|

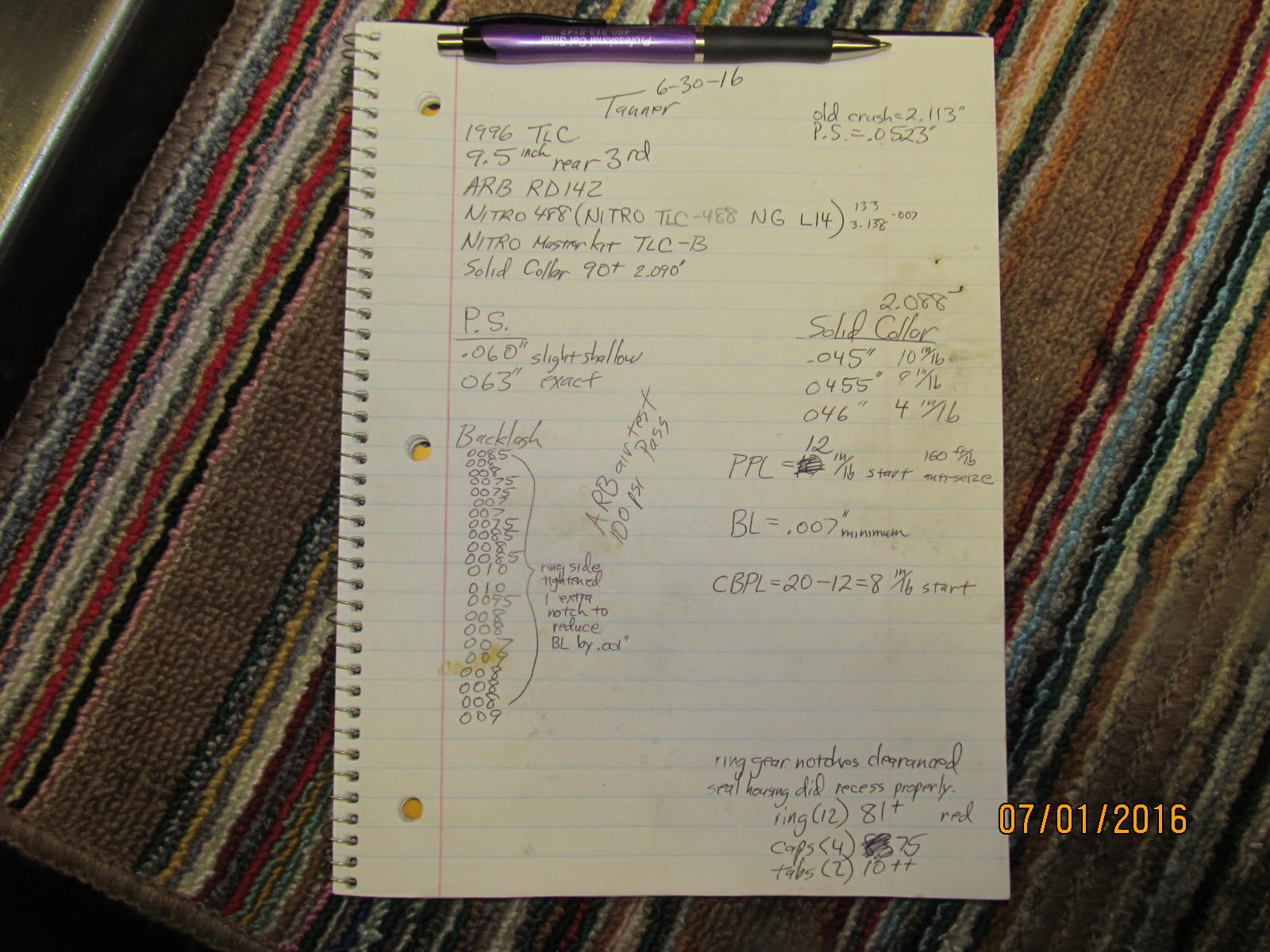

Tanner's 1996 Landcruiser Nitro 488 gear install and ARB RD142

|

|

(50 BIG pics loading)

|

|

July 5 2016

|

|

|

Tanner contacted me about regearing his Cruiser and adding in ARBs on both ends. I sent him the suggested

procedure and, in no time, 2 totes arrived loaded with 3rds/lockers/gears/masterkits

from JustDifferentials.com

|

|

|

|

|

The rear 3rd will be completed first.....and here is the link for the front install.

|

|

|

|

Both bearings caps are removed and the 2 pinion open case put off to the side. The ARB

in the background will replace it.

|

|

|

|

|

Push the pinion out.

|

|

|

|

|

Old seal is pried out.

|

|

|

|

|

Old races removed and new Koyo races tapped in.

|

|

|

|

|

Making sure that it is 100% all the way in.

|

|

|

|

|

New outer race is tapped in.....

|

|

|

|

|

....and, same thing, it is verified to really be seated down 100%.

|

|

|

|

|

It now waits at the pinion install station.

|

|

|

|

|

The Nitro master kit has a decent pinion selection to work with.

|

|

|

|

|

A .060" starter shim will be tried with the Nitro 488 pinion.

|

|

|

|

|

A really good use for a bunch of old bearing inners.

|

|

|

|

|

This is just a preliminary paint test so no crush or solid collar yet.

|

|

|

|

|

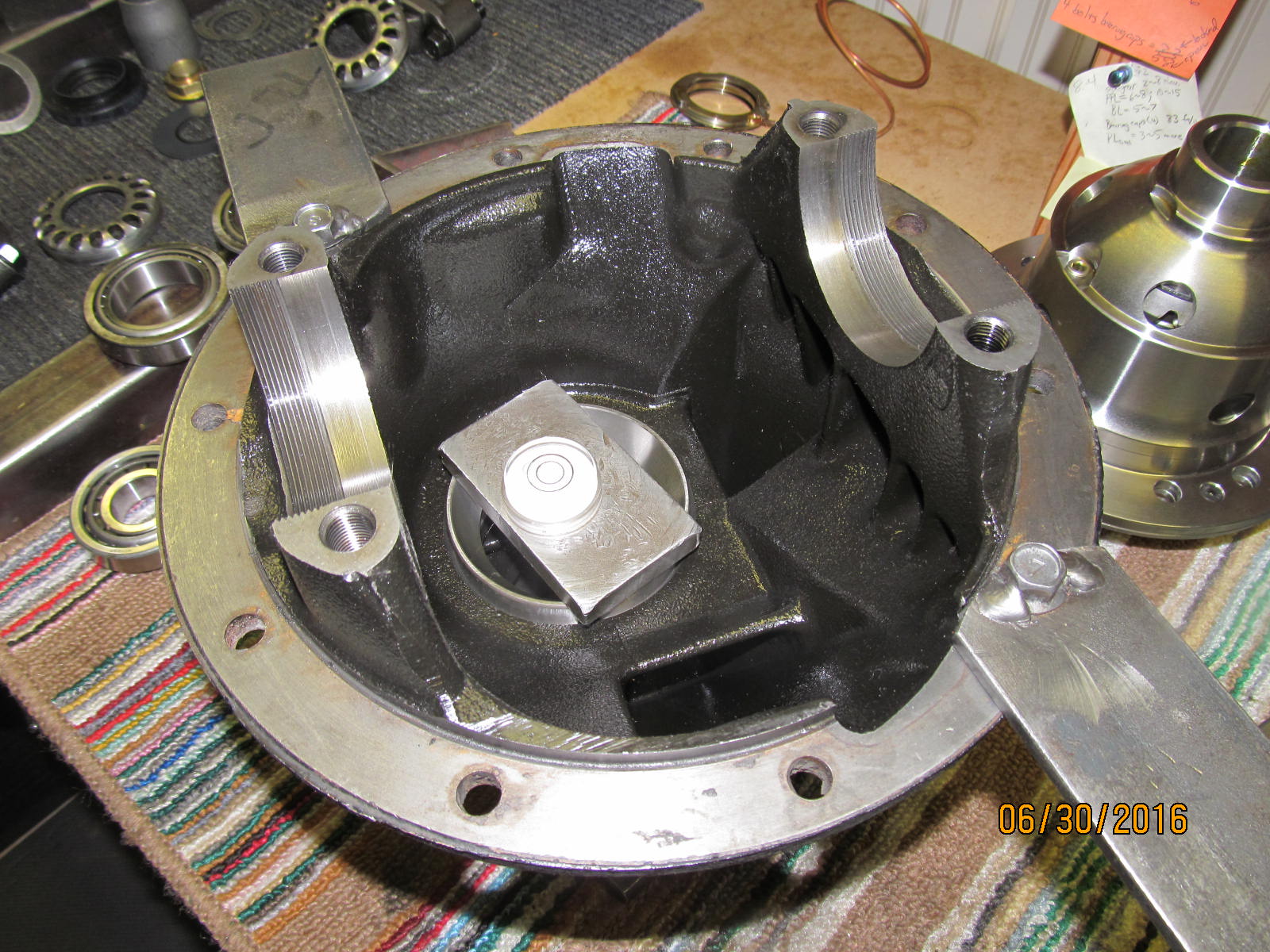

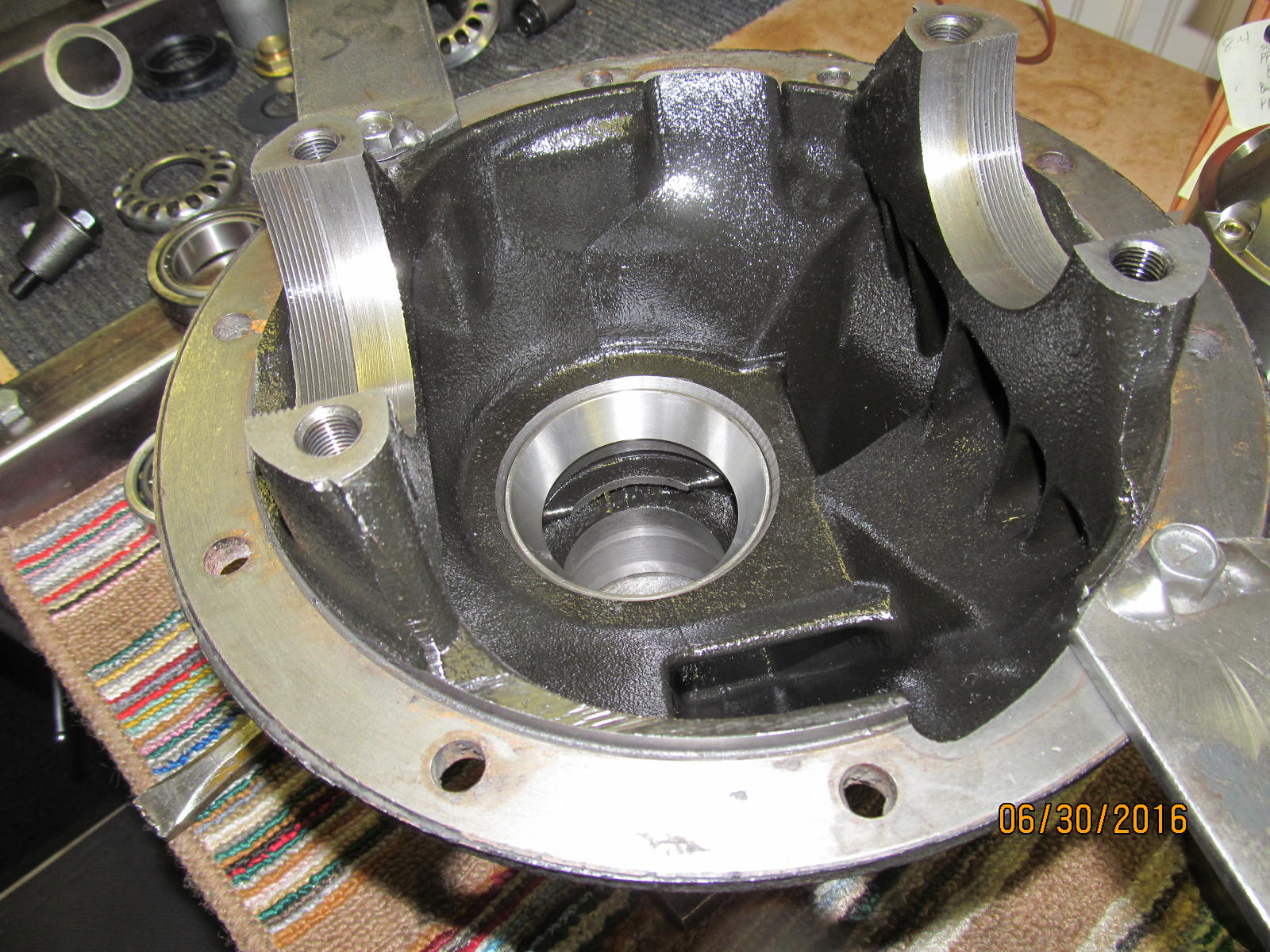

On to the arb....both surfaces were checked for high spots and all looked good.

|

|

|

|

|

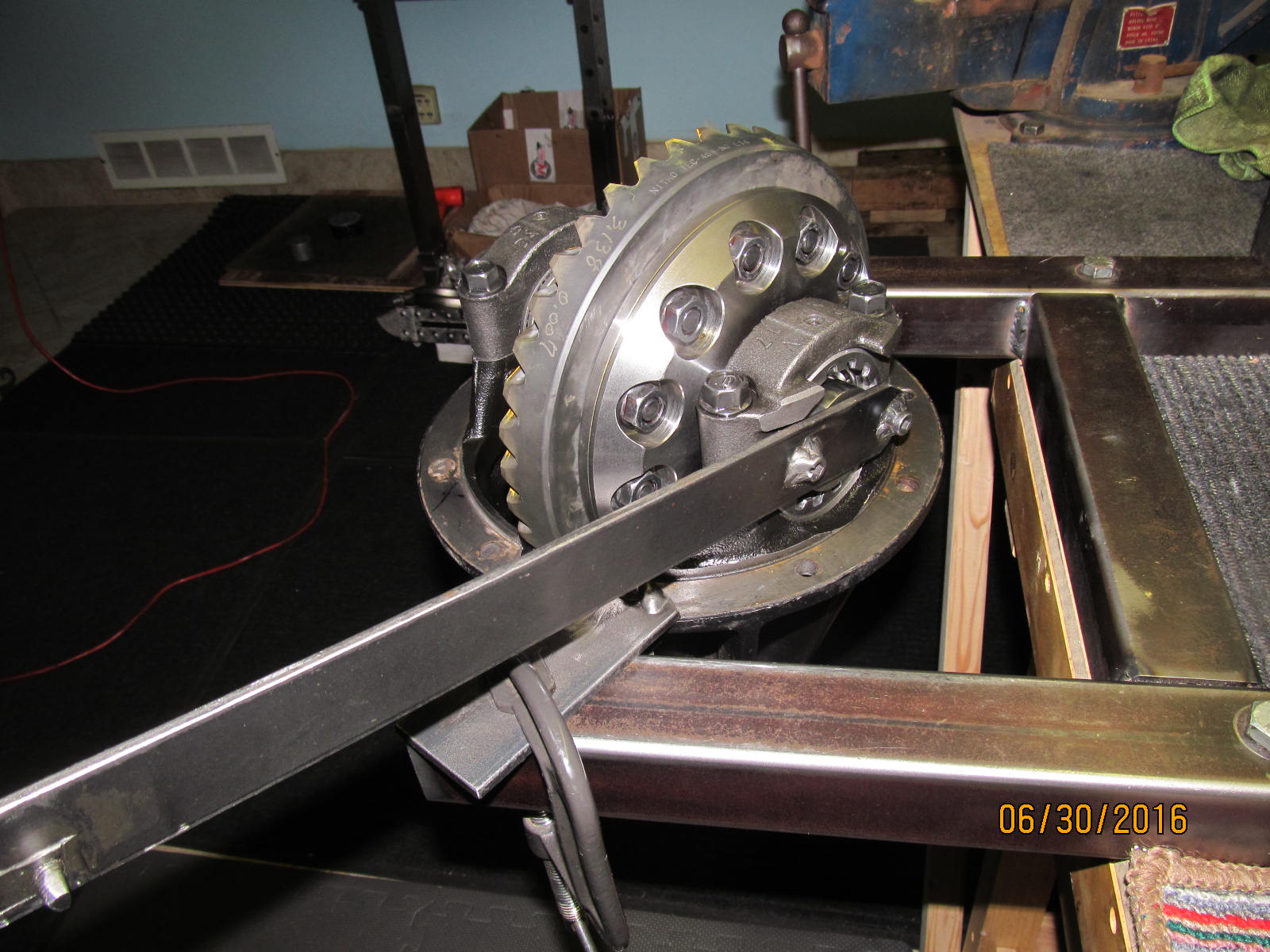

I could have used the press.....it was a tight fit as is the case with almost all ARBs.

|

|

|

|

|

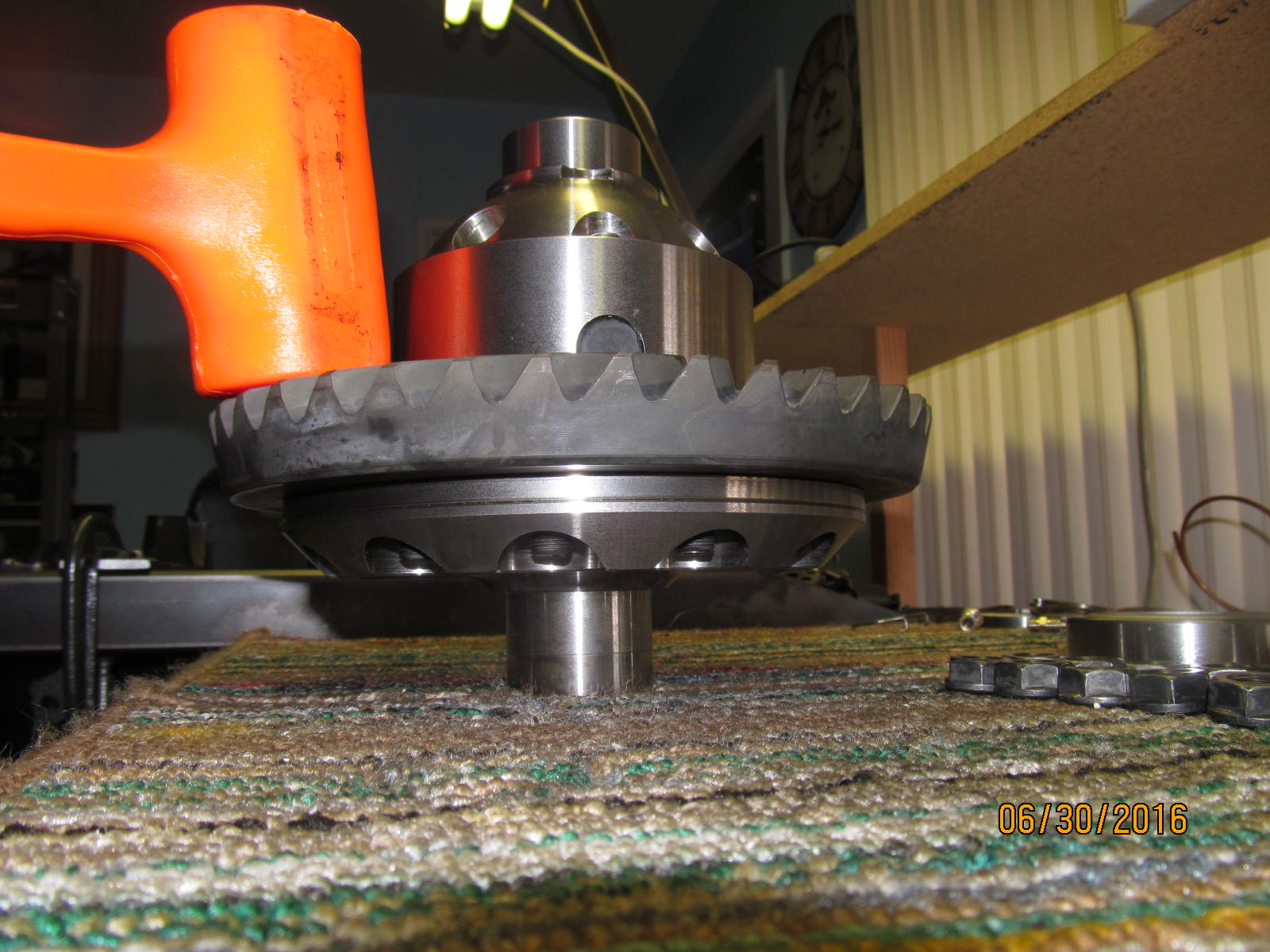

But, with a few dozen hits, it worked its way down. The 12 bolts were placed just perfect.

|

|

|

|

|

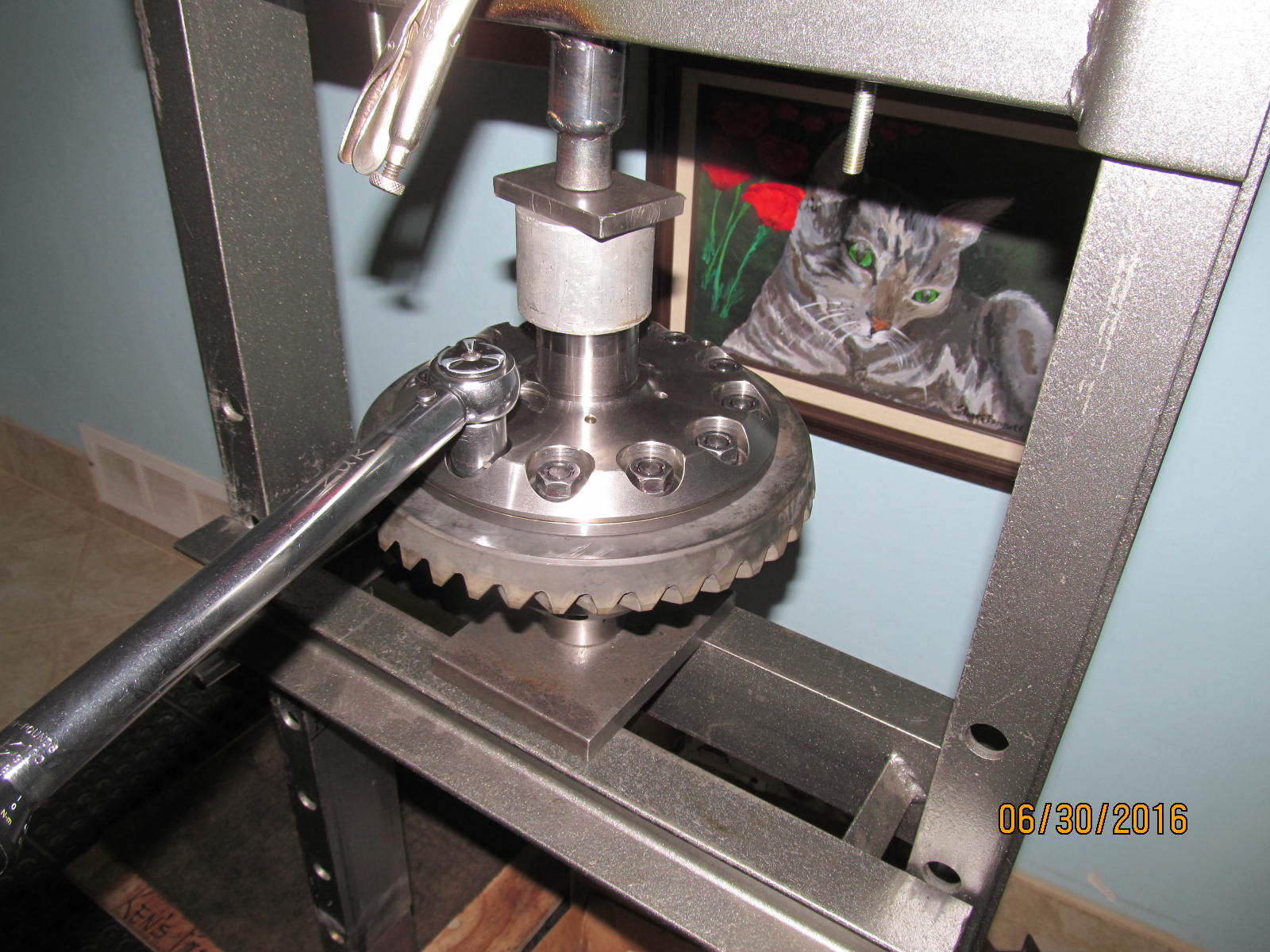

81 ft/lb and red locktight.

|

|

|

|

|

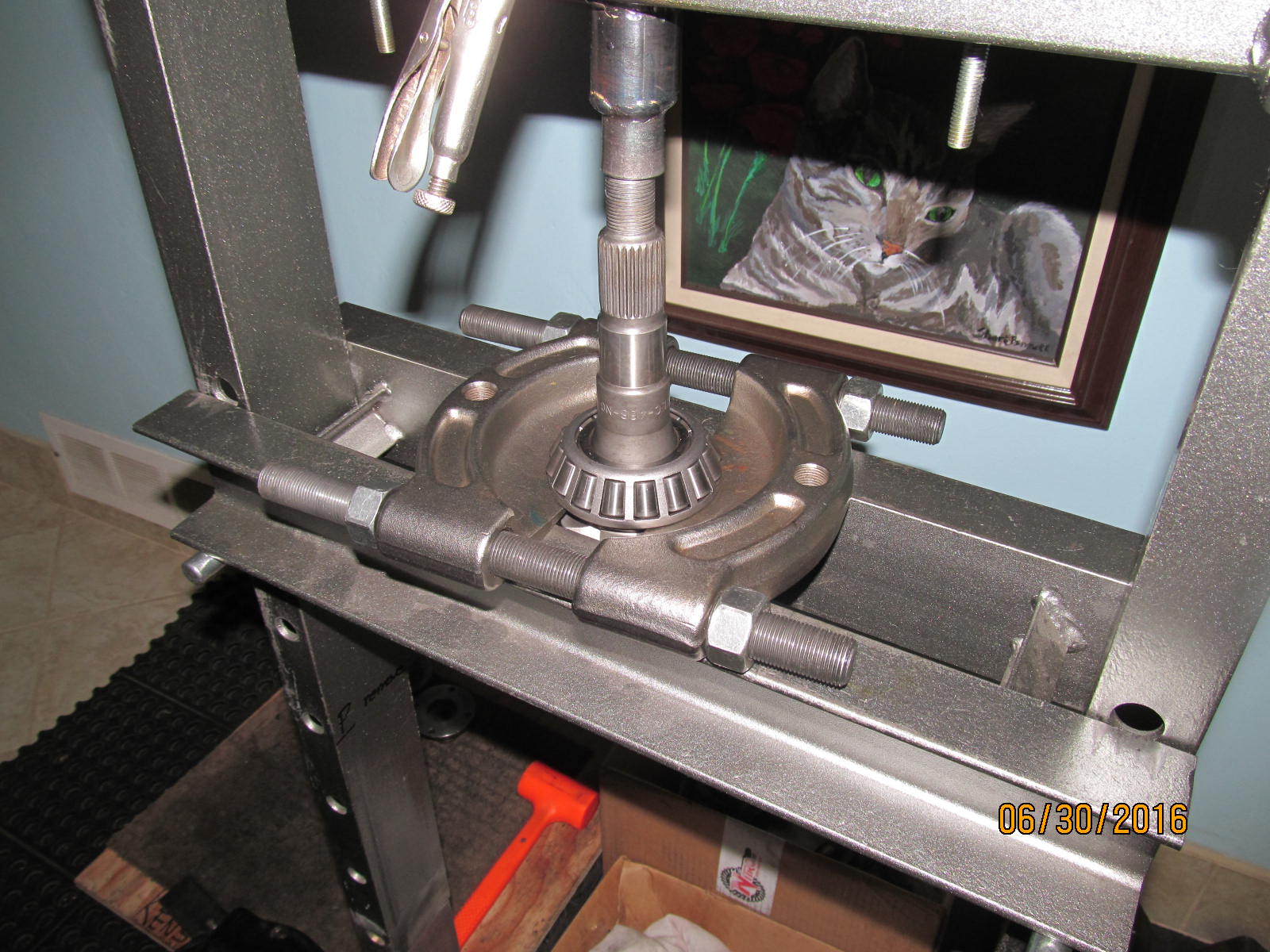

Carrier bearings were a nice tight fit but went on smoothly with the press.

|

|

|

|

Skipped a few pics but basically put the ARB case in....snugged the carrier bearings up.....got the

backlash set to about .007". As shown above the drive side pattern is a bit shallow.

|

|

|

|

|

Coast agrees.

|

|

|

|

|

Drive side on a reverse painted tooth makes it more obvious that it is shallow and favors the edge.

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

Drive side on the pinion tooth....shows the lower comet tail is tucked into the root too hard.

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

So, tear it back down.....off with the pinion bearing.

|

|

|

|

|

And this time, the solid collar is inserted and on the 3rd try a .046" shim was the winner.

|

|

|

|

|

Just .003" deeper and it looks so much better. This is exact depth.

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

The comet tail is shifting out to center a bit.

|

|

|

|

|

Seal check.

|

|

|

|

I have had some seals that pushed on so hard that I had to substitute something else in its place.

This one went on with some resistance but not so much that it starts a fire from the friction.

|

|

|

|

|

Best seal installer I've ever had....

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

Aluminum based anti-seize.

|

|

|

|

|

Tighten until proper PPL is reached...in this case, 12 in/lb start torque.

|

|

|

|

|

Ding! and the pinion end is complete.

|

|

|

|

|

This end is pretty much very straight forward. :) Wheel adjusters are carefully lined up in the proper threads.

|

|

|

|

|

I tightened these 4 bolts to 75 ft/lb because there is an ARB in this equation.

|

|

|

|

|

Total preload was measuring right at 20 in/lb start torque.

|

|

|

|

|

One final tweak and tightened the ring side adjuster wheel 1 notch and then the backlash was right in the zone.

|

|

|

|

|

Last of the ARB parts to be installed.

|

|

|

|

|

I just finished form fitting the soft copper tube in place.

|

|

|

|

|

Now the 2 lock tabs are tightened to 10ft/lb and a little more for good measure.

|

|

|

|

|

ARB is pumped up to 100 psi and this one was left setting overnight and still had 100 in the morning.

|

|

|

|

|

Nice picture

|

|

|

|

|

Final snapshot of the assembly notes.

|

|

|

|

|