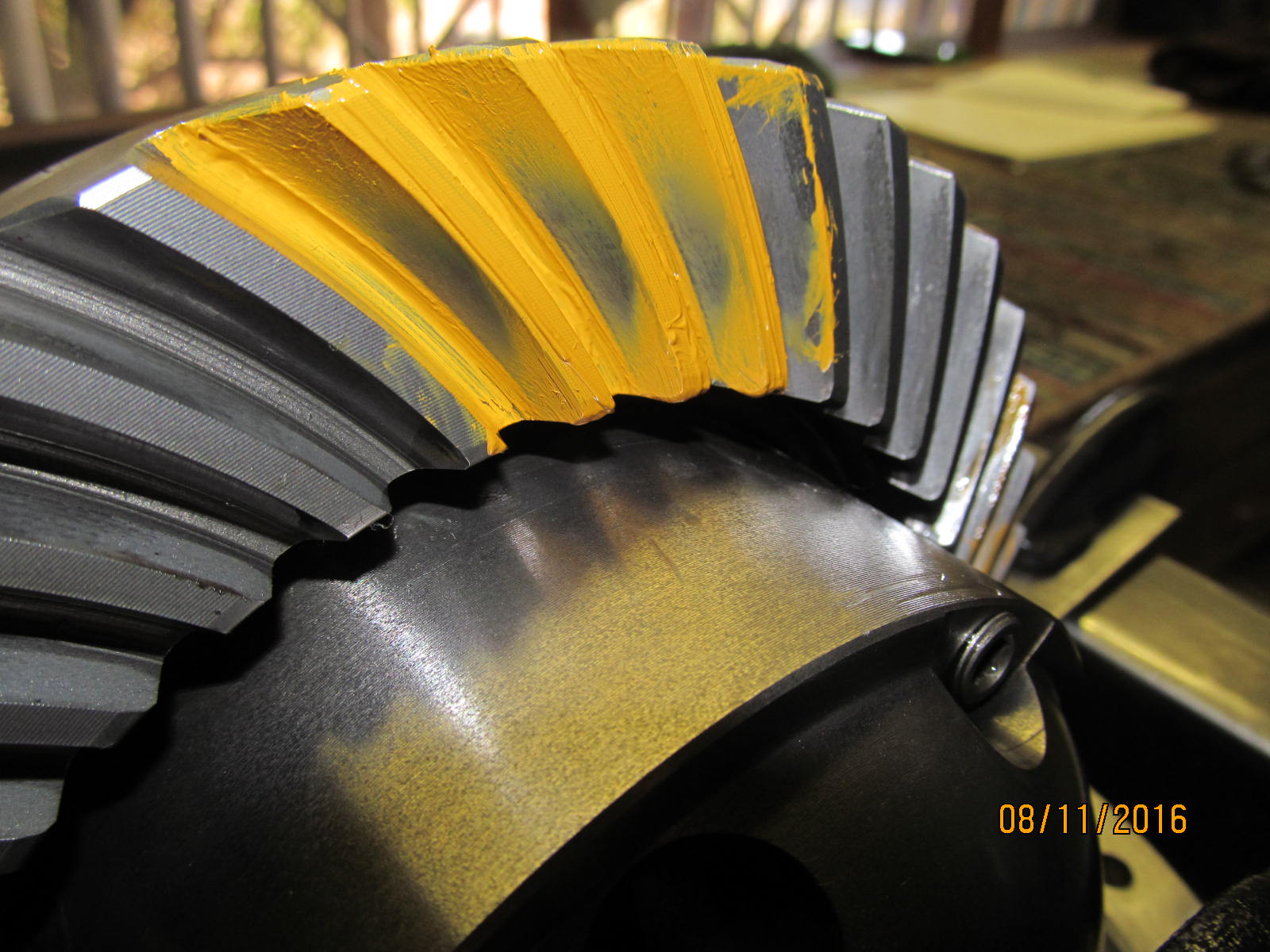

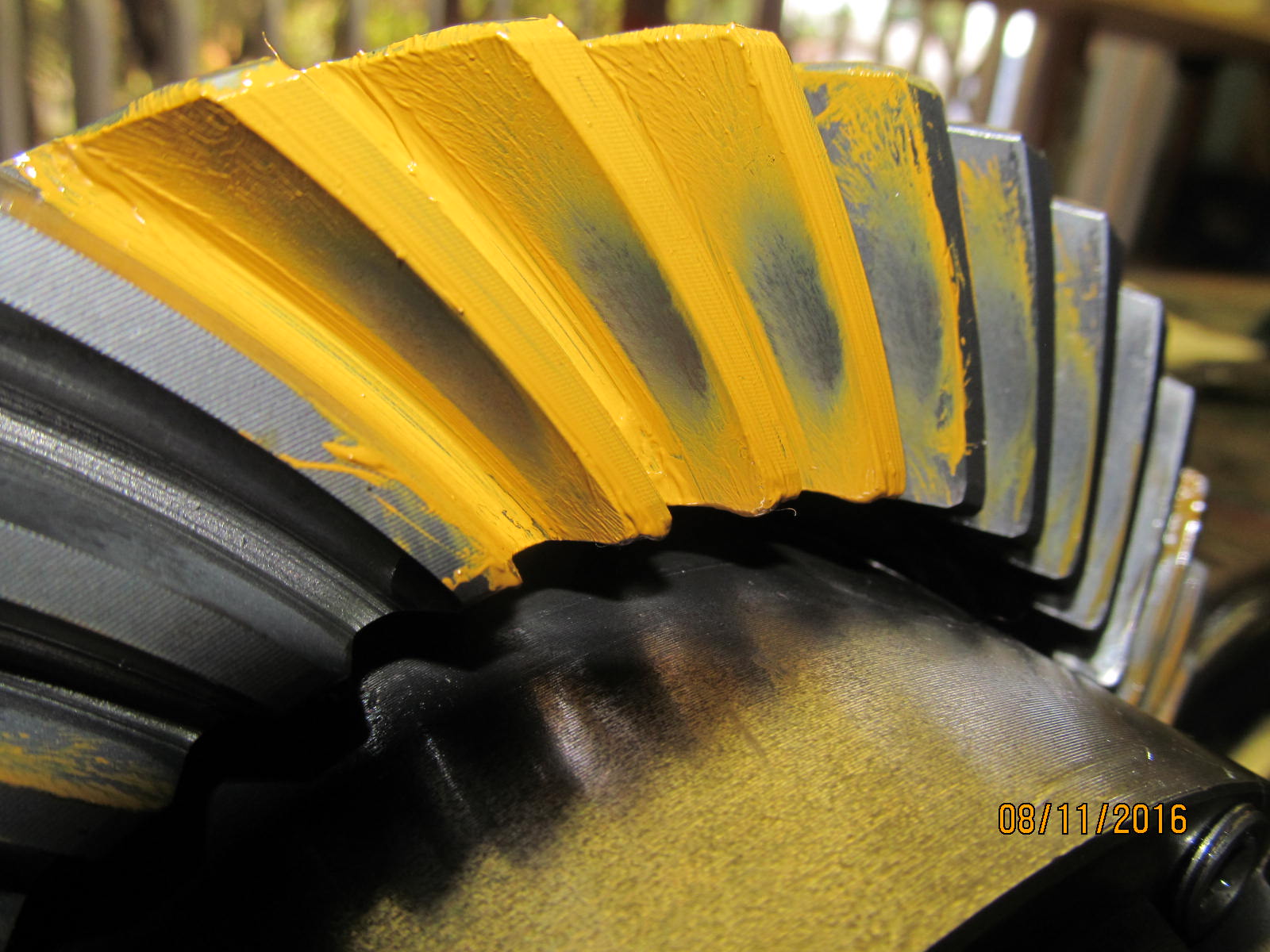

A paint of the drive side shows this diff has the same extreme shallow condition.

|

|

|

|

|

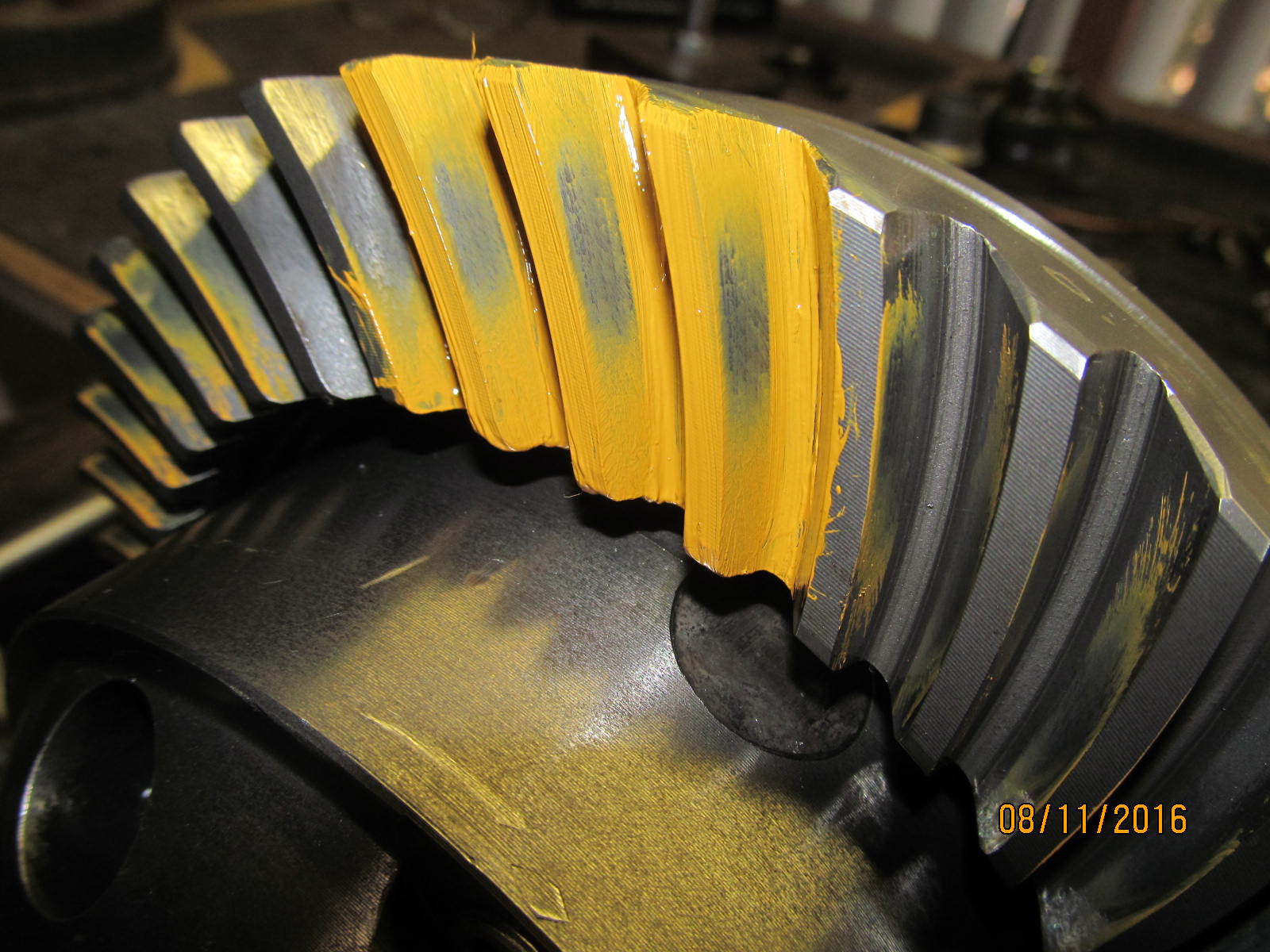

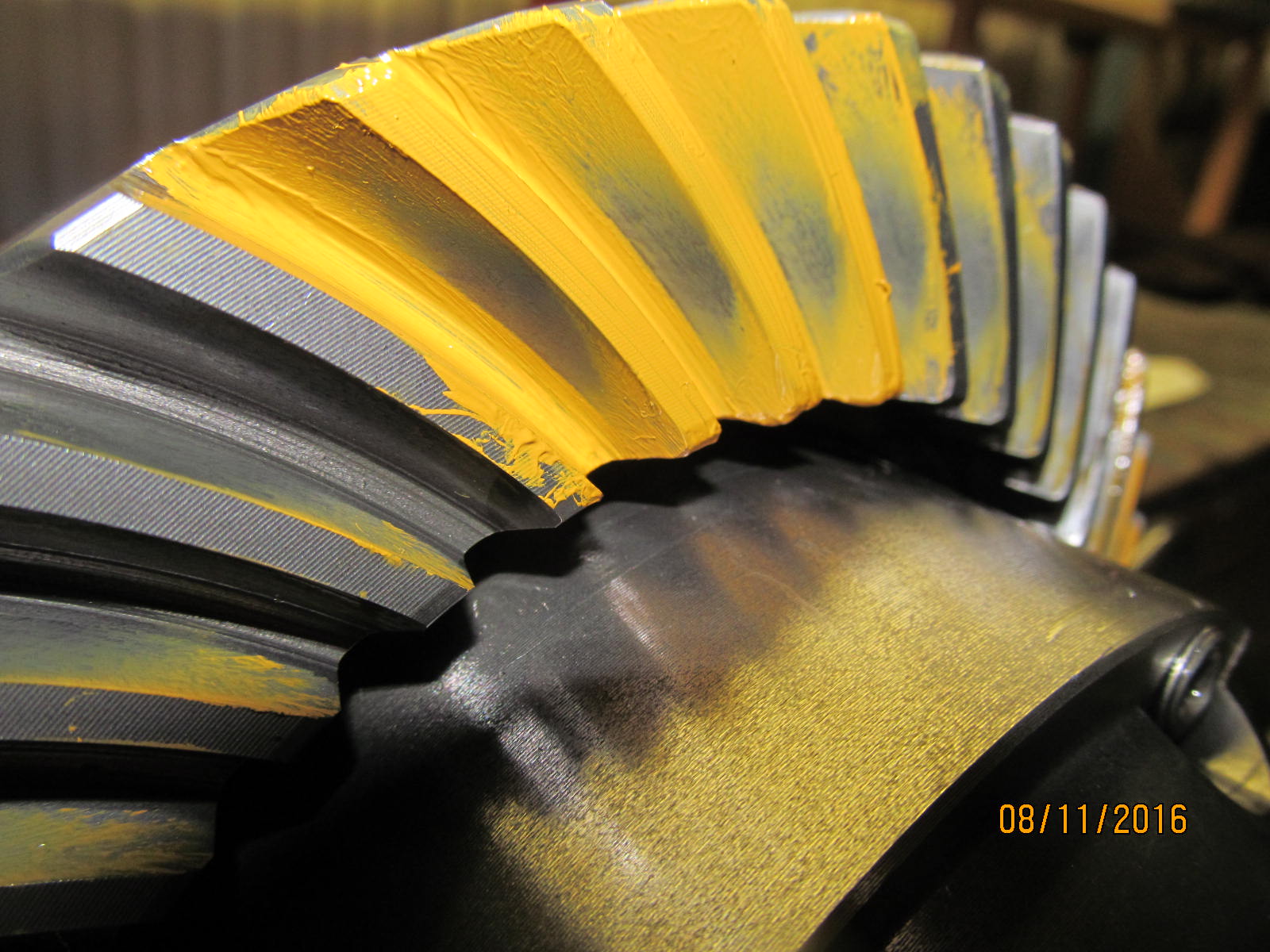

Coast just as bad.

|

|

|

|

Shown here is what a flat surface with 100 grit will do to remedy a badly schingered wheel.

A before shot is not available.

|

|

|

|

|

.........................

|

|

|

|

|

All 10 ring gear bolts were verified to be 70 ft/lb and they were.

|

|

|

|

|

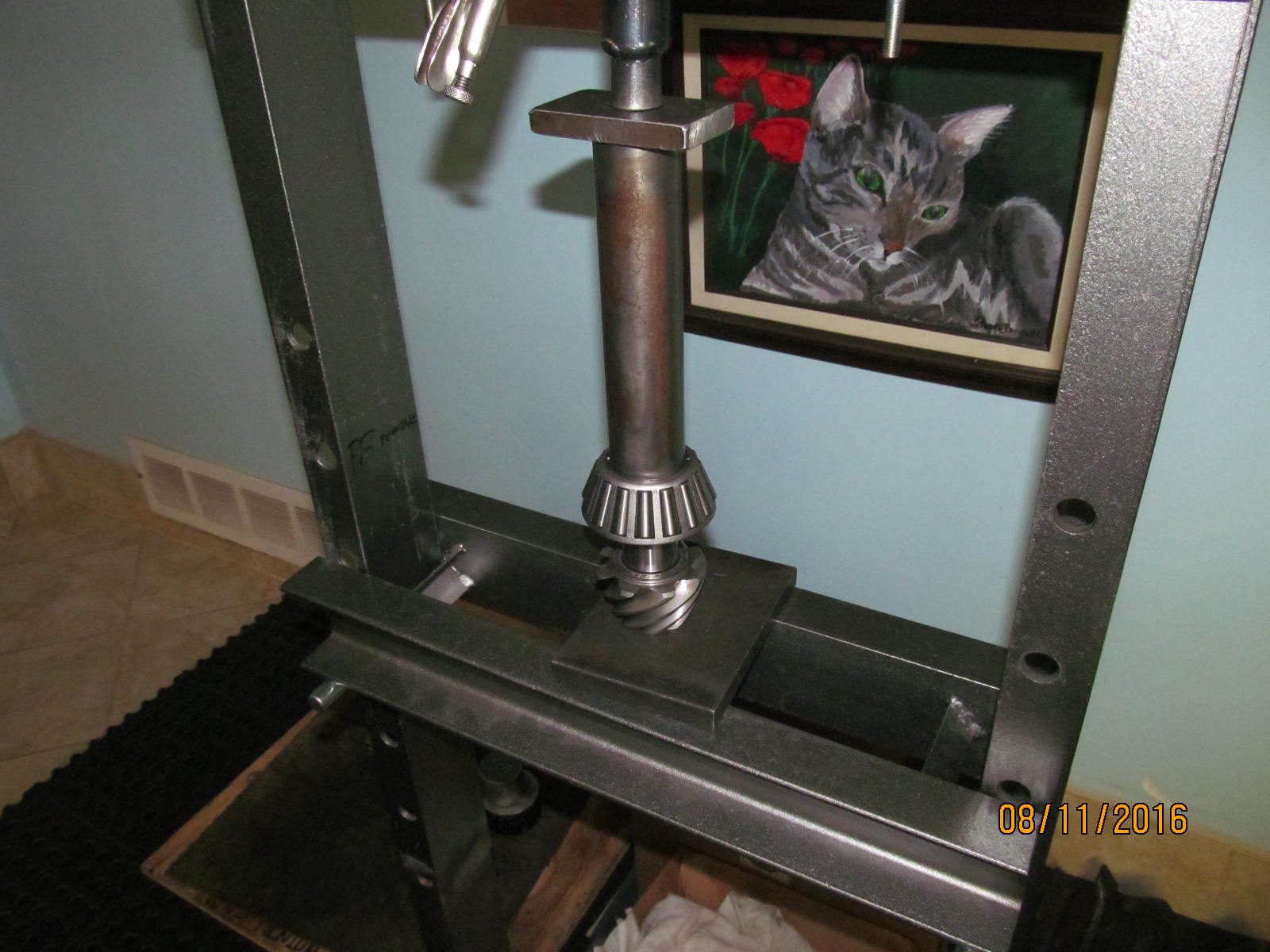

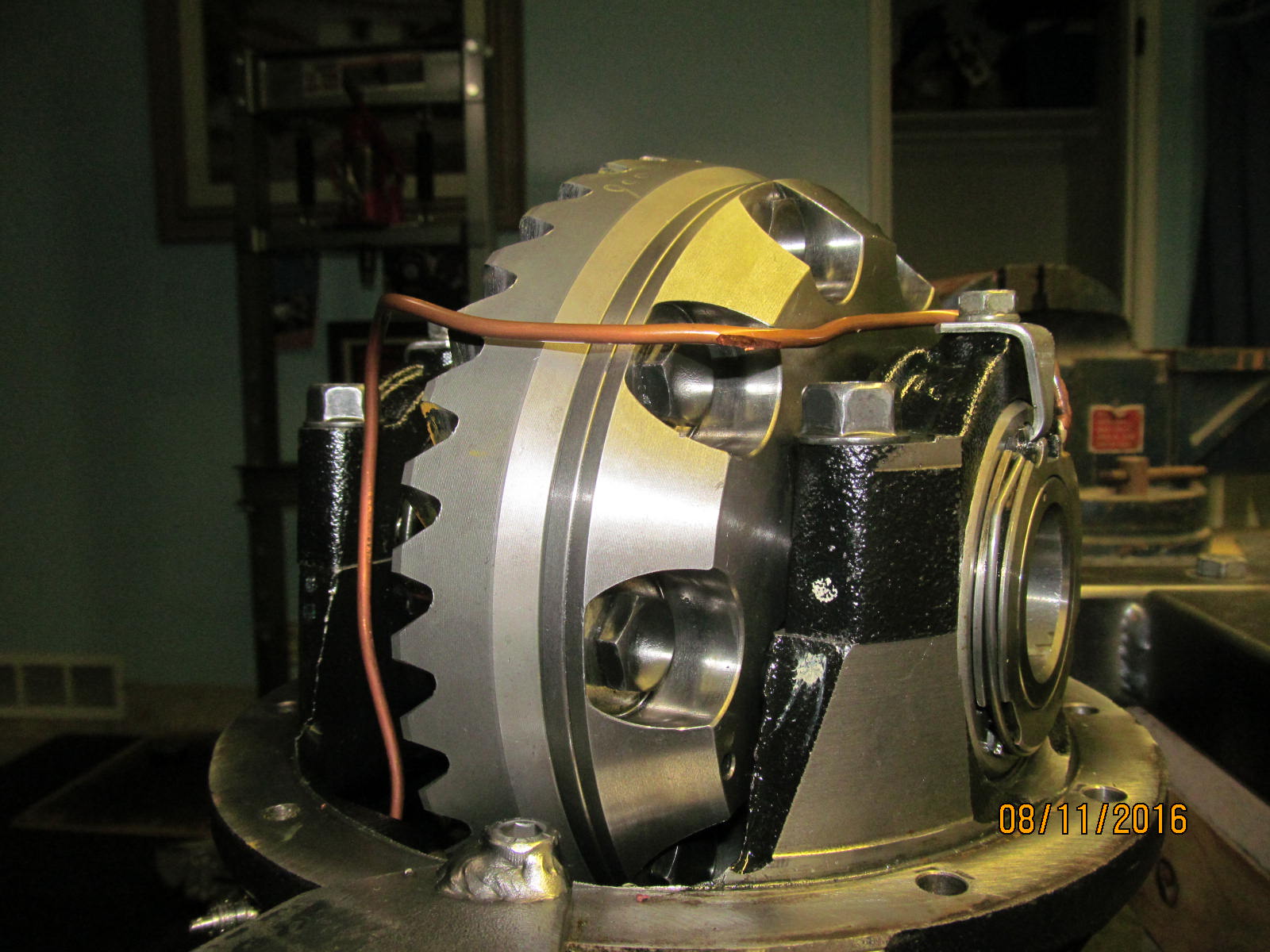

Flanged was removed and pressing out the pinion here.

|

|

|

|

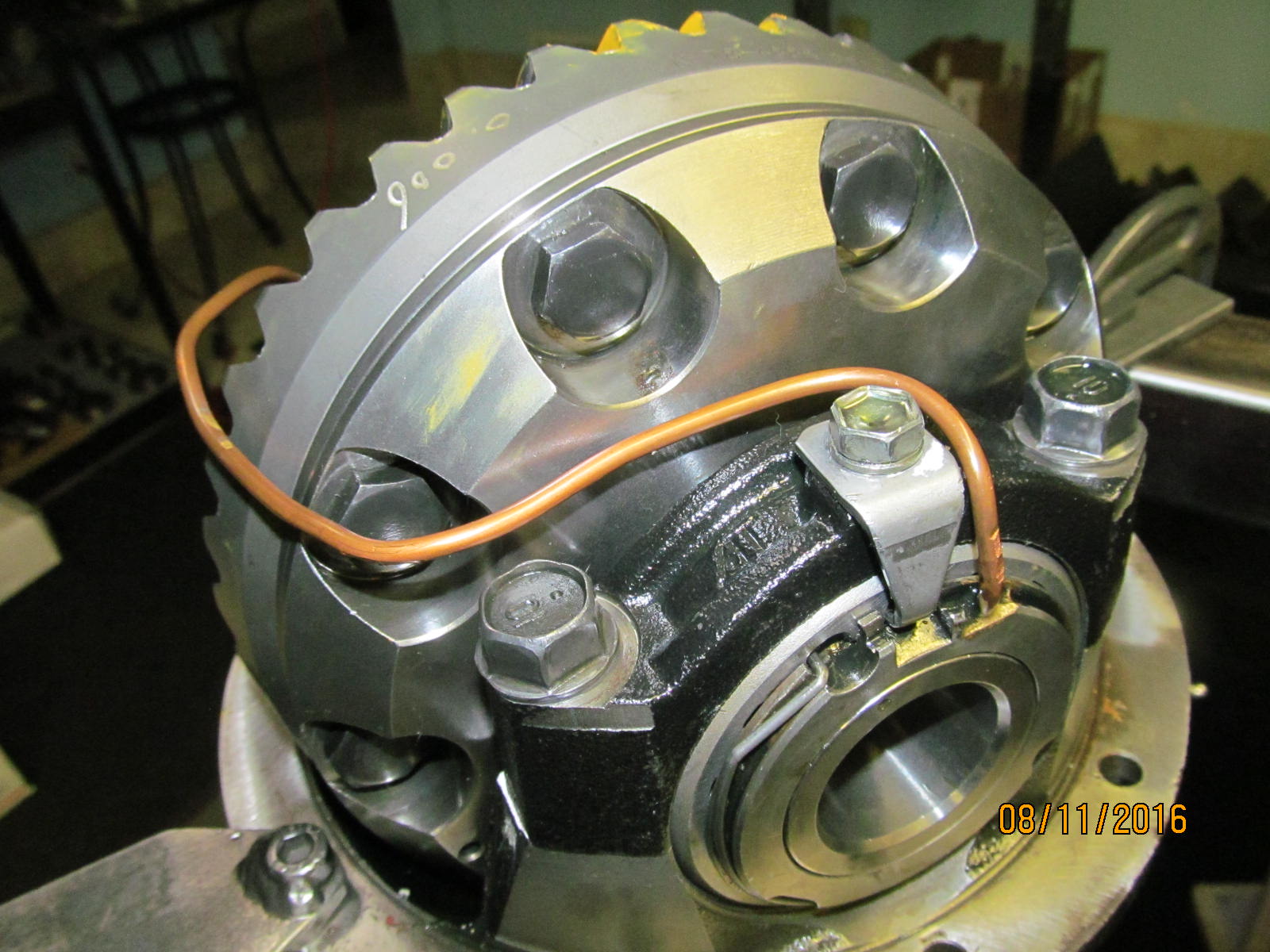

Removed the flange to discover the splash guard was in upside down. The ends of the fins must have been

smacking the rollers on the bearing with a very loud noise.

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

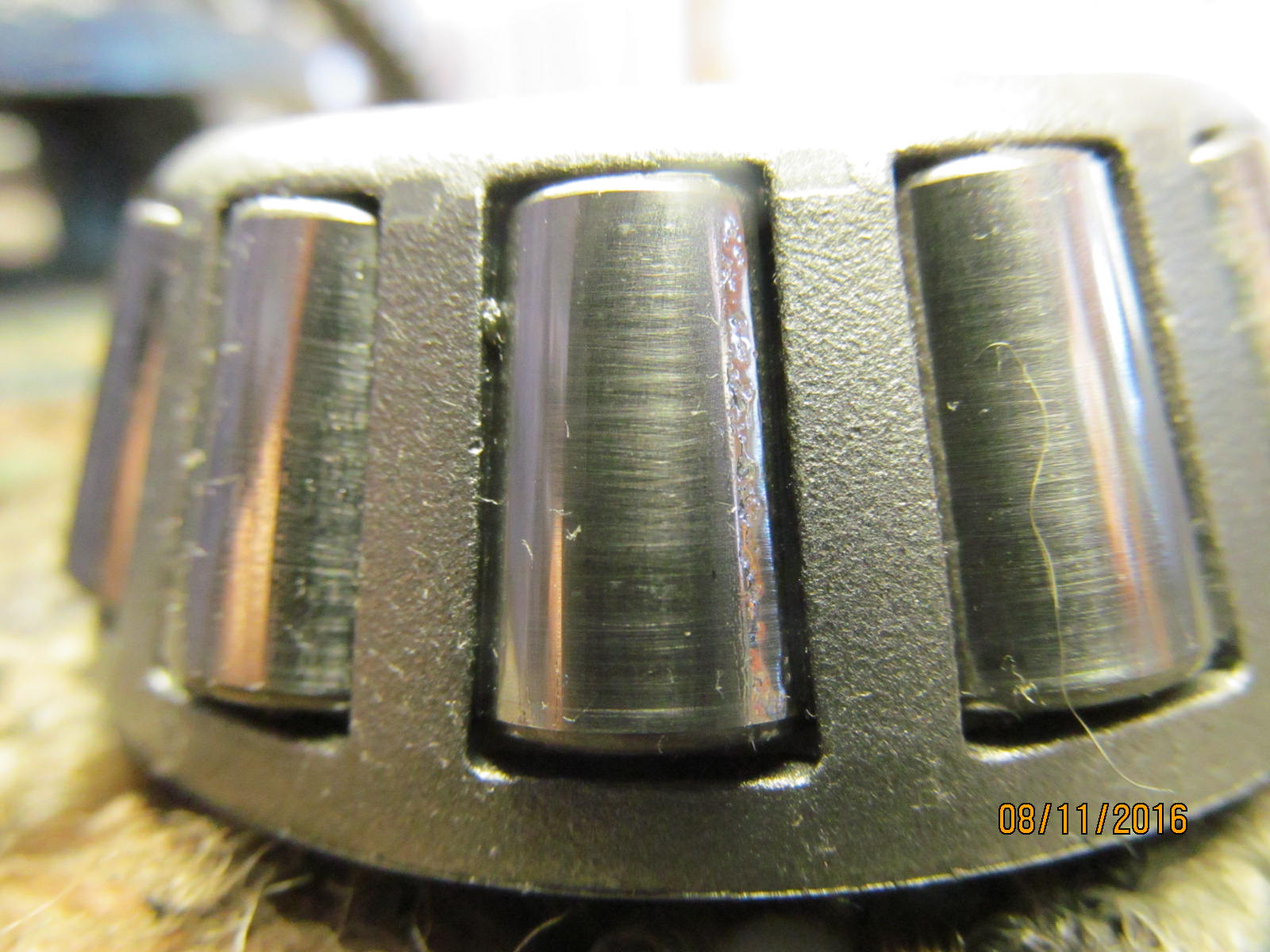

The rollers are in very good shape still. Does look like new bearings were used.

|

|

|

|

|

Tried to clean it for better presentation but that did not work out well :)

|

|

|

|

I should have used starting fluid and a clean "microfiber auto cloth" because it would show off better that these

rollers bearings are really in excellent shape.

|

|

|

|

|

The pinion races do not match that.

|

|

|

|

|

This is the large inner pinion bearing....rollers look almost new.

|

|

|

|

|

Race might have a little more wear.

|

|

|

|

|

Pressing the pinion bearing off.....

|

|

|

|

|

Where is the pinion shim?

|

|

|

|

|

Going to try a .0775" shim and see what happens.

|

|

|

|

|

Pressing the bearing on with the shim.

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

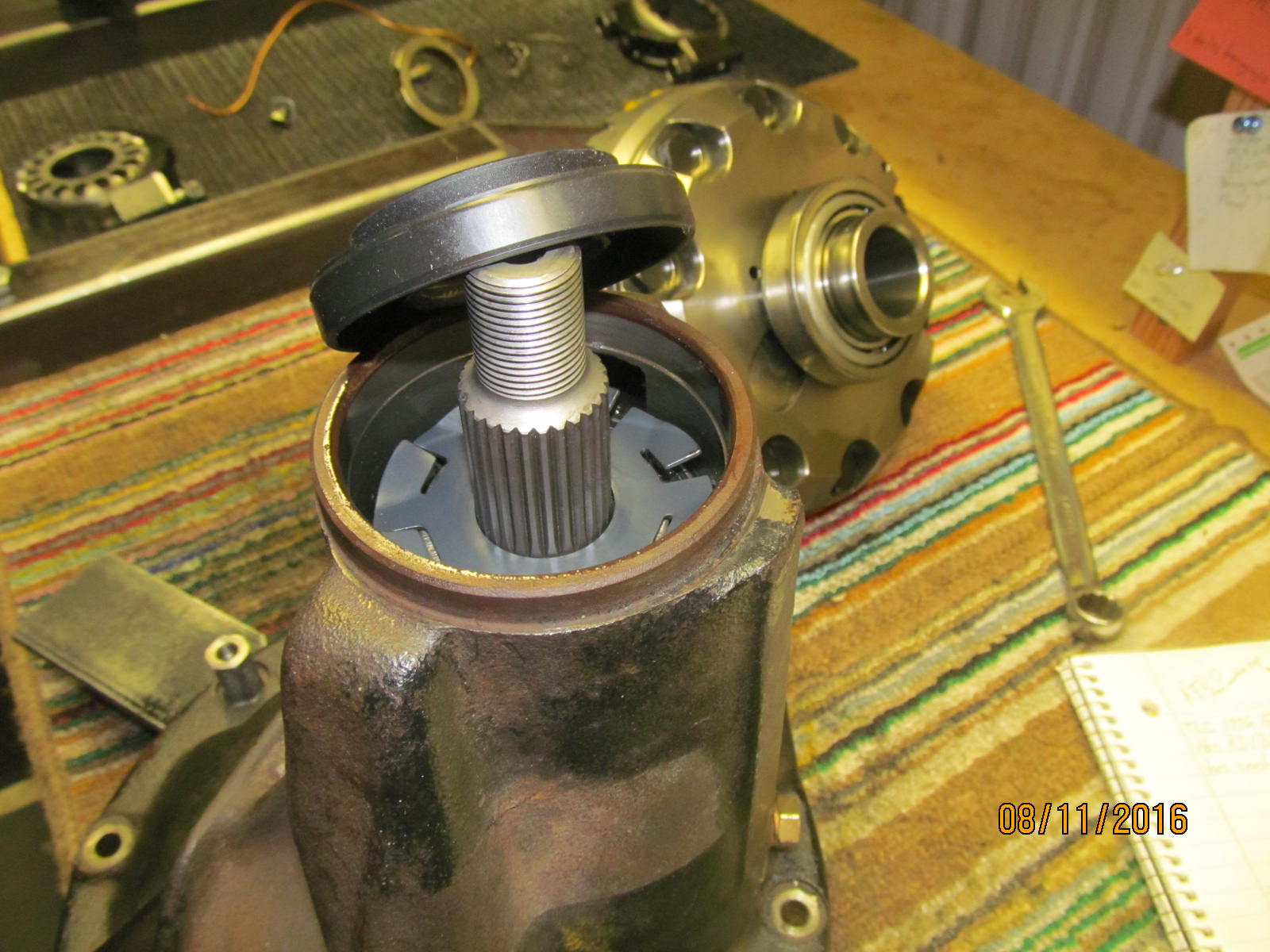

Then to mount the pinion assembly in the diff carrier.

|

|

|

|

|

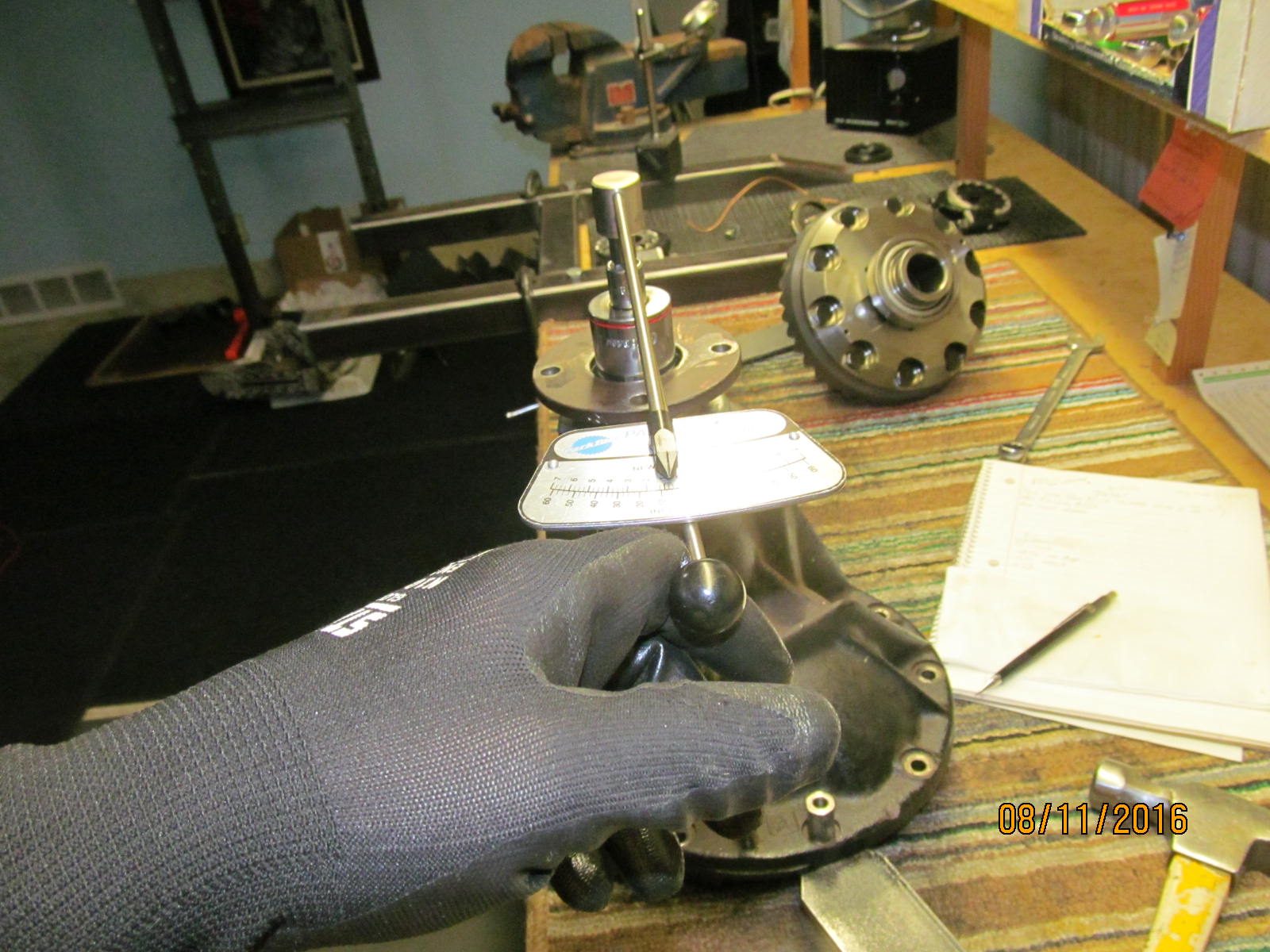

Get the backlash set to an acceptable number......

|

|

|

|

|

1st paint reveals that the pattern is too deep.

|

|

|

|

|

Coast.

|

|

|

|

|

Teardown again.

|

|

|

|

|

This time .071" will be tried.

|

|

|

|

Looks like "exact depth" and needs to be a little deeper. So I know that .0775 is too deep and 071 is exact

so if I go 073 then we will be "slight deep" and good to go.

|

|

|

|

|

Coast.

|

|

|

|

The original crush sleeve can be re-used because it was never crushed properly in the first place.

Assembly can happen now without a final paint check. The splash guard is installed right side up this time.

A new seal is used.

|

|

|

|

|

Pinion flange is installed.

|

|

|

|

|

Crush sleeve had to be crushed another 1/8 turn before 4 in/lb of PPL was observed.

|

|

|

|

|

A mild 4 in/lb of preload was measured.

|

|

|

|

|

DING and this will never loosen up on its own.

|

|

|

|

|

The 4 bearing cap bolts are torqued to 70 ft/lb.

|

|

|

|

|

Backlash is recorded on every other tooth....over 20 measurements. I noted the minimum BL to be .006".

|

|

|

|

|

This is the preferred condition....slight deep.

|

|

|

|

|

Coast

|

|

|

|

|

Total preload is measured at 13 in/lb.

|

|

|

|

|

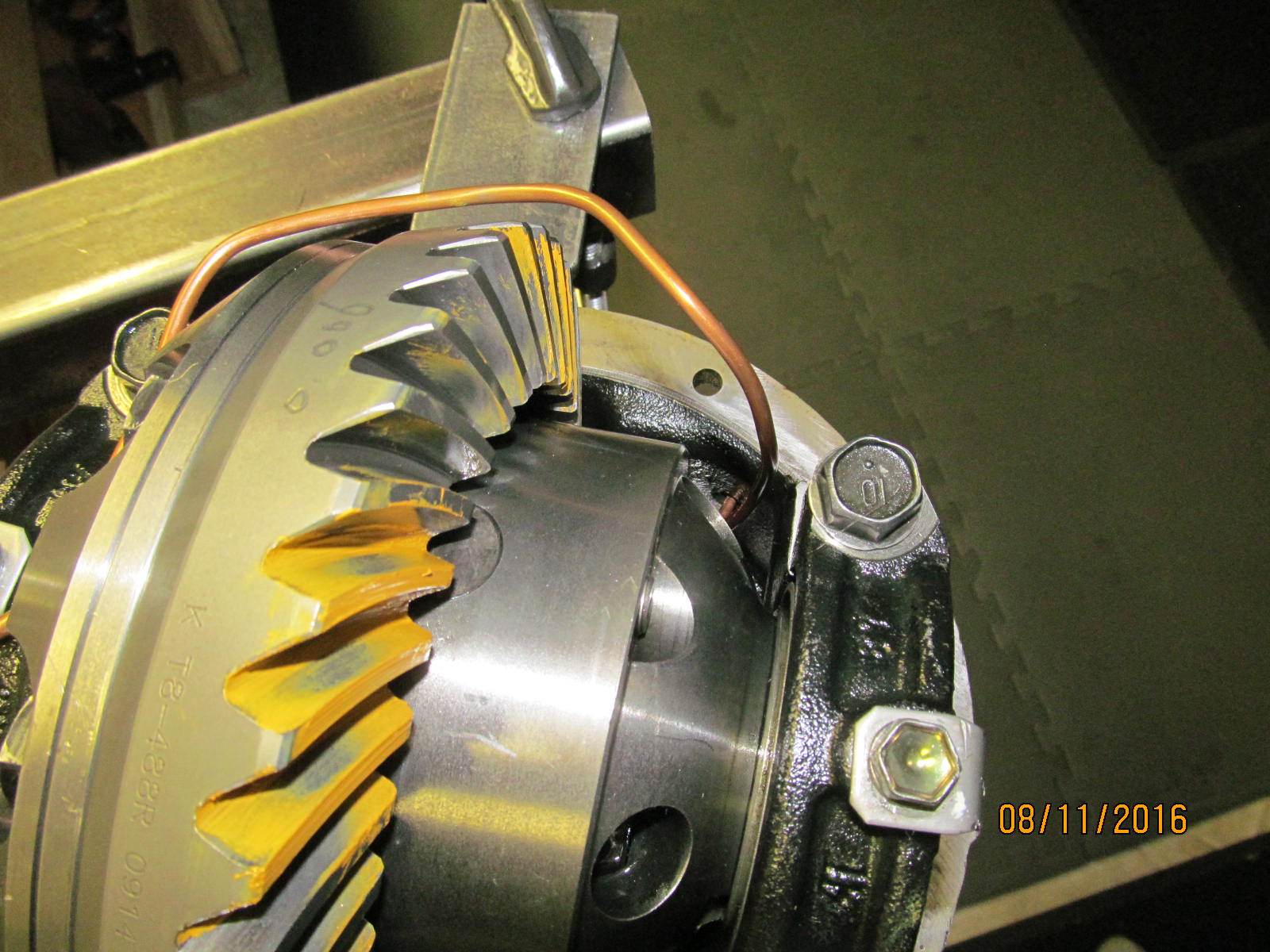

ARB seal housing assembly is installed and the 2 tabs are now torqued to 10+ ft/lb.

|

|

|

|

|

ARB is checked for leaks and none found.

|

|

|

|

|

Routing is confirmed.

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

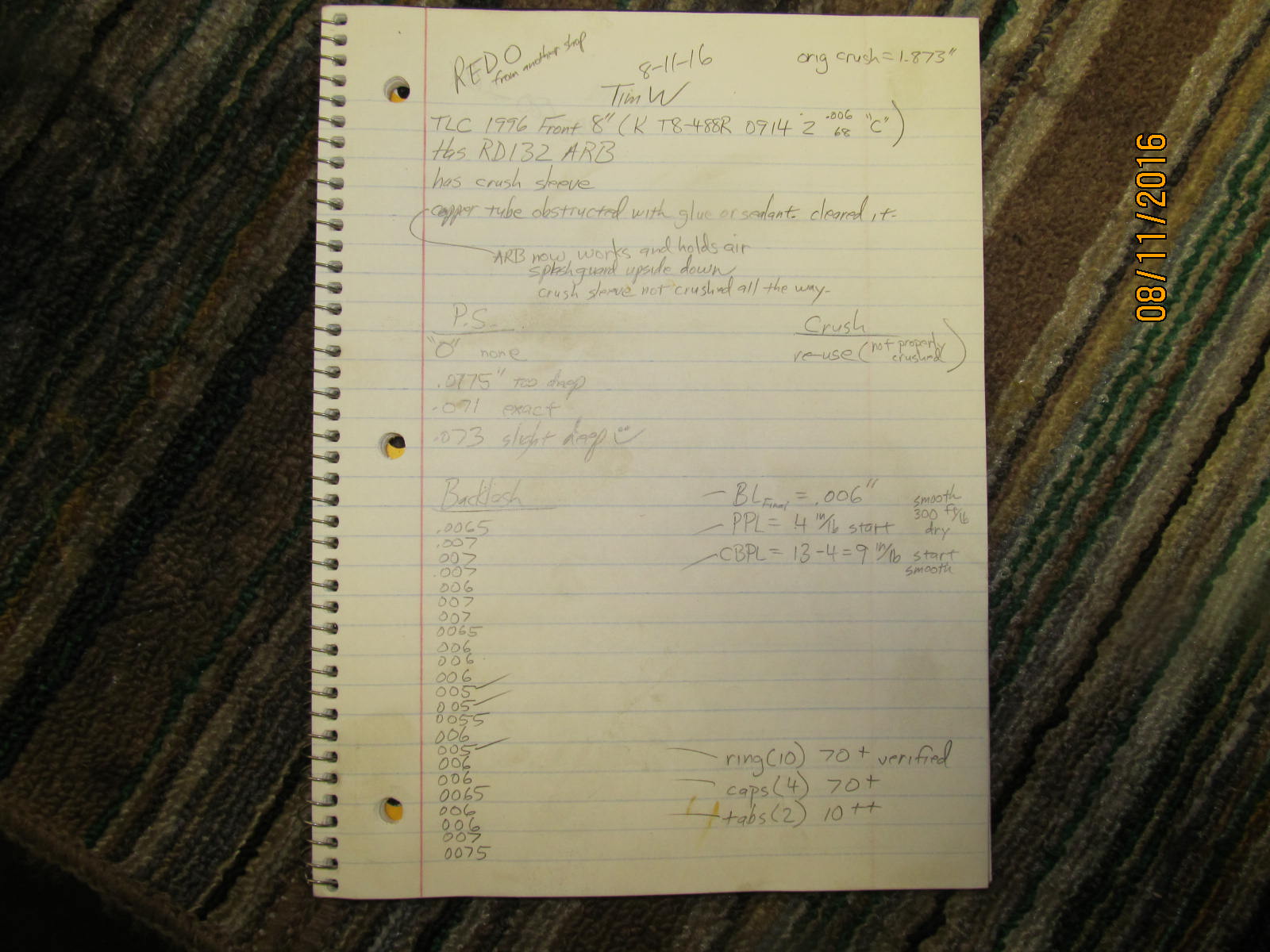

Notes are noted.

|

|

|

|

The original double box did very well and is still re-usable. The lip of the diff did ding the bottom and

leave a touch of oil there but no issues with that.

|

|

|

|

|

Taking extra precautions to cushion the entire diff on the bottom.

|

|

|

|

|

This is good.

|

|

|

|

|

Ready for Fedex now.

|

|

|

|

|