|

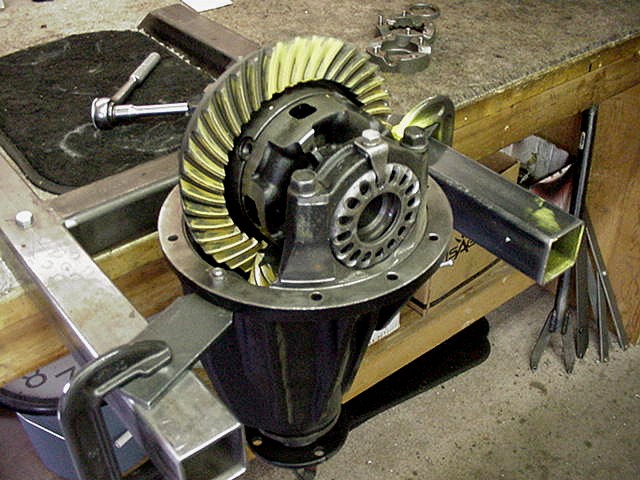

The 8" V6 3rds are commonly found in 1988~1995 3.0 V6 trucks and Runners. Also found in 86 and 87 turbo trucks. And even some of the

post 1995.5 Runners have them also. Installing a Lockrite in them is actually easy.

|

|

|

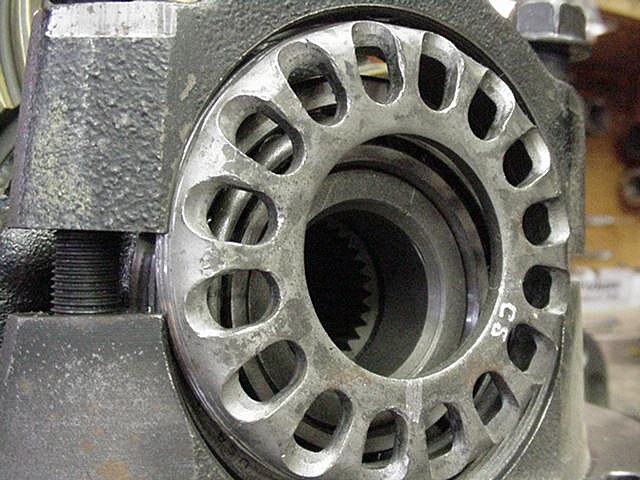

The most important step is to mark both adjusters BEFORE dis-assembly.

|

|

|

I engraved a little CS (CaseSide) on the wheel to make sure it goes back on the right side. Loosen

the adjuster wheel and then remove the bearing caps. It's probably a good idea to mark the bearing cap also.

|

|

|

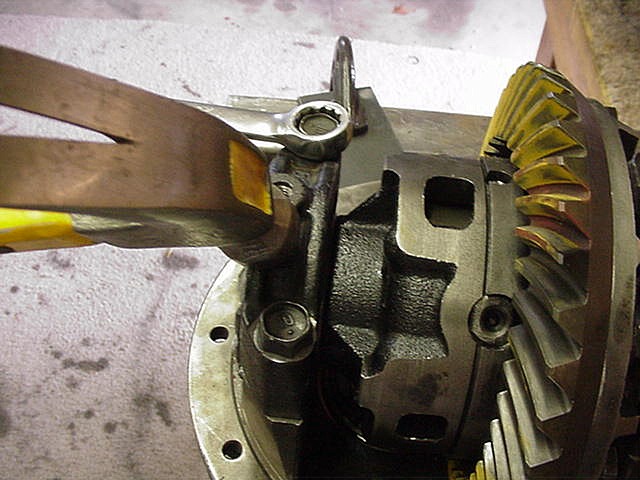

Now the case comes out of the carrier and remove the 8 bolts with your favorite electric impact wrench.

|

|

|

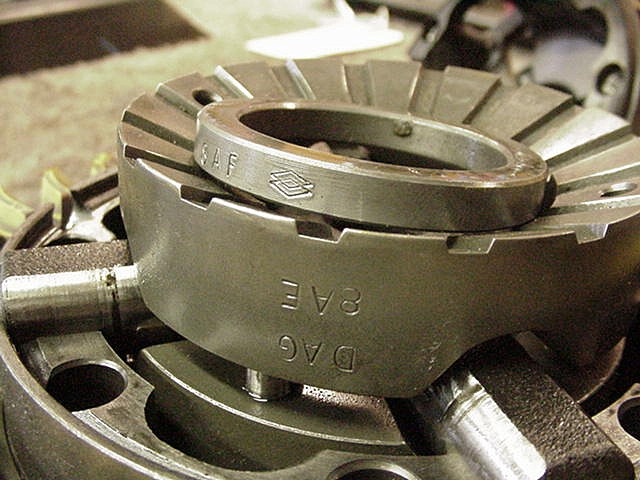

There is no need to remove the ring gear because the case splits open like this.

|

|

|

Remove the cross with the spiders on it and load one of the Lockrite couplers and a spacer washer. Also load

2 pins and the springs in it.

|

|

|

Remove the 4 spiders and place the cross in the case.

|

|

|

Load the remaining coupler with the 2 pins and springs and place it on top of the cross as shown. Don't

forget the remaining washer (I have in the distant past and had to dis-assemble the case again to put them in).

|

|

|

The sidegear and shim are mounted....

|

|

|

...followed by the case half. Align the case halves with the index drill marks as circled in yellow.

|

|

|

Flip it over and insert the 8 long bolts. Only the 4 spiders remain indicating I probably put it together right :)

|

|

|

Tighten the 8 bolts, in a cross pattern, to 45~50 ft/lb. Loctite is not needed (the factory didn't use it either).

|

|

|

I sometimes get a little carried away with the anti-seize.

|

|

|

Carefully align the bearing cap and snug the 2 bolts. I slowly snug the bolt on each side while tapping the cap with a hammer.

I feel this vibrational shock better aligns the split threads and allows me to fully tighten the bearing caps BEFORE actually setting the

wheel adjuster to its proper rotation. Repeat this on the other side also.

|

|

|

Final tighten the 4 bolts to 75 ft/lb.

|

|

|

I made up this simple adjustable spanner wrench with 2 pieces of steel. The wheels did turn easily even with the cap bolts

torqued to spec.

|

|

|

The wheels are incrementally turned on both sides until the marks line up.

|

|

|

I knew at the beginning that I had .010" backlash and, as expected, I have the same BL as before. This "specialized tool"

is not needed if the marks made in the wheels are properly re-aligned.

|

|

|

Last step- red Loctite is preferred here and 10 ft/lb. Done. ZUK

|

|