|

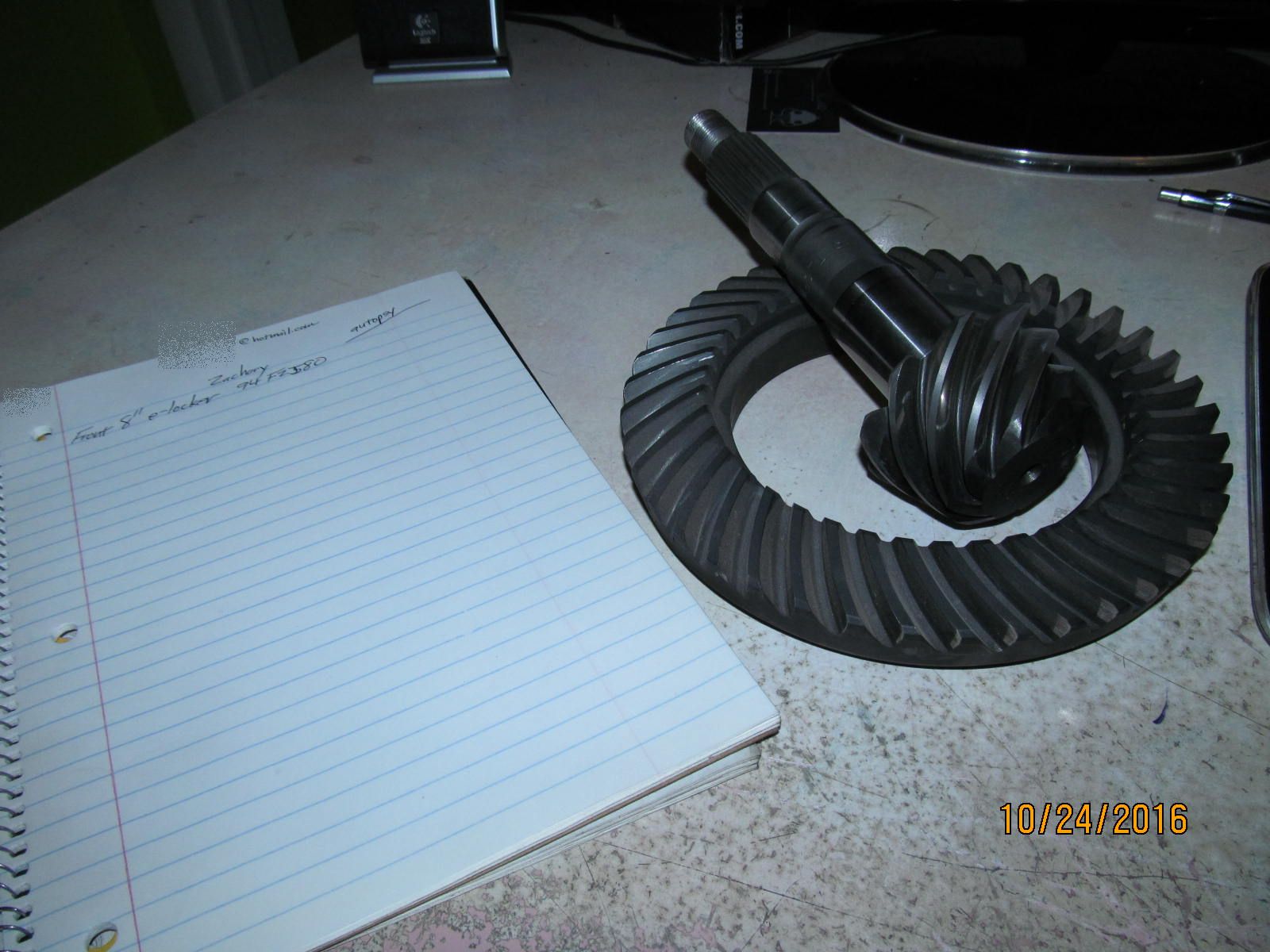

Destroyed front pinion on Zachary's 94 FZJ80

|

|

(53 BIG pics loading)

|

|

NOV 17 2016

|

|

|

Zachary's front 8" diff in his 94 FZJ80 finally gave up the ghost as he put it. He said it was

loudly knocking/pinging and sometimes making BANG sounds.

|

|

|

|

|

This double box arrived to me. That's a good 410 take-out that will be installed for Zach.

|

|

|

|

|

.........................

|

|

|

|

|

Pretty good job of cushioning the 3rd.

|

|

|

|

|

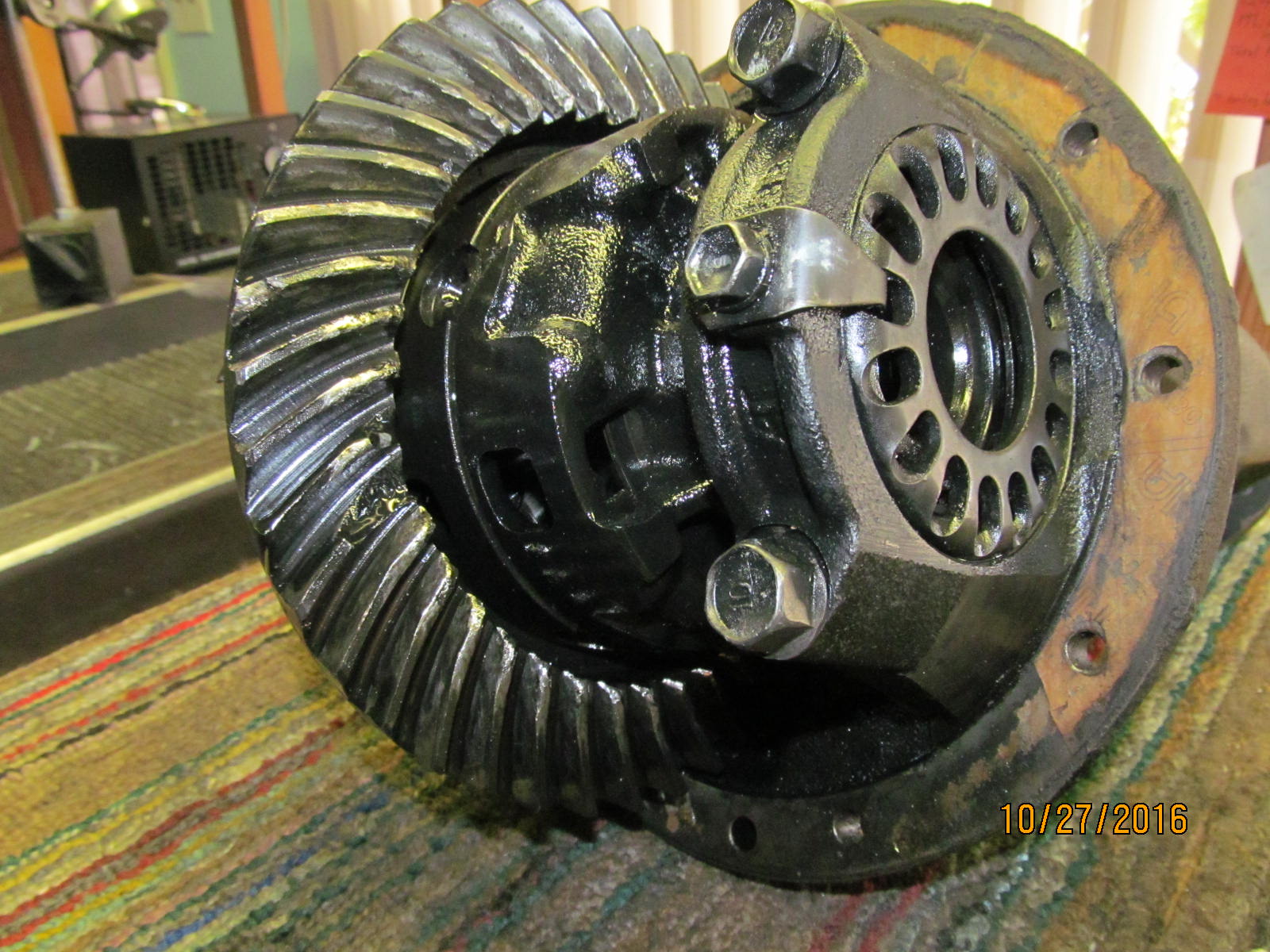

Elocker high pinion 3rd is a little dirty and will fix that shortly.

|

|

|

|

|

Ring teeth are hammered. Will also clean the gasket surface like new.

|

|

|

|

|

Pinion teeth have been nuked.

|

|

|

|

|

............................

|

|

|

|

|

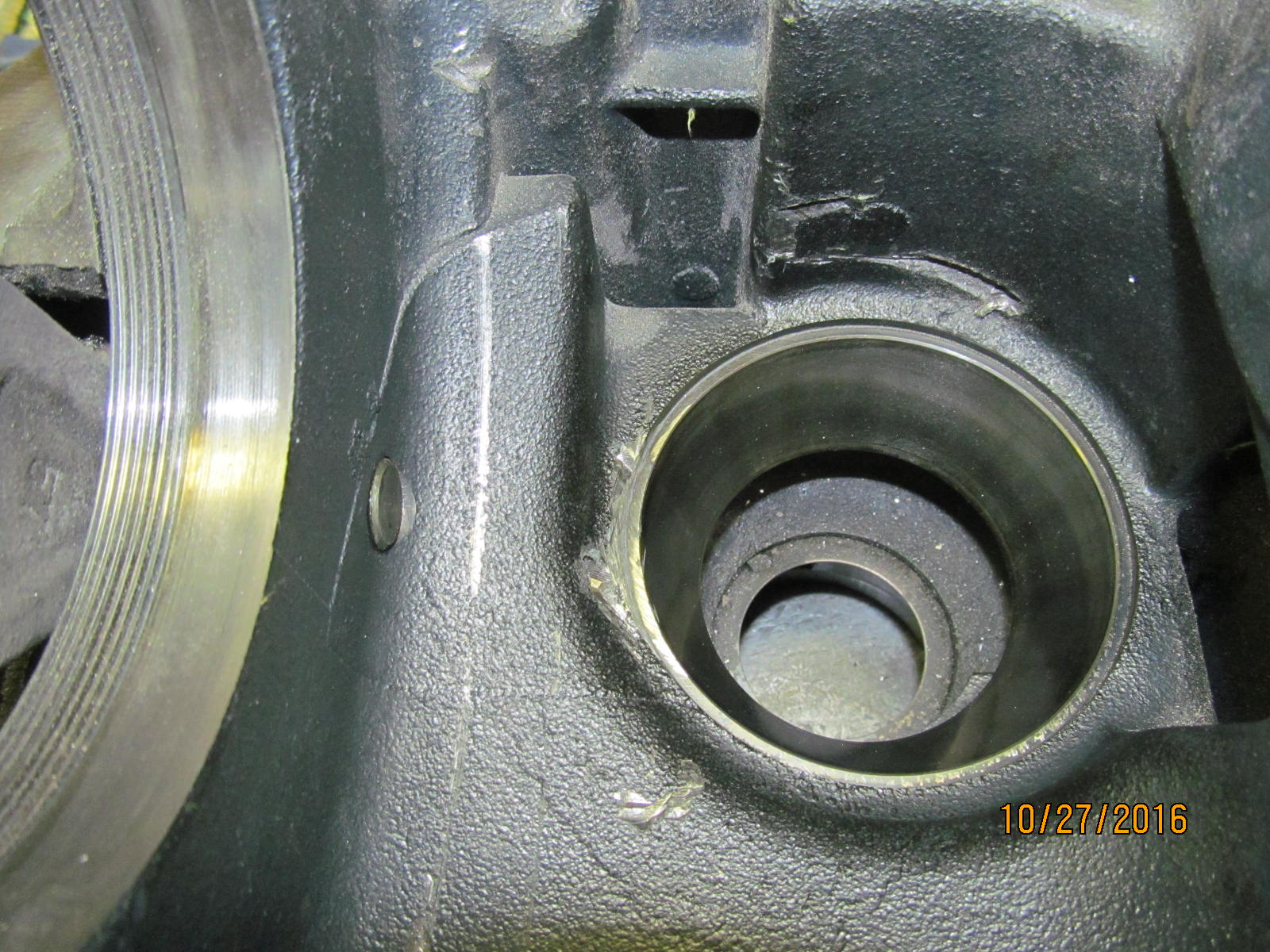

Flange is removed and pinion pressed out.

|

|

|

|

|

Seal was removed and all the rubber materials were "brittlized".

|

|

|

|

Cleaned up the soft rubber has been transformed into a hard brittle plastic. There must have

been extreme heat to do this.

|

|

|

|

|

The pinion probably was approaching red hot and that made the teeth soft.

|

|

|

|

A smaller sized set of front tires was run for a period of time and he figures that was probably

the cause due to the transfer case viscous coupler does not take kindly to the difference

in driveshaft speeds.

|

|

|

|

|

Some good scars/gouges just above the race.

|

|

|

|

|

The extreme heat did not get to the elocker case...sidegears and spiders turned smoothly.

|

|

|

|

|

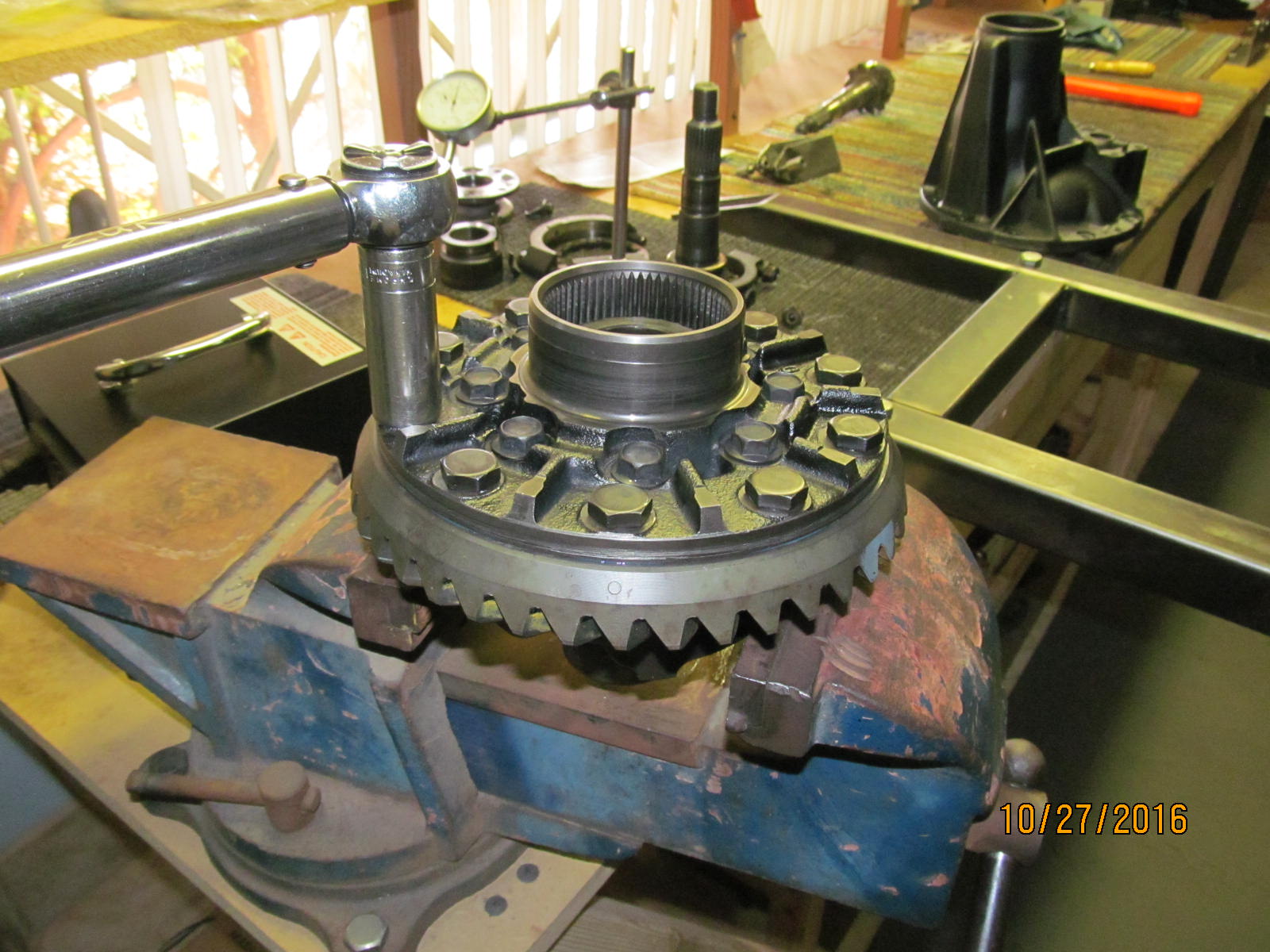

The 8 case bolts were verified to be 45 ft/lb and they all were.

|

|

|

|

|

Some cleaner/high speed wire brush/satin paint made this happen.

|

|

|

|

|

...............................

|

|

|

|

|

The good 410 reverse cut ring will be mounted....

|

|

|

|

|

...and torqued to 70 ft/lb with blue loctite.

|

|

|

|

|

A Nitro bearing kit from JustDifferentials and a Marlin eco seal.

|

|

|

|

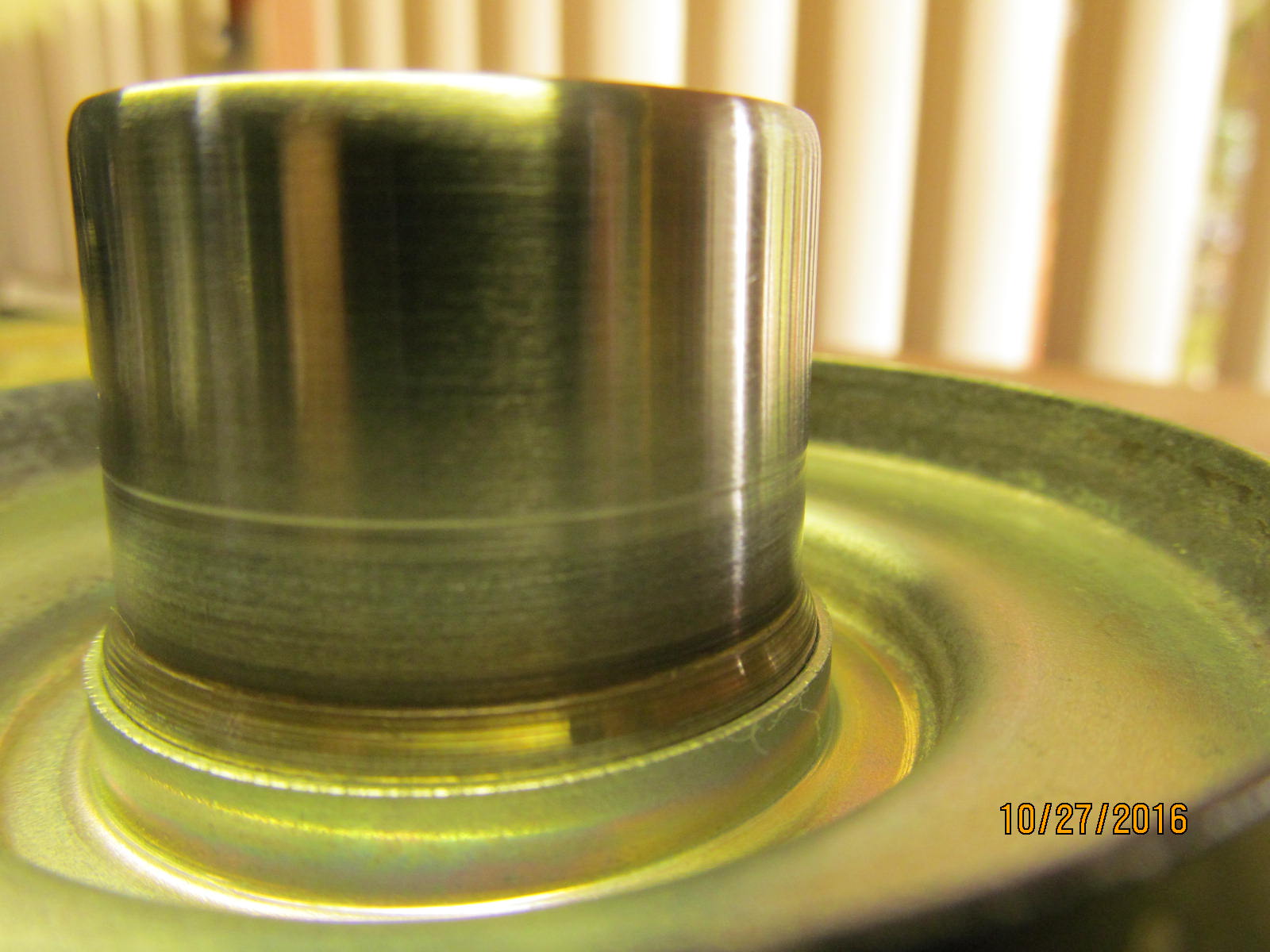

Cleaned up to the max.....there was somewhat of a groove as can be seen so I may go ahead and replace

it with a tnew triple drilled flange.

|

|

|

|

I actually think these Marlin seals are the best seal to help guarantee no gear oil leakage. I know there

has been some talk out there about leaks but there were likely other serious issues going on.

|

|

|

|

|

...............

|

|

|

|

Excuse the bottle mistake. In reality, Loctite #638 retaining compound was used on the pinion

races to firmly lock them in place.....the wrong bottle was posed in the pic.

|

|

|

|

|

Same here.....the green retaining compound was used here, too.

|

|

|

|

|

For the first pinion shim depth we will use .0795"

|

|

|

|

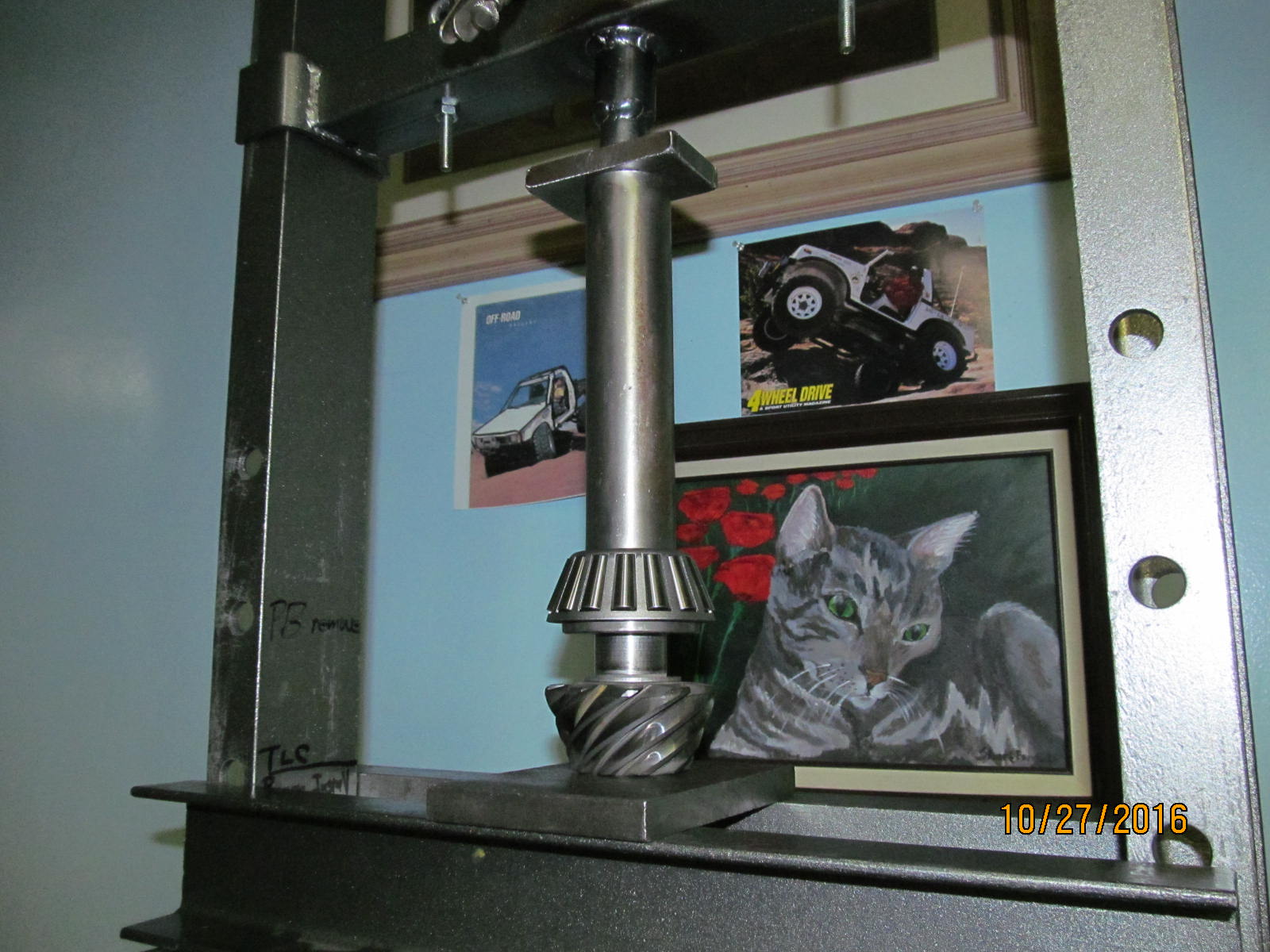

Press the new bearing on with the 12 ton. The white Yota flatbed is a 92 22re 5 speed. It was a fun build.

The white Sami was bought off the showroom floor in 1990. Moab Rim trail....the Devil's Crack.

My sister painted that kitty. That's Bullseye.

|

|

|

|

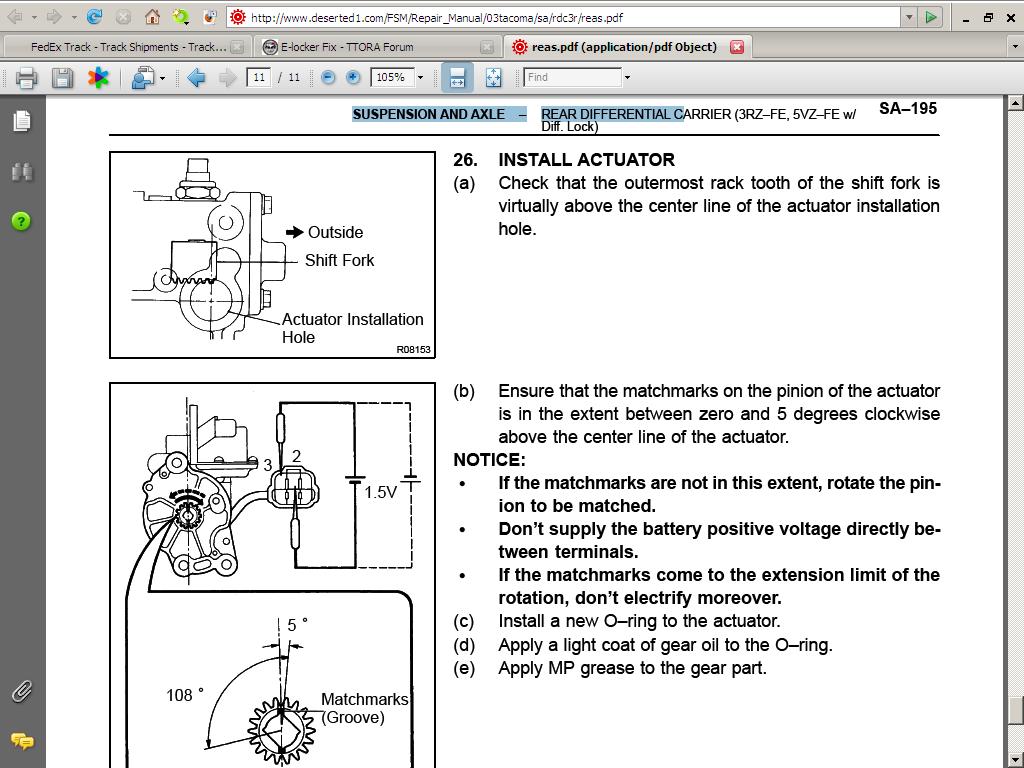

Zach also sent the e-motor with the 3rd. It was not working most of the time and all I could do was run a 1.5 volt

test and it failed....no movement noted with the battery applied to pins 2 and 3.

|

|

|

|

|

...............................

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

|

|

|

|

Pinion was loaded into the empty 3rd. For this paint test, the pinion preload does not have

to be precise.....just as long as it turns "firmly".

|

|

|

|

|

Drive side....hmmmm...a touch deeper than my taste.

|

|

|

|

|

Coast....a little deep.

|

|

|

|

|

Drive on the pinion tooth.

|

|

|

|

|

....................

|

|

|

|

|

Taking .003" off with this new .077" shim.

|

|

|

|

|

Drive. Looks good.

|

|

|

|

|

Coast deepish but good.

|

|

|

|

|

Drive.

|

|

|

|

|

....................

|

|

|

|

I would recommend a solid collar for hardcore useage. 37" tires.....double cases.....manual transmission

is the formula for a solid collar. Zach does not need one with his intended useage and an auto tranny.

Crush it is.

|

|

|

|

|

Crush is already in and the Marlin seal was tapped in place.

|

|

|

|

|

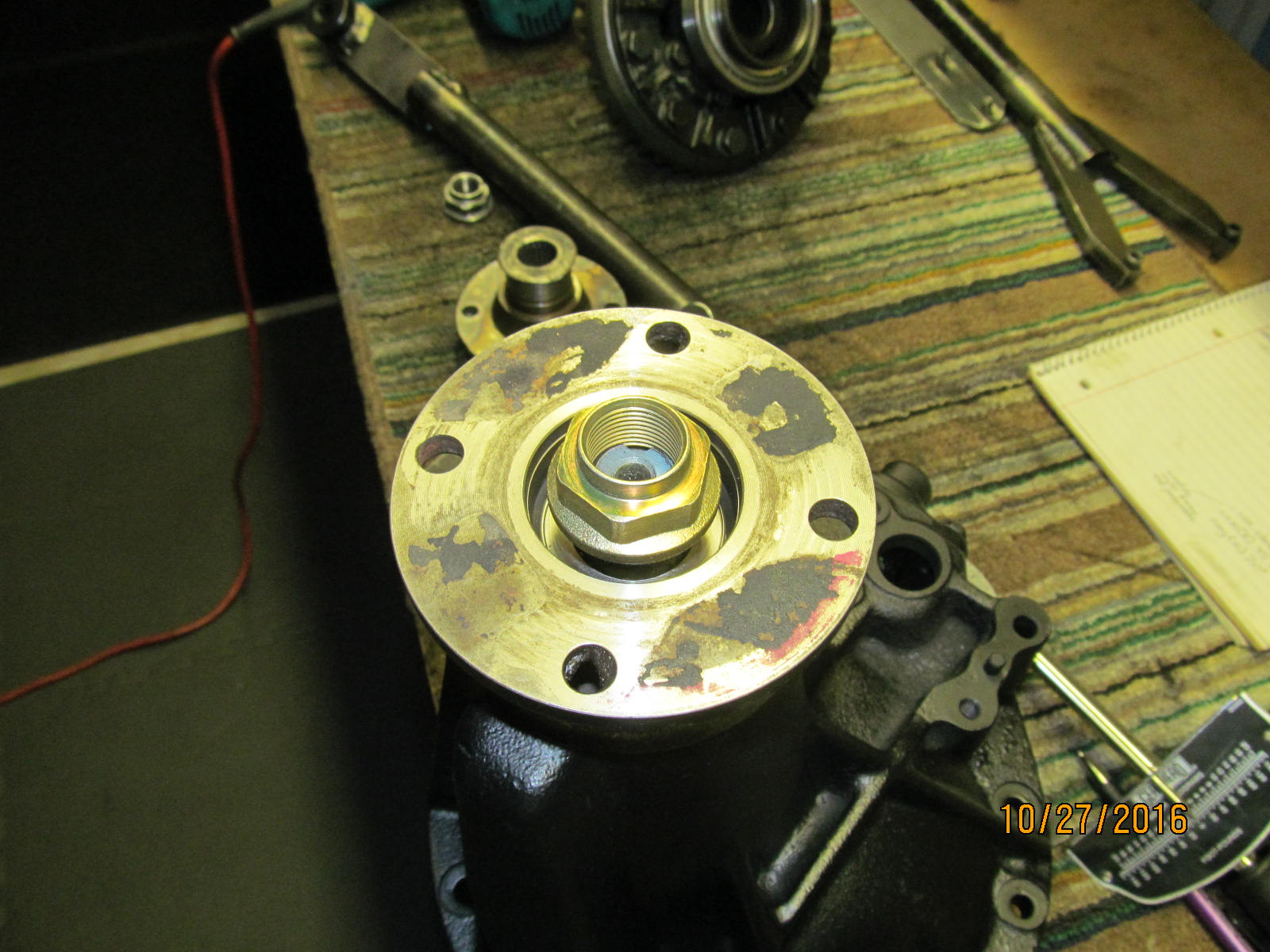

Was going to use the factory flange with a small groove but changed my mind.

|

|

|

|

|

Elected to use a new triple drilled one.

|

|

|

|

|

A nice 12 in/lb of smooth, repeatable pinion start torque noted.

|

|

|

|

|

Ding and this will not loosen on its own.

|

|

|

|

|

Loading up the elocker guts now.

|

|

|

|

|

70 ft/lb on the 4 bearing cap bolts.

|

|

|

|

|

Carrier bearing preload and backlash are "synchronized". BL checked on every other tooth.

|

|

|

|

|

The correct bottle is posing in the pic. 10 ft/lb and some blue loctite.

|

|

|

|

|

Date coded.

|

|

|

|

|

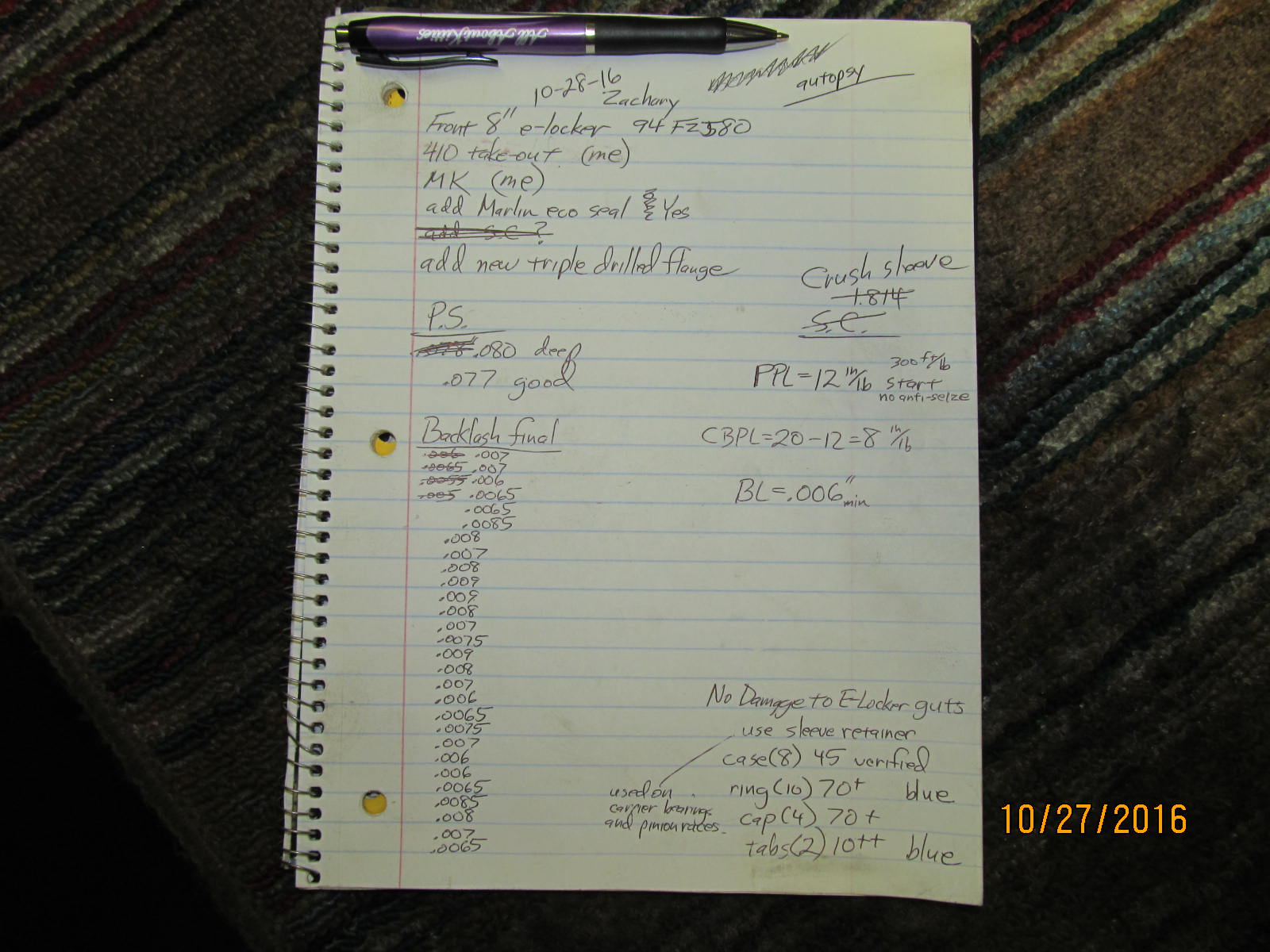

Final assembly notes.

|

|

|

|