| Justin's Eaton Elocker (14216-1) fell apart !! |

|---|

| (72 BIG pics loading) |

| Jan 19 2026 |

|

|

All 8 of the Eaton allan bolts had come loose....Can't really blame the Eaton... It's the fault of the new hire that didn't use the Loctite and didn't torque to spec. |

|---|

|

|

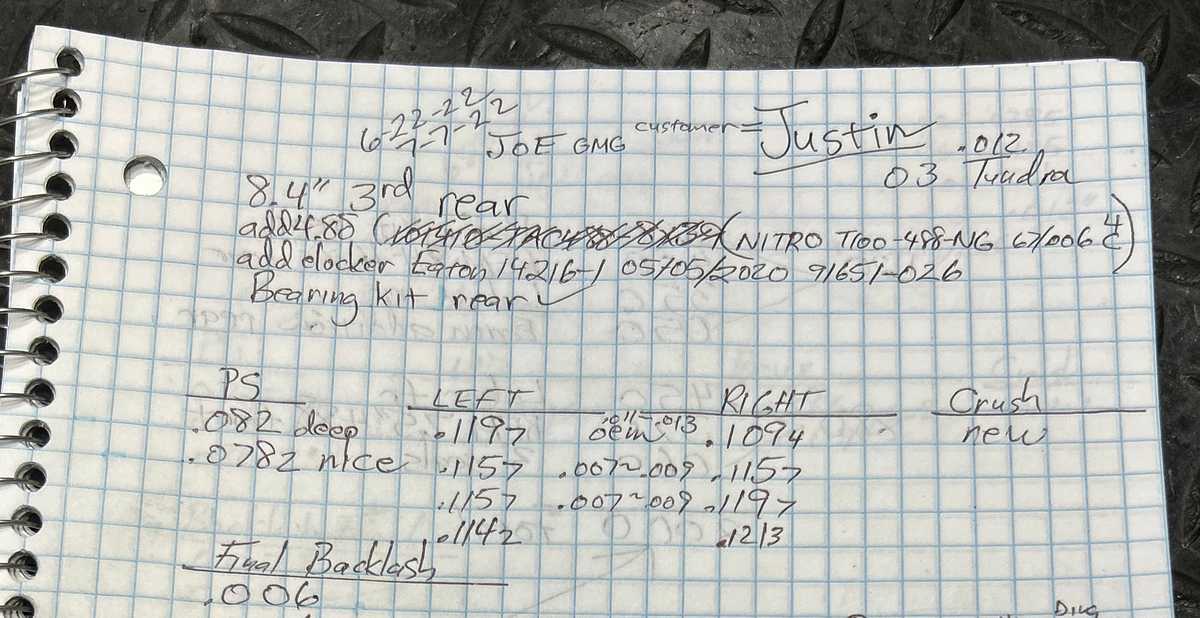

Justin's 2003 Tundra gets used. He has modified it to handle any task he needs to. In the above picture, you see a missing IFS setup. You see a custom Diamond housing with an 8.4 center section and FJ80 outers. The rear is the factory 8.4 housing with stock factory axles. The engine is the 4.7L V8 with factory auto. Torque is multiplied by a Northwest Fab double box. It's triple sticked...he can run both transfercases in low range. Elockers front and rear with 4.88 Nitro gears. |

|

|

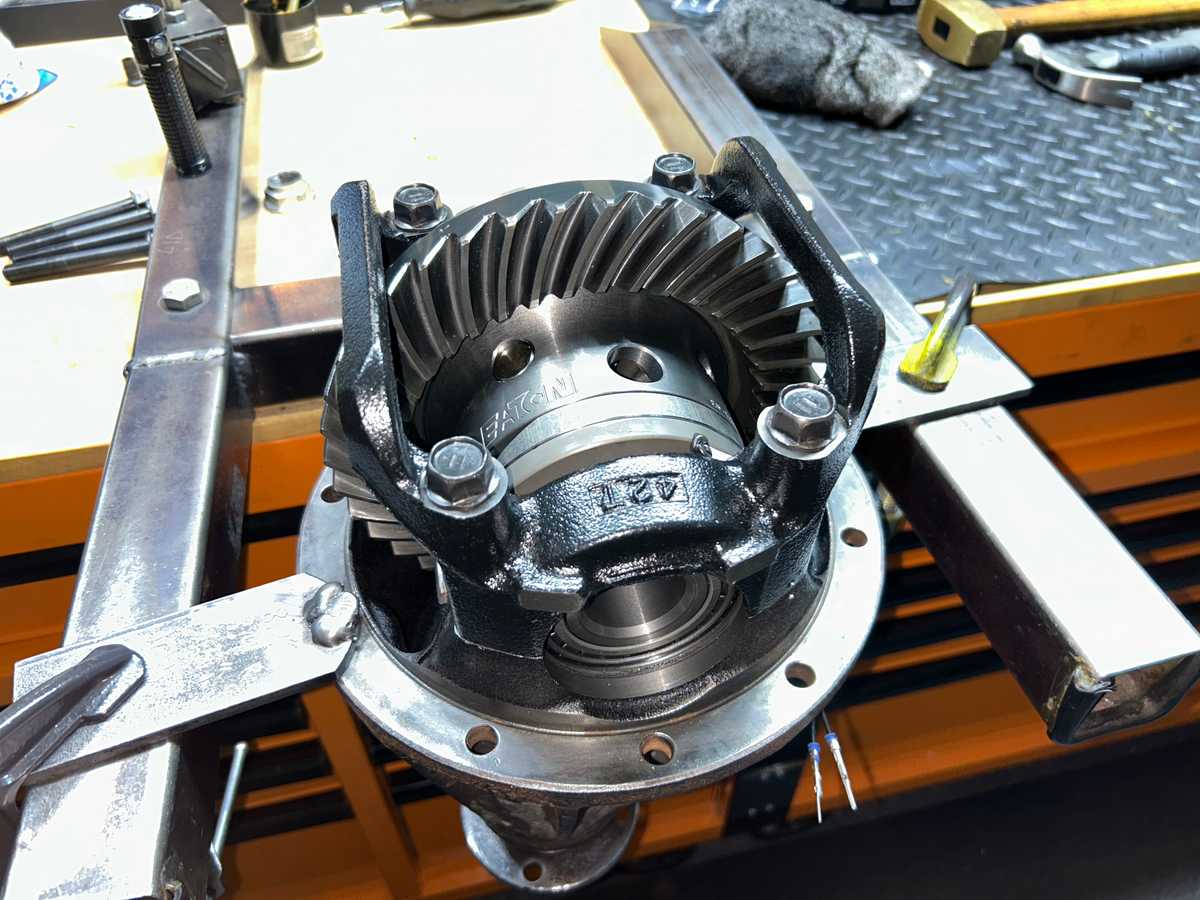

Shown above is the 8.4" rear 3rd that Justin shuttled up to me with the NEW Eaton elocker Lately, the rear 8.4" has been making bad noises. The oil was full of metal mush and 4 allen bolts were in with the drained oil. |

|

| Super polished gears with an install I did 3.5 years ago on July 7 2022. |

|

|

Locating my old notes, I see that the 14216-1 Eaton elocker was manufactured on May 5, 2020. May of 2020....That was when Covid19 was the the big thing. |

|

| The elocker is all jacked. |

|

| That pin should never be there..... |

|

| ...Neither should that crack in the ramp ring. |

|

| Jacked. |

|

| OOPS...there's the issue. The allen bolts had backed out. |

|

| Some of the holes are empty. |

|

| ................................................................................... |

|

| Rotating the center carrier shows that they were all loose...all 8 of them. |

|

|

Those 8 allen bolts were tearing up the inside of the cross-brace. Now removing it to inspect. |

|

| Looks good from this angle. |

|

| Boy oh boy....this thing is gouged bad. |

|

| bad. |

|

| I'm not going to use this...it's going in the trash. |

|

| Close examination of the threads shows not even a trace of "loctite". |

|

| =============================================================== |

|

| All parts have been pre-cleaned before taking pics. Too bad this 3rd is damaged this much. |

|

|

The cracked ramp ring again. This is a very strong locker but ALL lockers will self destruct when factory bolts mysteriously wiggle loose. |

|

| Another shot. Not even a trace of high strength Loctite was found on the threaded regions. |

|

|

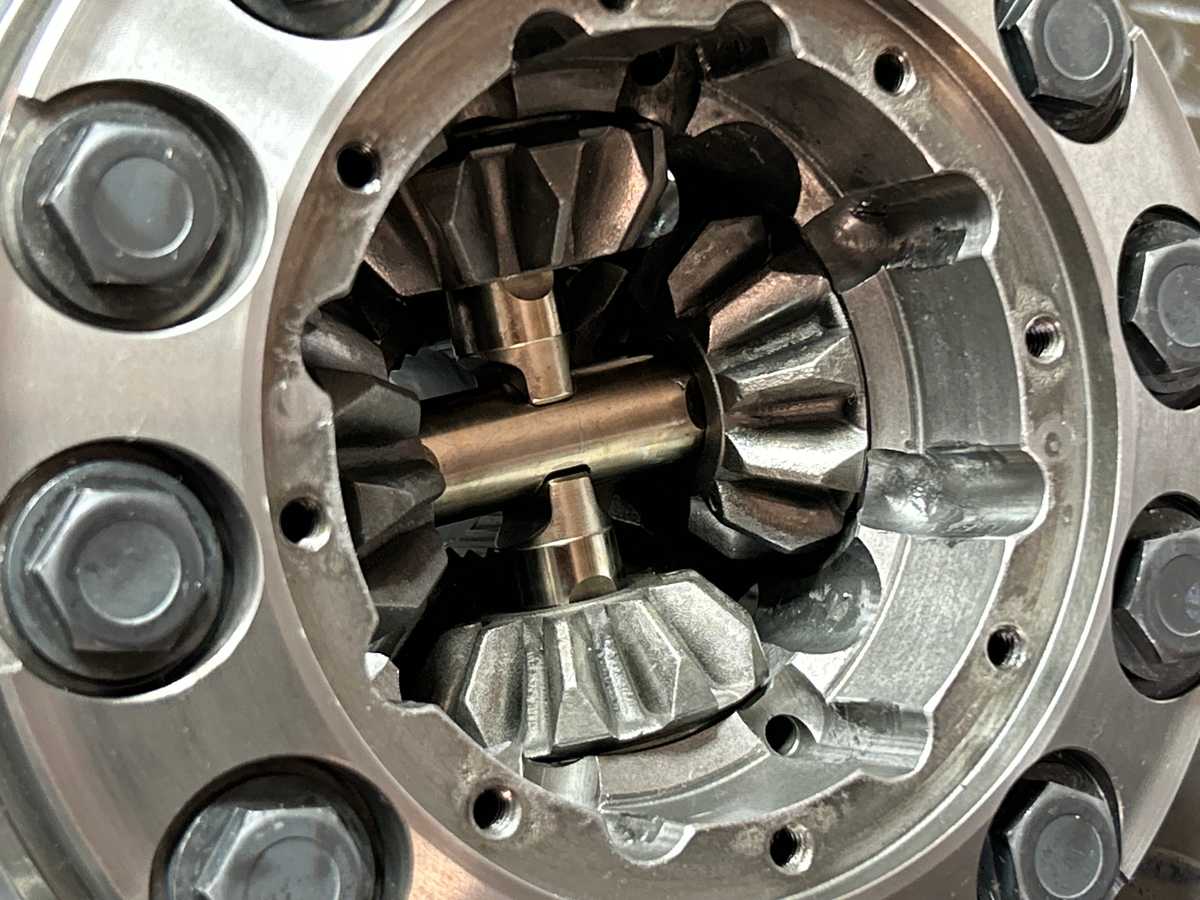

So the end cap was ready to fall off so let's peek inside and see how it looks. Looks undamaged. Spiders and sidegears ok. |

|

|

As I mentioned earlier, I blasted away 99% of the sludge using starting fluid. Looks good inside. |

|

| Nice workmanship inside. |

|

|

So I temporarily re-assembled it and thoroughly wiped clean the teeth for inspection. No unusual trauma and cracks, |

|

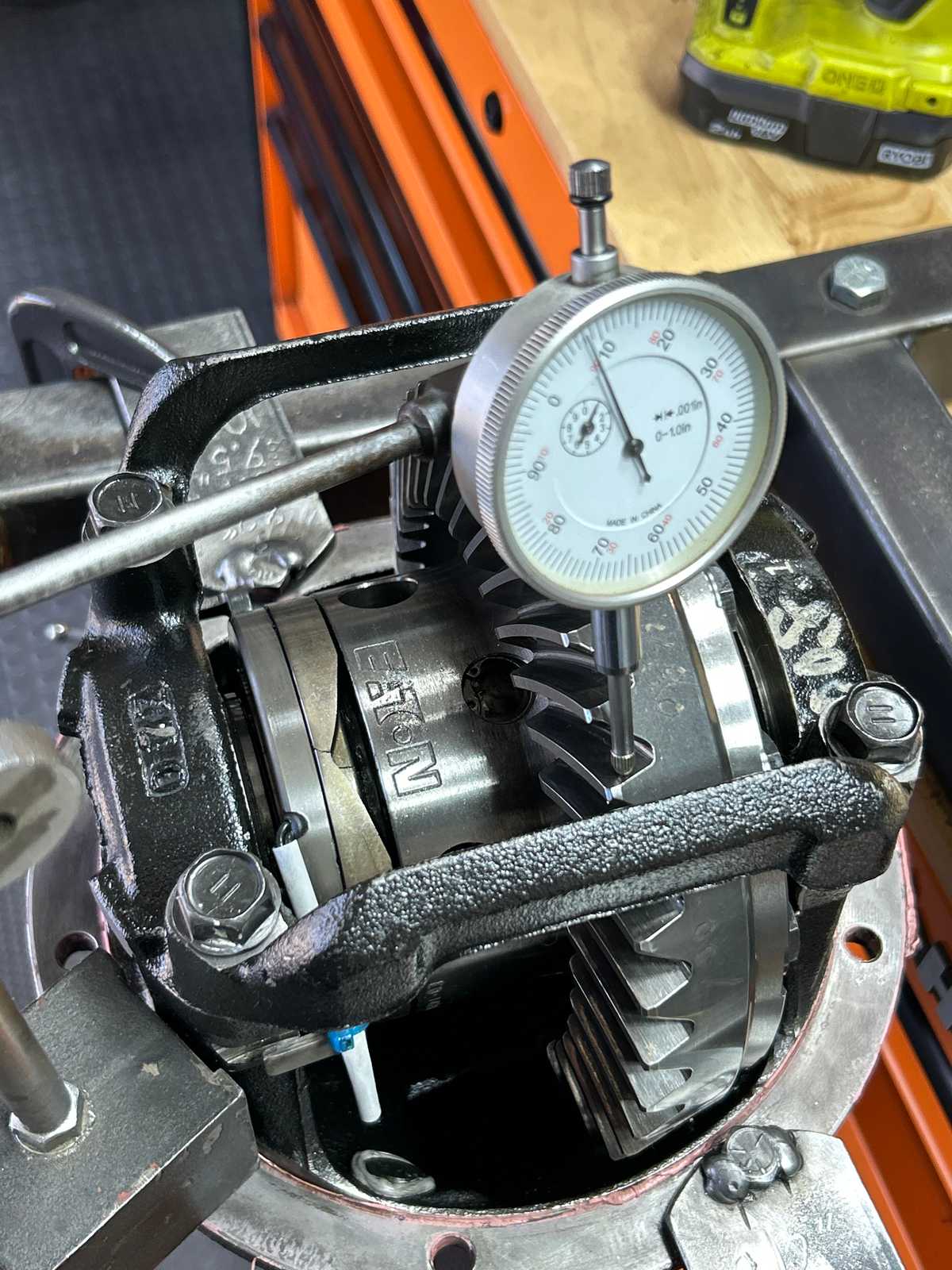

| Put the center carrier back into the 3rd and did some backlash checks....all was good there. |

|

| Pattern check...Driveside looks very good. |

|

| Coast looks excellent. |

|

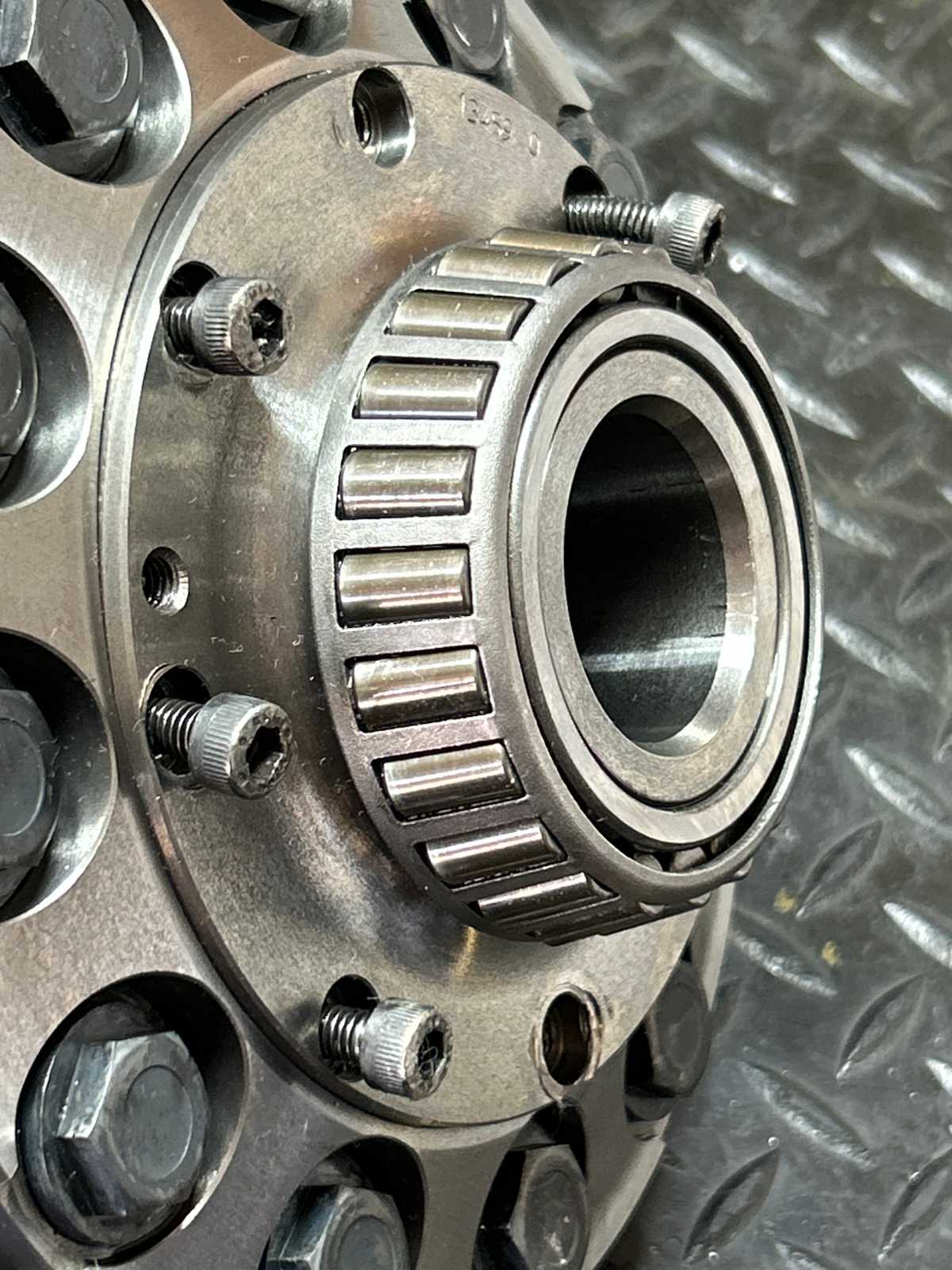

| Genuine factory bearings will soon go in. |

|

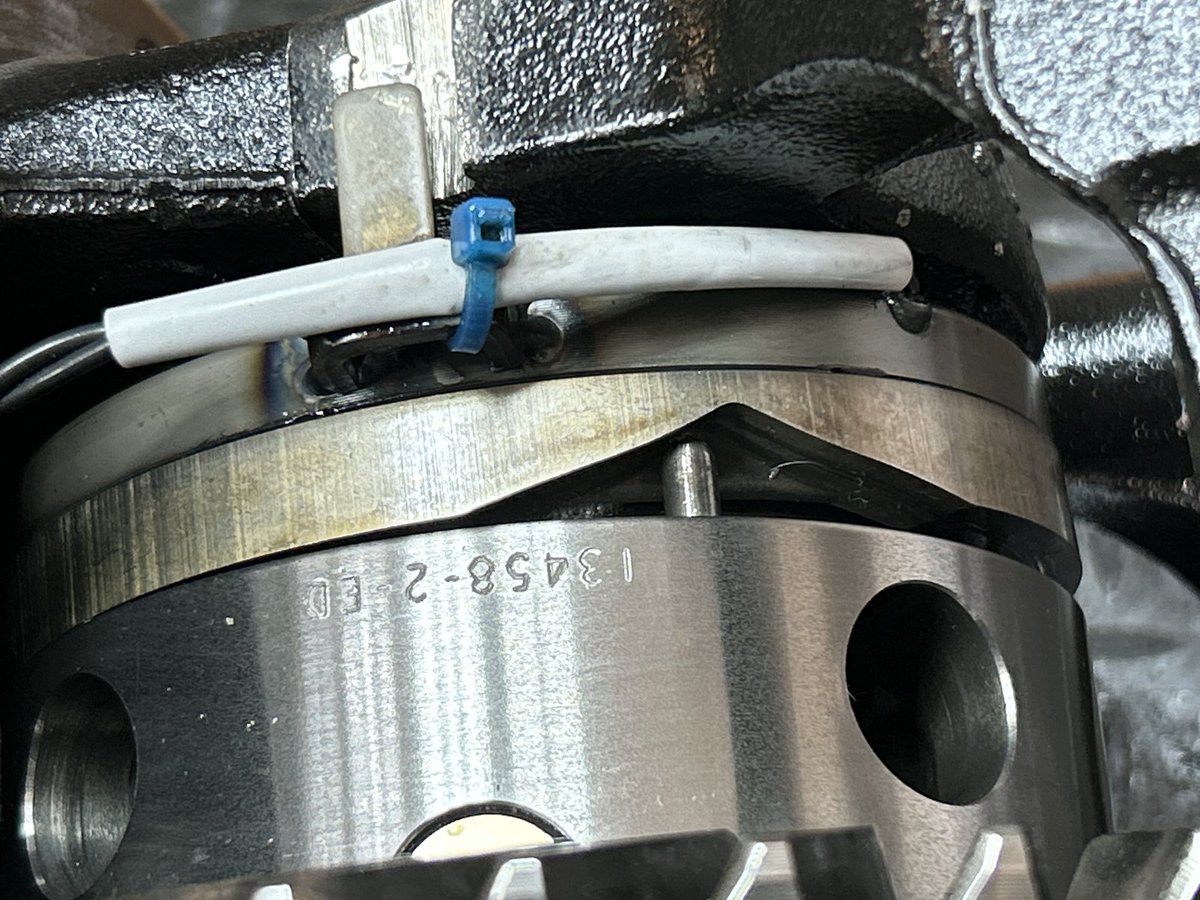

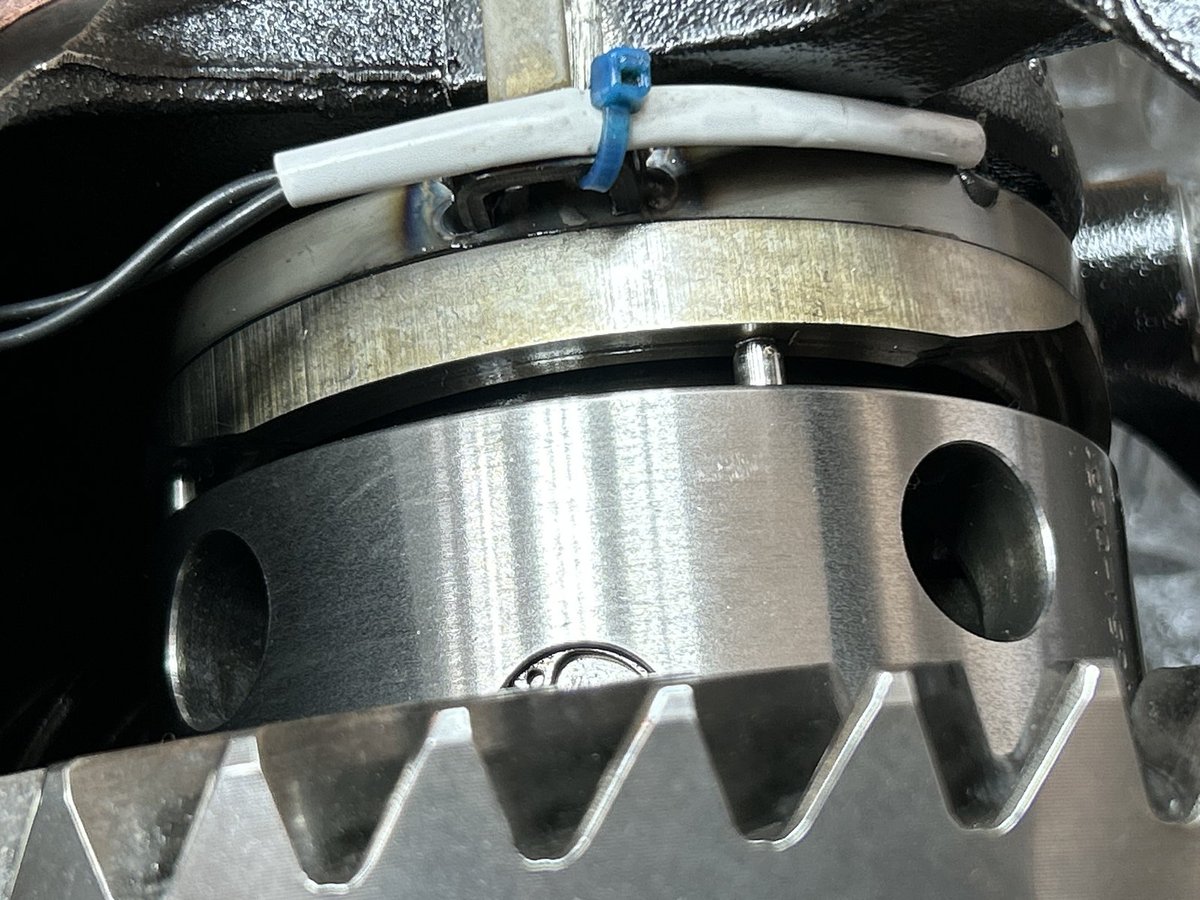

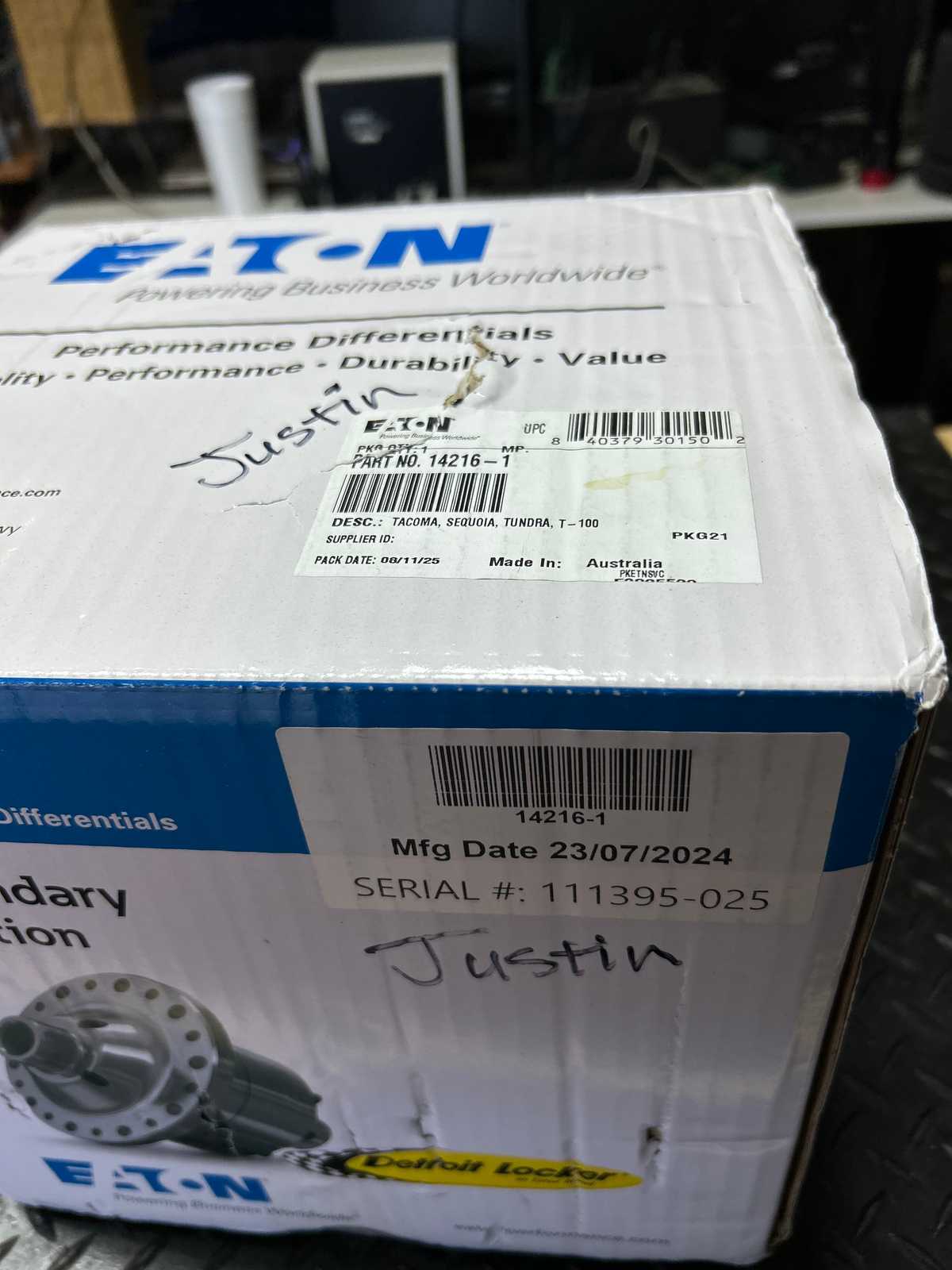

| Here is the new elocker that Justin brought me...made in July of 2024. |

|

|

I did open up the orange bag for this snapshot but the rest was undisturbed. Eaton needs better packers. |

|

| Only thing missing was the instruction booklet and that is available online. |

|

|

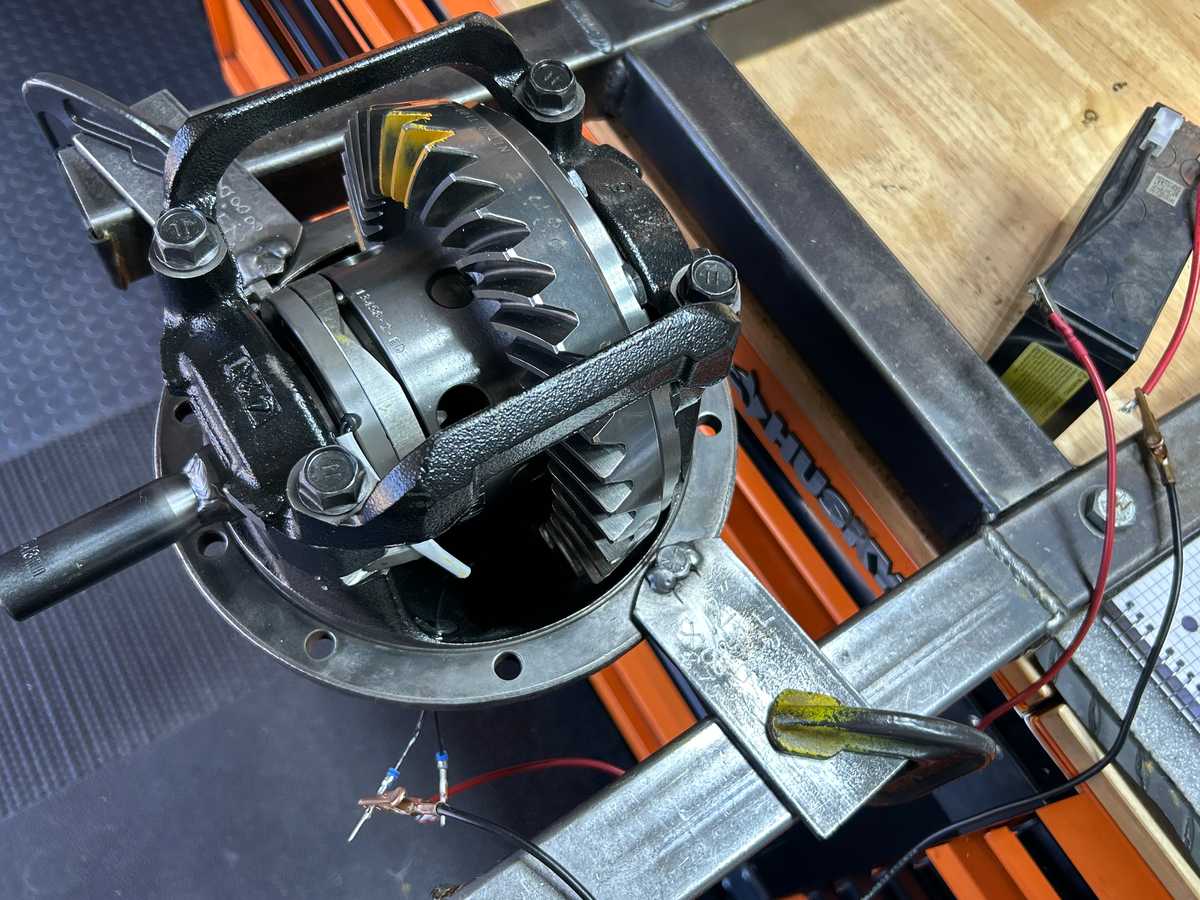

The super polished ring gear has been swapped over to the new locker... red loctite and 92 ft/lb on all 12 ring gear bolts. New carrier bearings are now pressed on. |

|

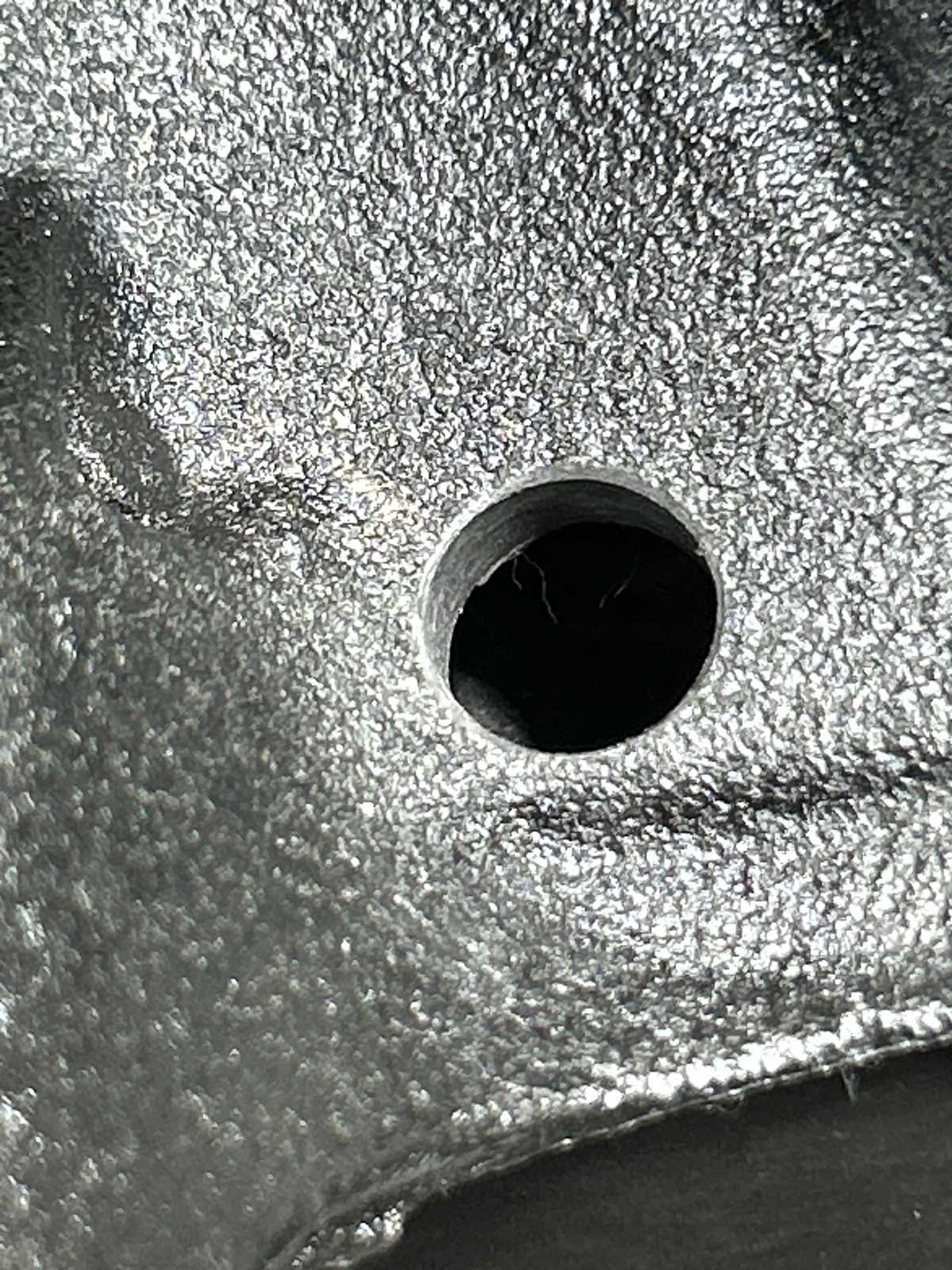

| The .480" grommet hole can now be drilled. |

|

| The new outer race can go in.... |

|

| This is what a .480" drilled hole looks like over-macro'd :) |

|

| Inside is lightly chamferred to help the rubber grommet push thru. |

|

| The large inner pinion race can now be pressed in with the .078" washer plate. |

|

| That 50 cent bubble has been so helpful in keeping things level. |

|

| Seated down 100%. |

|

| --------------------------------------------------------------- |

|

| Pressing the new pinion bearing on with the 12ton Harborfreight press. |

|

| No crush sleeve yet. |

|

| Now fully assembled and let's do a paint check. |

|

| Drive good. |

|

| Coast good. |

|

| Now to grind the slots into the side of the braces for the stop tabs. |

|

| I mark each side to give me a starting point for the cutting wheel... |

|

| My cordless Ryobi does the job just fine. |

|

| --------------------------------------------------------------- |

|

| Out of focus....but these get tapped in as the LAST step...not now. |

|

|

Better focus...these tabs will tap in nicely. This type of capture will keep the stop tabs from spreading out. |

|

|

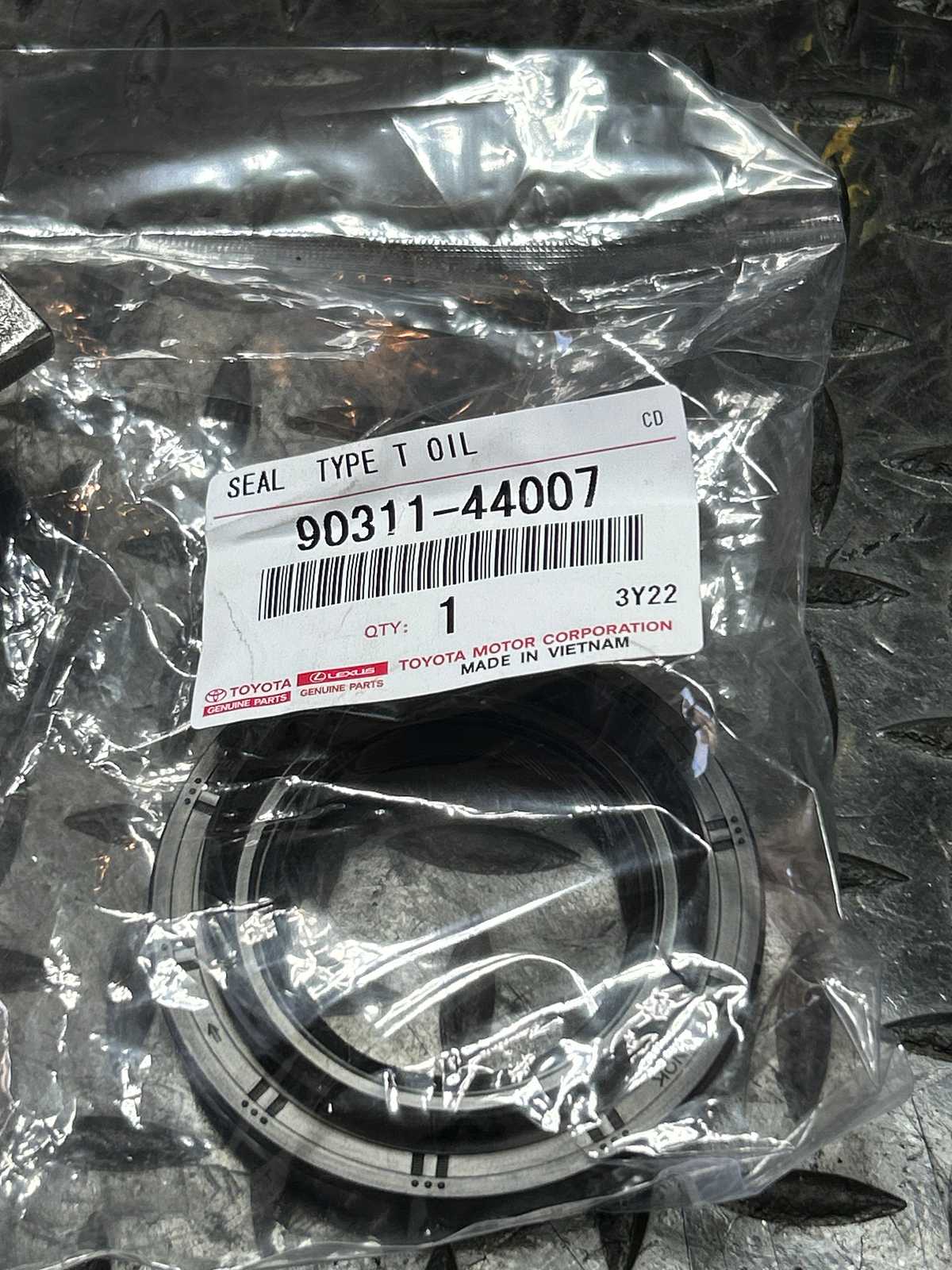

The 3rd was dis-assembled one last time to put the crush sleeve in... Now the new seal. |

|

| --------------------------------------------------------------- |

|

| Crush the sleeve until the pinion preload reaches about 13 inch/pounds. Done on this end. |

|

|

Carrier bearing washer plates are tapped in. These tapped in very tight. Justin is getting EXTRA CBPL. |

|

| Now the stop tabs do get tapped in. |

|

| -------------------------------------------------------------- |

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|

| `````````````````````````````````````````````````````````````` |

|

|

The 4 long bolts are snugged up with the electric impact and then torqued down to 83 ft/lb each. |

|

| AN RTV sealant is smeared on the rubber grommet to help it slide thru the hole. |

|

| ................................................................................... |

|

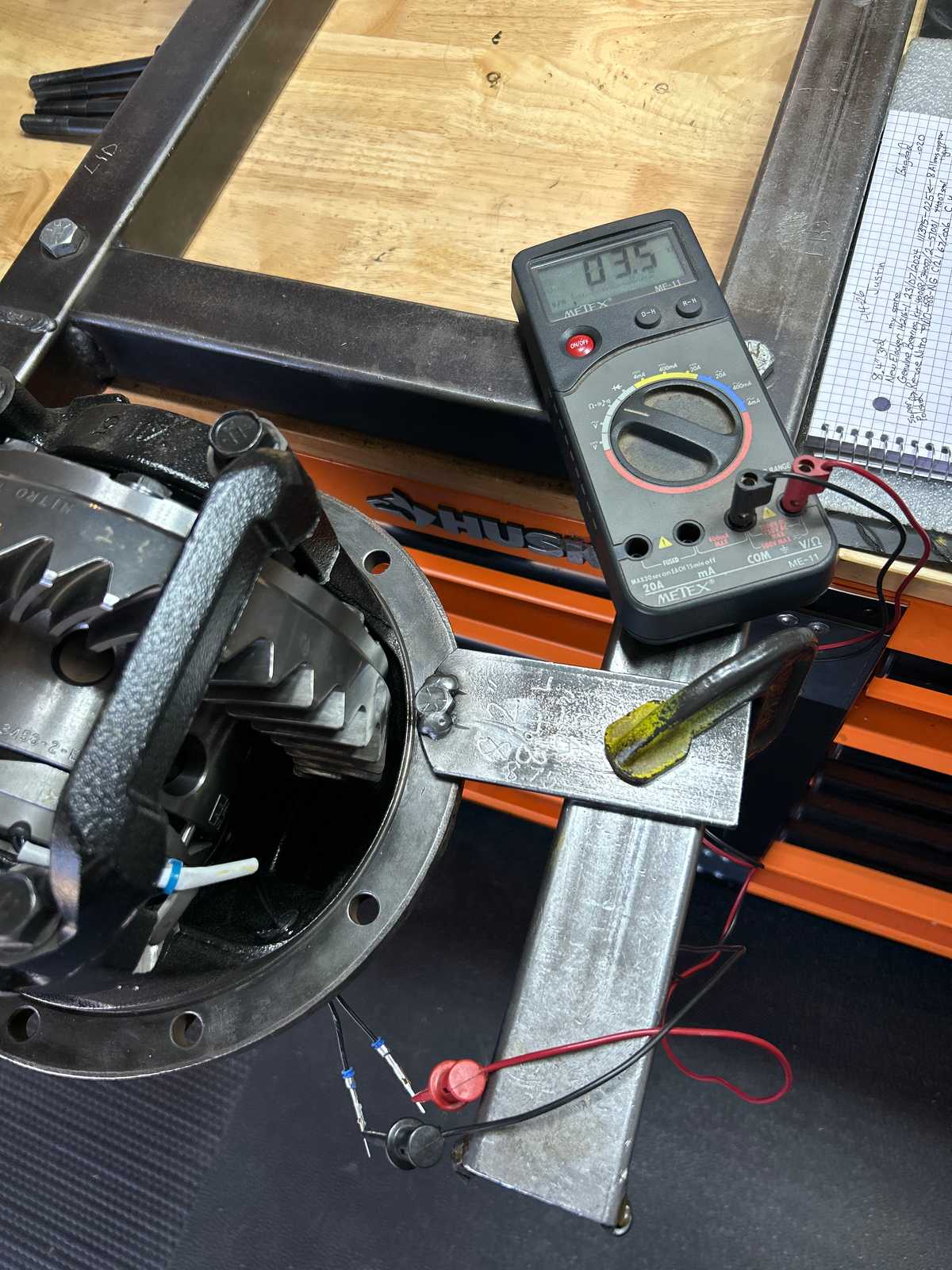

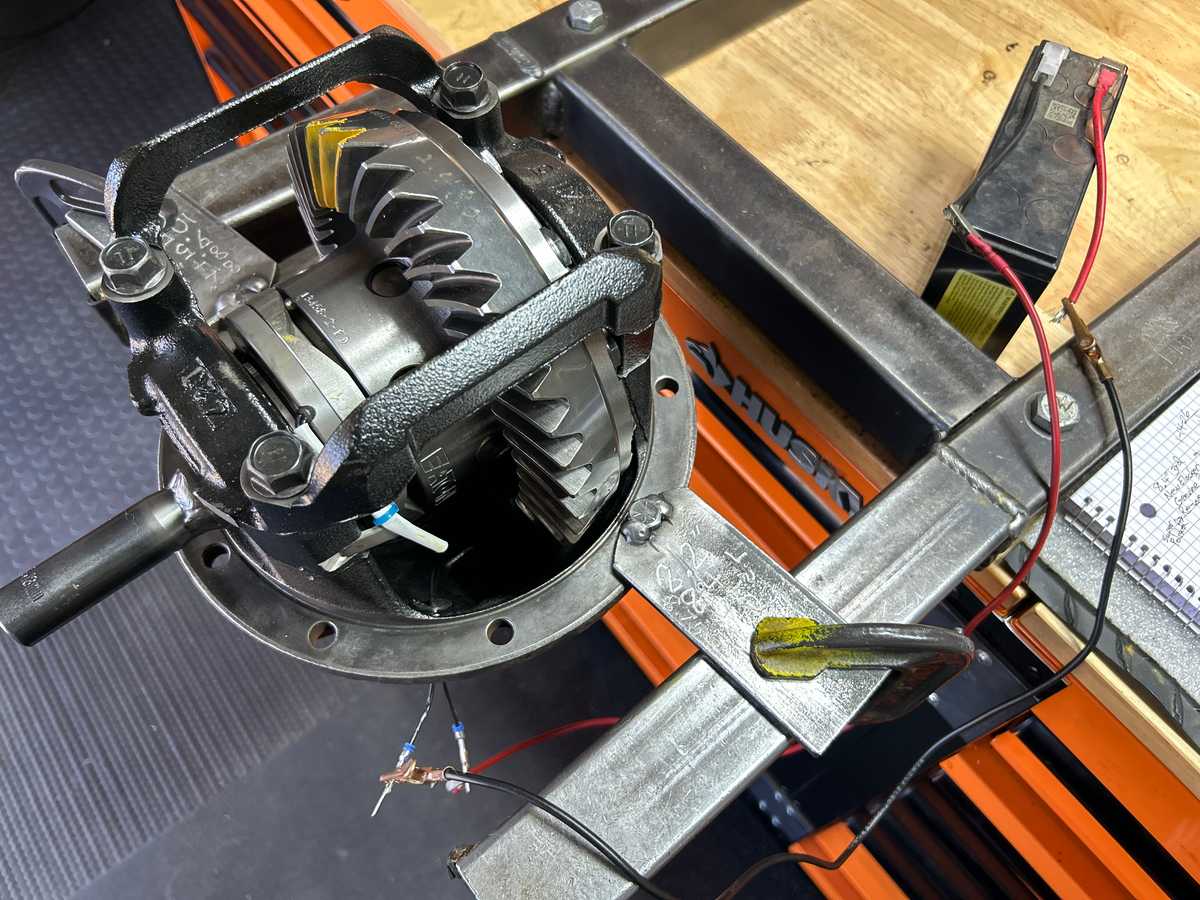

| 2 items that I use to check the elocker function. |

|

| Now measuring 3.5 ohms on the magnetic coil. Good. |

|

| 12 volt check..... |

|

| 12 volts = PASS. |

|

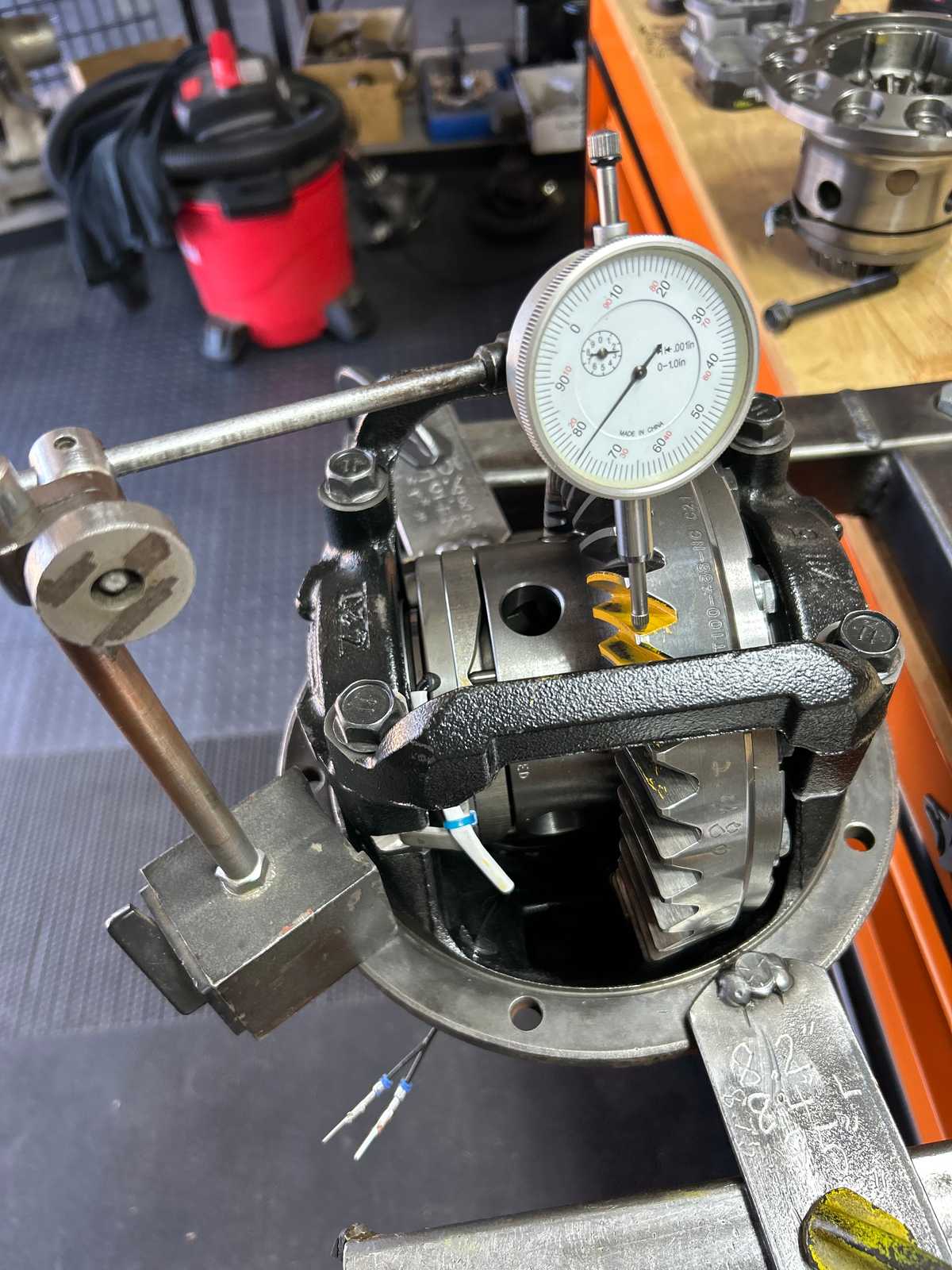

| Recording backlash on every other tooth. |

|

| Final notes. |

|

| ................................................................................... |

|

| ................................................................................... |