Even during a proper slow break-in of new rough gears the contact tooth surface will experienced a "trauma"

and there will be some micro pitting damage. The gears may last a long time....or they might not. In a nutshell,

grinding 2 teeth together and tearing the tooling marks off is not going to leave the micro-surface looking pretty afterwards.

Shown above is one that did not last.

steel, ceramic or glass media pneumatically propelled at relatively high velocities. These shot particles

create a series of overlapping dimples on the material's surface which put the upper layers of the material

into compression, and help to prevent fatigue failure in the material. It could be argued that shot peening

is "as good" and possibly better than REM super polish. The benefits are very low friction which means diff

temps will be very cool, much better fatigue resistance to breakage, and no 500 mile break-in.

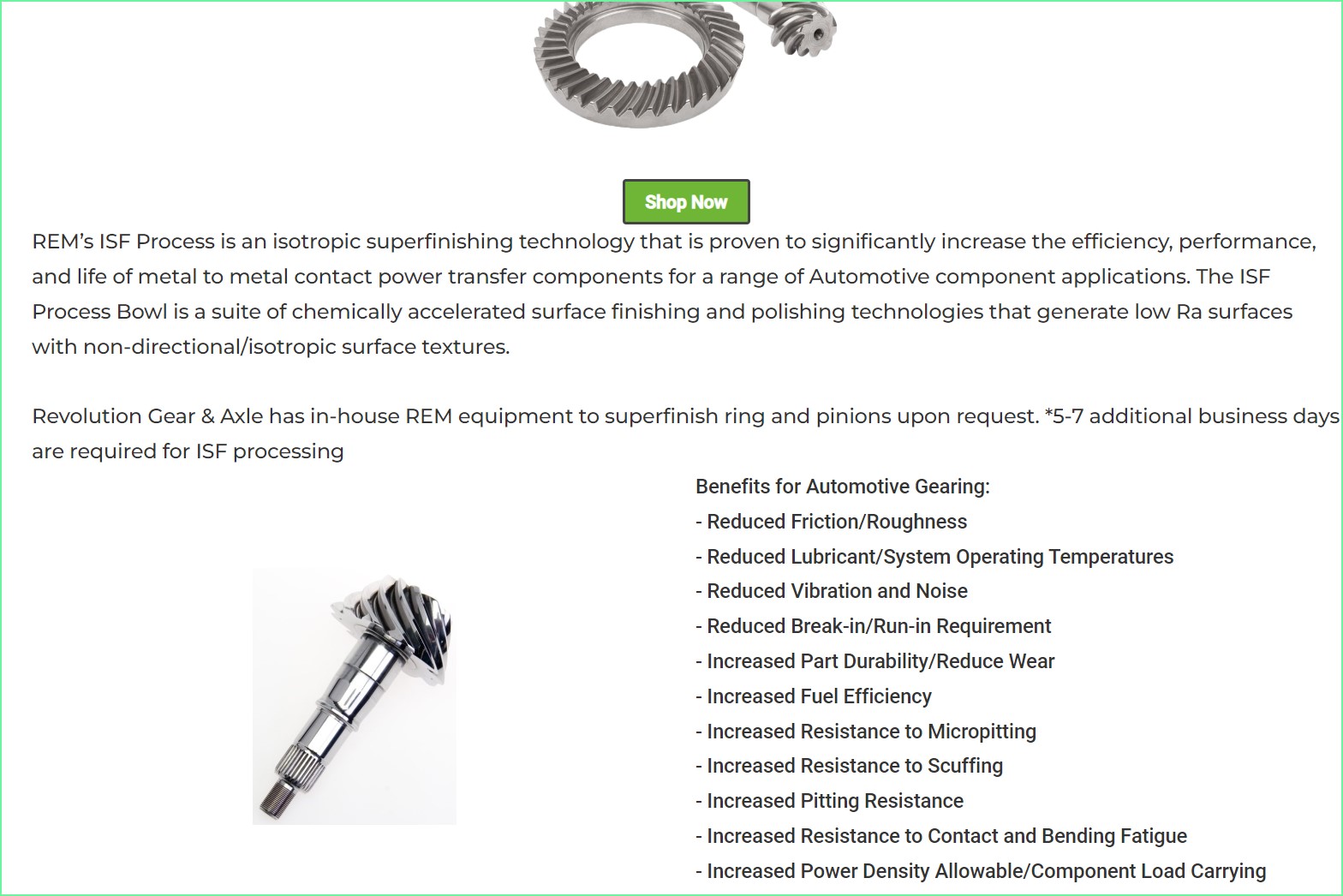

REM treatment results in a smoother surface. The end result is less friction, less heat, and less wear. Any machined part has

high and low areas left over from machining, grinding, etc. Those high spots become the initial contact points which in turn can

become localized hot spots. Those localized hot spots can take the temper out of the heat treated area of the surface and then

become a pit. REM greatly reduces that possibility. Cool clean oil and no 500 mile break-in are the main benefits.

about WPC

They offer revolutiongear which is a high quality gear and they are one of the few online stores that offer an optional super

polish service. The service must be requested over the phone and is only $100 per ring/pinion at this time.

A second place is located right in the Phoenix Valley in Arizona....Ayers Gear and Machine 702 N 37th Dr. Phoenix, AZ 85009

623-934-6913 Ask for Parker

Rumor has it that they now have a shot peen option....inquire within.

A 3rd place is New England Gear Polish located in Connecticut. 860-807-5513

They do an excellent job on the shine.

To summarize....has anybody noticed that Ford Chevy Nissan Toyota and the whole rest of them that they make

no mention of a slow careful 500 mile break-in?.....no changing the gear oil after 500 miles. Why is that?

It's because all of their ring/pinions are done inhouse with an upgraded shot peen similar to the shot peen

that RPC offers. It's an ultra-fine media that is blasted at higher speeds of about 800 mph and results in

all the benfits of normal shot peen plus more. The actual process is all computer controlled and automated

so it takes a couple minutes per ring/pinion and it's done.

Your guess is as good as mine why the aftermarket does not do the same......instead, they churn out ring/pinions

that are 90% done and expect the customer to do the last 10%....and hope that the gears survive.

REM super polish takes about 5 hours....5 ring/pinions can be done at the same time. That's 1 hour per ring/pinion.

That's too much time for the big companies on the assembly line. But perfectly fine for us gear installers/shops

that want gears that are actually finished.

It will be a good gear install if you have a good installer that has good gears to work with. :)