|

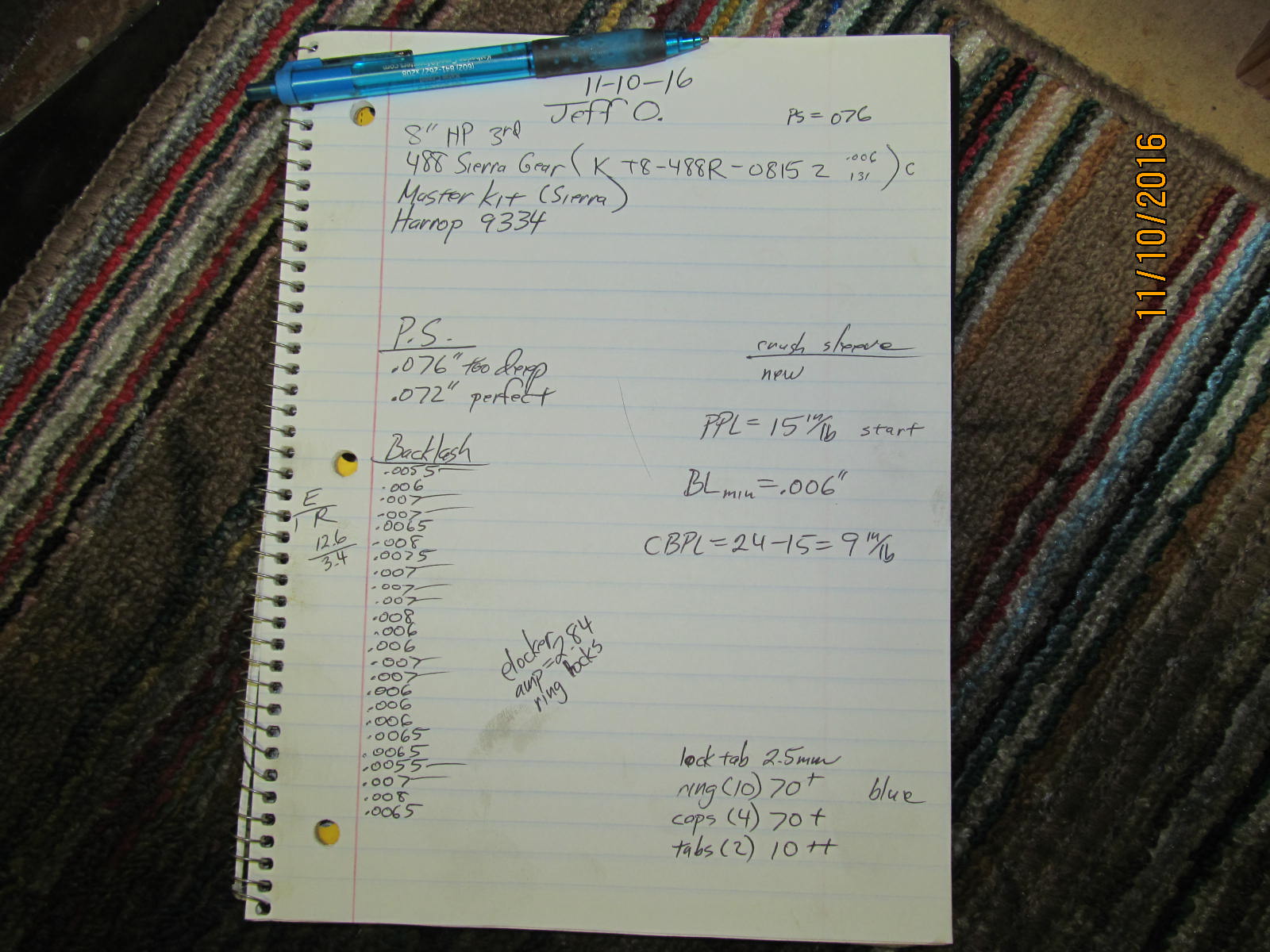

Harrop elockers and Sierra 488 Gears for Jeff's FJ80

|

|

(48 BIG pics loading)

|

|

FEB 17 2017

|

|

|

|

Jeff from Texas has a well maintained FZJ80 with some excellent armor plating.

|

|

|

|

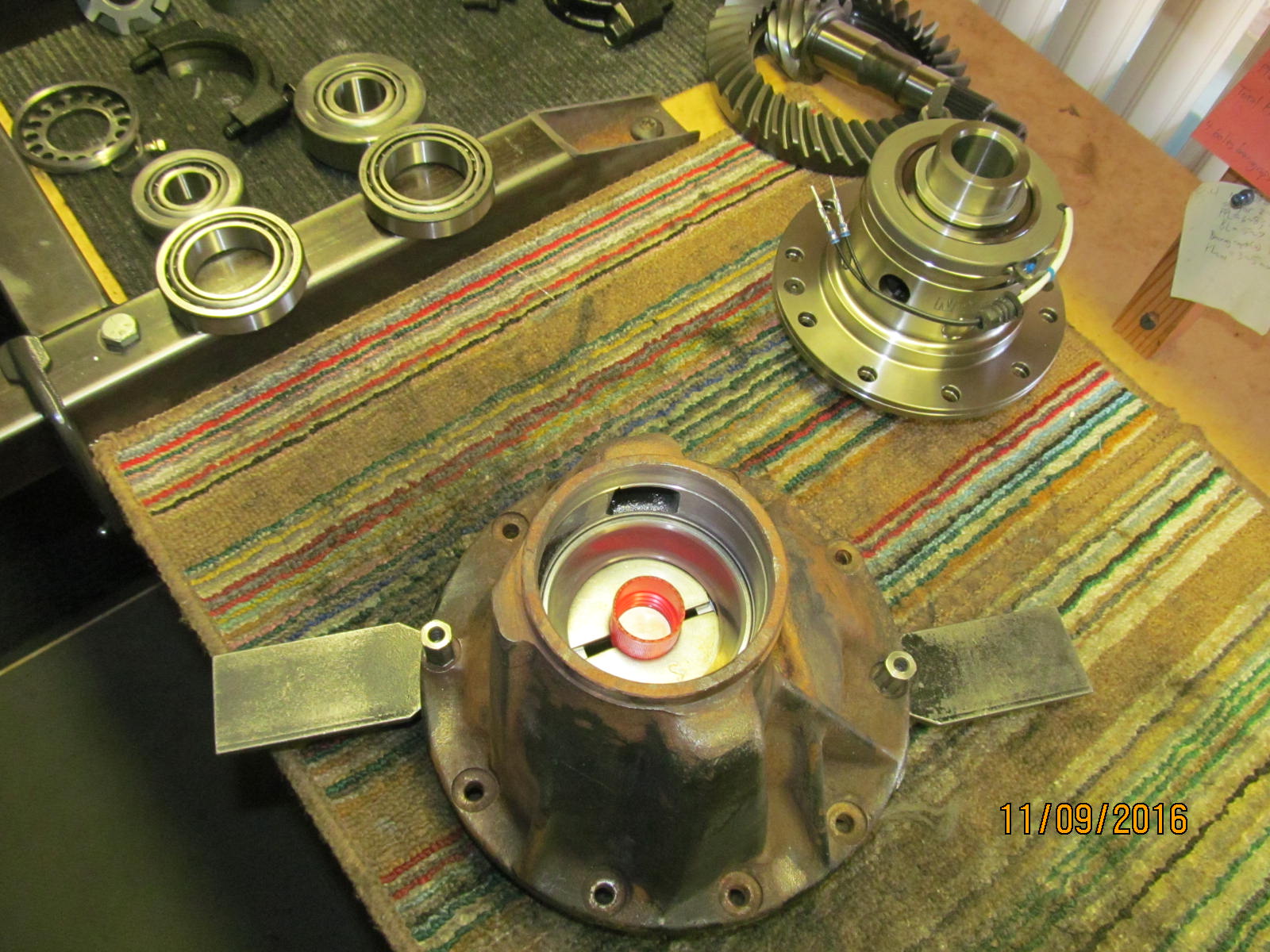

Jeff also sent the master kits and Sierra ring/pinions.

Two Harrops....one for the rear 9.5" and one for the front high pinion 8".

Harrops can be purchased from yotalockers.com

|

|

|

|

The high pinion front will be done first.

Here's the link to the BIG 9.5" rear Harrop install.

|

|

|

|

|

The front 8" Harrop # 9334 will work for the low or high pinion 8" 3rds.....including rear V6 8" 3rds.

|

|

|

|

The Sierra master install kit has the usual stuff....4 bearings...crush...

10 bolts...nut....shims....rtv...brush and paint.

|

|

|

|

|

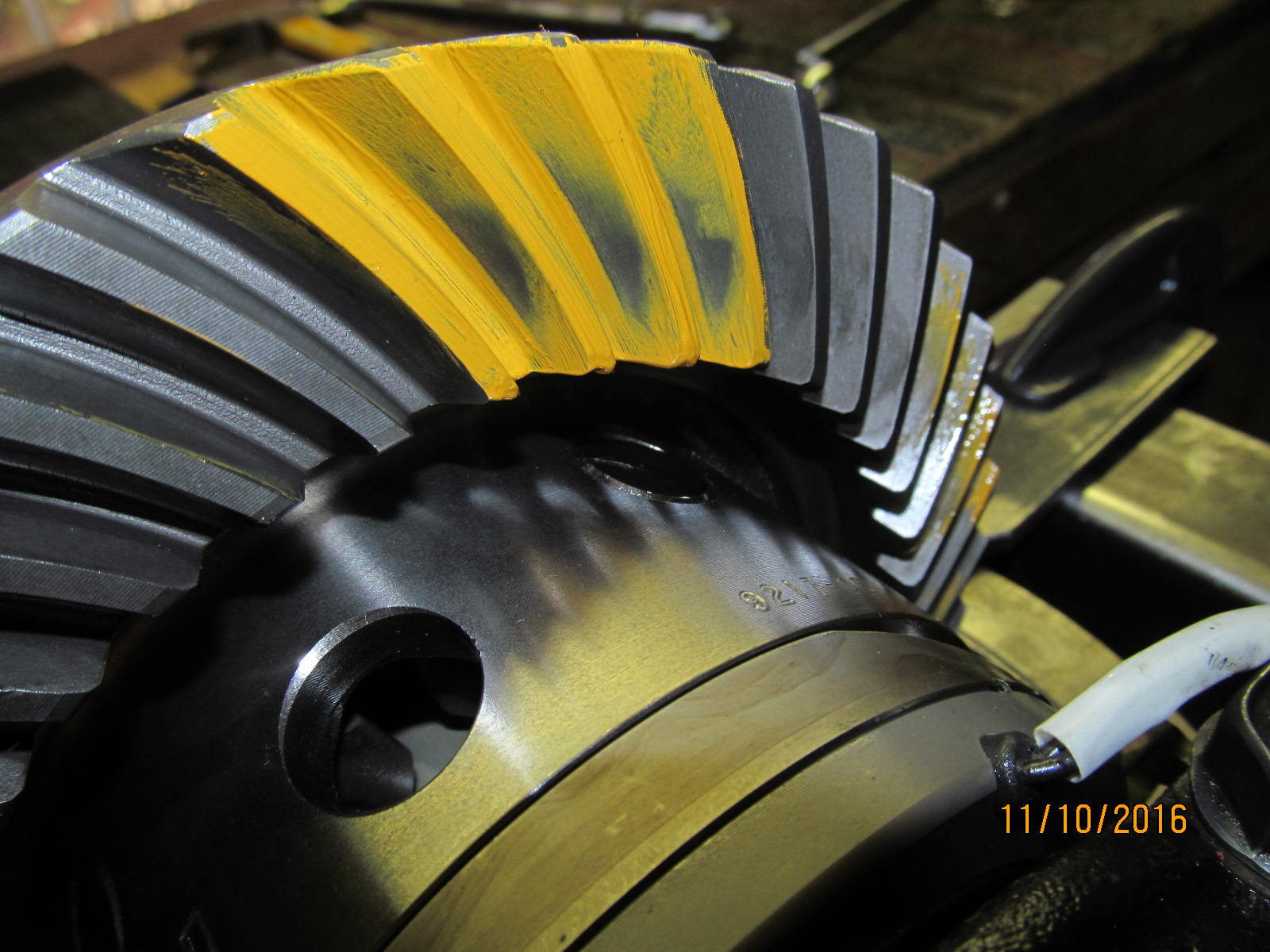

I like the finish on the ring gear.

|

|

|

|

The 9334 Harrop. Well machined and a proven engagement mechanism. This particular elocker

probably fits the most models of trucks and landcruisers out there.....fits the rear and

front of 79~85 trucks/Runners....the rears of all the 86~95 pickups/Runners both 4 cyl

and V6....etc etc etc.

I believe the Harrops can be used in a standard 4cyl or V6 3rd and replace the OEM factory

8" e-locker with minor tweaks to the e-locker housing.

|

|

|

|

|

Parts are organized.....it's all there. Crush sleeve for this one....no solid collar is needed.

|

|

|

|

The teardown begins. Notice how clean the 3rd appears. Jeff sent it pretty clean overall

but I used the high speed wire wheel to remove all traces of paper gasket.

|

|

|

|

|

Whizz the nut off, remove flange, and push out the pinion as shown here.

|

|

|

|

|

The small outer race can easily be removed with 2 half washers and a plastic bottle cap.

|

|

|

|

|

Push it out with probably less than 500 pounds effective force.

|

|

|

|

|

The oil retainer is undamaged.

|

|

|

|

|

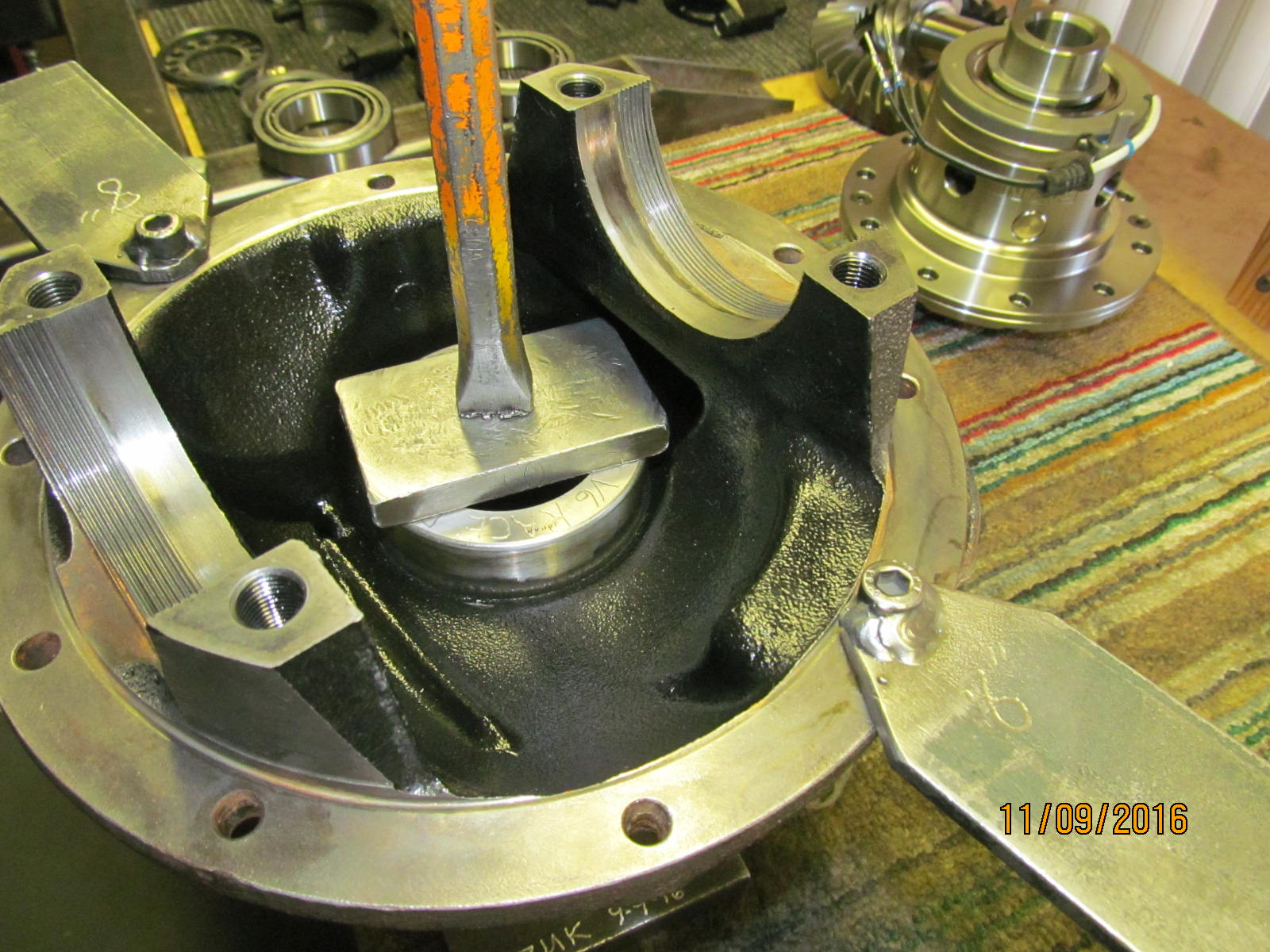

The larger inner race can be removed with a flat chisel and hammer.

|

|

|

|

|

The new race is hammered in with 360 degree support so that the new race is not damaged.

|

|

|

|

|

Tap tap tap and the new outer race is in.

|

|

|

|

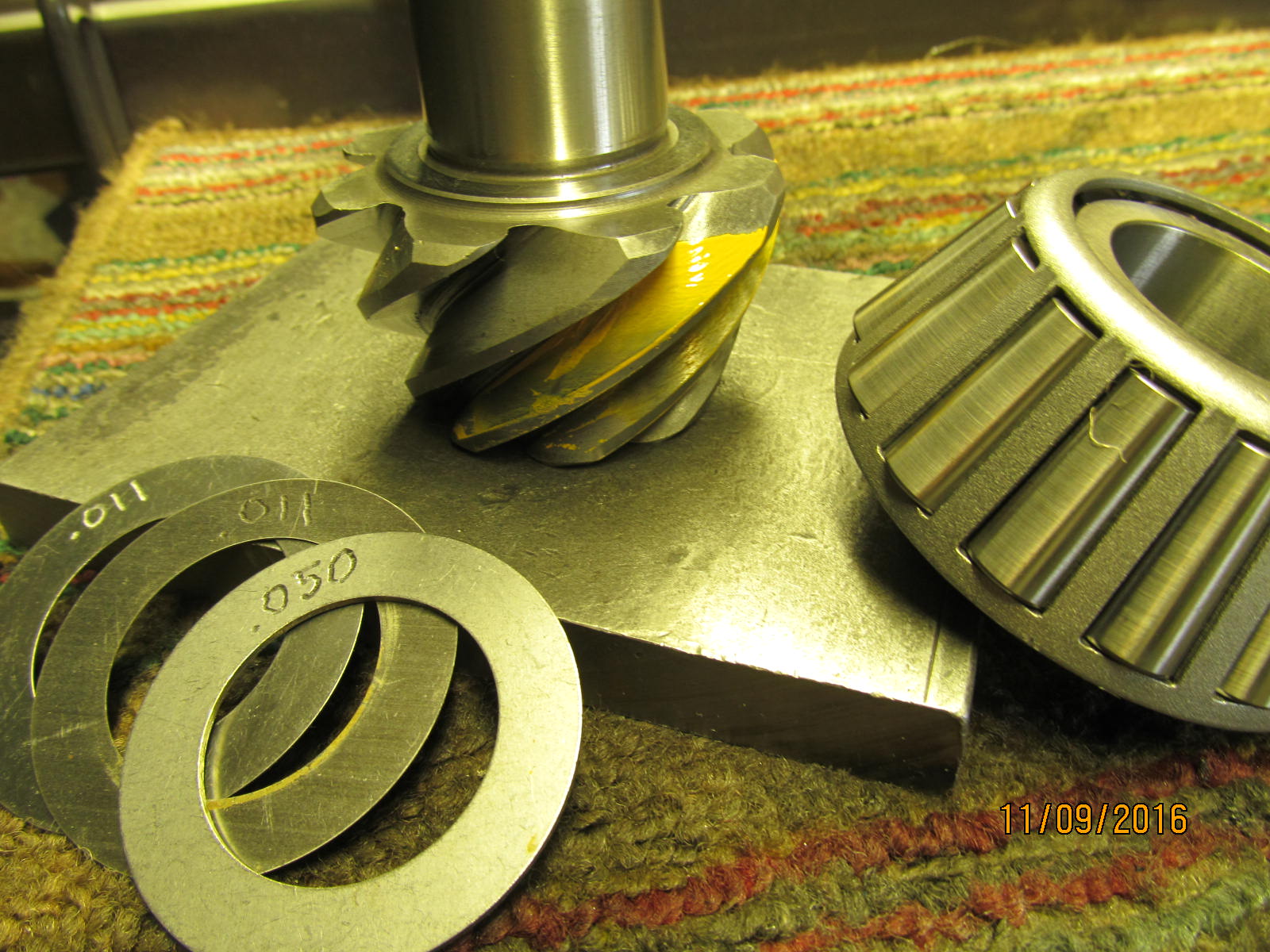

Onto the pinion end of things....076" will be the starter pinion shim to try.

The new bearing is then pressed on.

|

|

|

|

|

Carrier bearings can now be pressed on at the same time.

|

|

|

|

|

Surfaces are checked with a file.

|

|

|

|

Usually, but not always, the ring gear can be tapped down evenly like it is shown here.

No boiling water needed.

|

|

|

|

|

Blue loctite and 70 ft/lbs.

|

|

|

|

|

This Harrop is ready now.

|

|

|

|

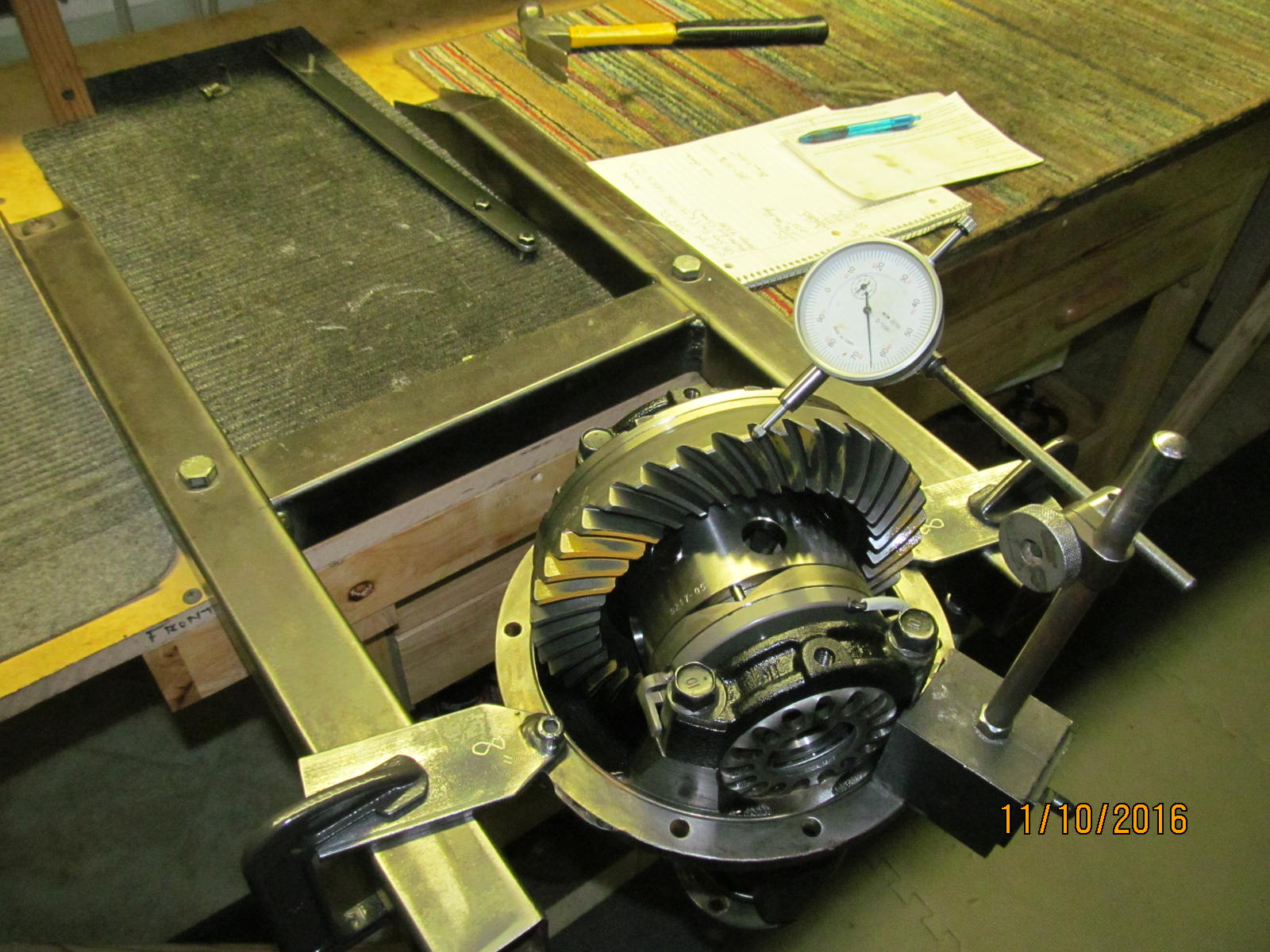

Pinion was loaded in place and then the Harrop was loaded up. Dialed in about

.007" backlash and some carrier bearing preload at the same time.

|

|

|

|

|

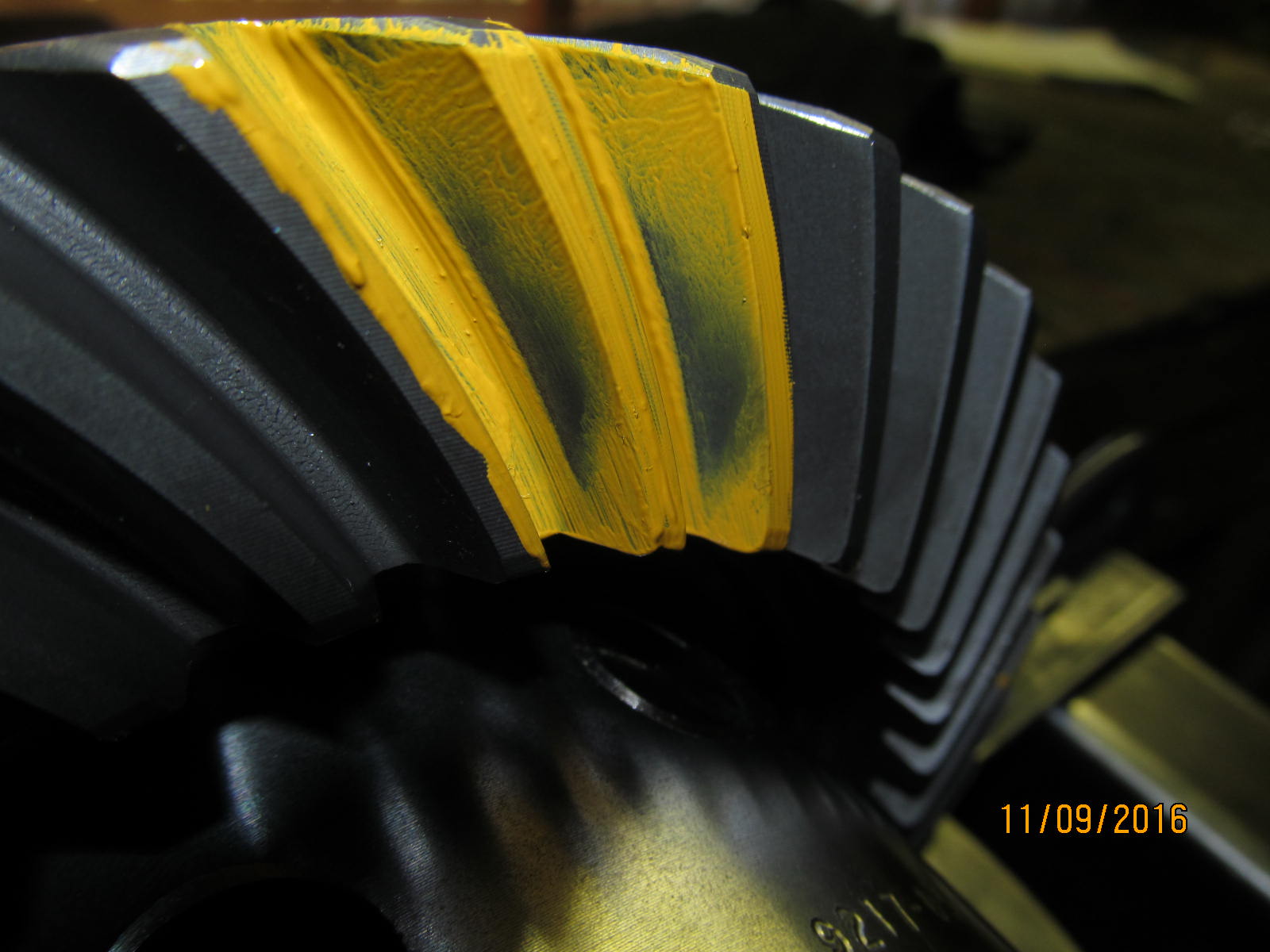

Drive side.....just a little deeper than I like to see.

|

|

|

|

|

Coast side confirms just a tad too deep.

|

|

|

|

A quick check on the tab play and it's a little tight. 2mm or .080" is what the directions "suggest".

I'll massage that by bending the tab out a slight amount.

|

|

|

|

|

Drive side of the pinion tooth is not saying too much here.

|

|

|

|

|

Was 076 but now will use 072". 004 pinion depth change.

|

|

|

|

|

Put it all back together and this as much much better. Drive side looks great.

|

|

|

|

|

Coast looks good.

|

|

|

|

|

Drive side....reverse painted. Looks dead nuts perfect.

|

|

|

|

|

Coast....reverse painted. Looks ideal. Funny how the reverse paints look different than the direct paints.

|

|

|

|

|

New crush sleeve is installed this go-around and the supplied pinion seal is oiled up and installed.

|

|

|

|

|

OOPS. See the rippled damage on the left side when the new seal was installed?

|

|

|

|

Close-up view. Even oiled up, the rubberized seal took on some damage. See the little

mark I made to the left? That way when I remove the seal I can scrutinize the exact area.

|

|

|

|

|

Must have been rough edges that I missed so tear it back out and inspect, file the burr. Much better as shown.

|

|

|

|

Crush the new crush sleeve and measured 15 in/lb start torque. This is with

heavily oiled pinion bearings to minimize dry bearing effects.

|

|

|

|

The 29/64" hole is drilled. It was drilled with the pinion UP and the hole on the low side

so all the shavings dropped down with gravity....kept the bearings and the inside gut of

the 3rd free of debri.

|

|

|

|

The rubber grommet is pushed thru. This operation goes much easier with a

liberal coating of rtv.....it lets the rubber grommet slime its way thru the hole

just like it was greased up. 70 ft/lb on the 4 bearing cap bolts as shown in the pic.

|

|

|

|

Locktab freeplay measured around .100"(2.5mm). The backlash of the ring and pinion was

checked on every other tooth.....I saw minimums of .006" and maximums of .008"

|

|

|

|

The total bearing preload measured 24 in/lb start torque. The known contribution of the

pinion bearings is 15 so whatever is left over is the carrier bearings which is 24-15=9.

|

|

|

|

|

12 volt motorcycle battery check.....almost 3 amps.

|

|

|

|

|

Don't forget to install the last 2 locktabs with 10 plus in/lb of torque.

|

|

|

|

|

The important numbers are dremel'd on the ring gear.

|

|

|

|

|

A final snapshot of the notes and the elocker diff is back on its way to Jeff.

|

|

|

|